Mechanical-electric-hydraulic compound braking system and corresponding vehicle

A compound braking, electro-mechanical-hydraulic technology, applied in the field of vehicles, can solve the problems of high overall cost, abnormal function of ABS and ESP, and high integration requirements, and achieve a safety hazard, abnormal function, integration and function enhancement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

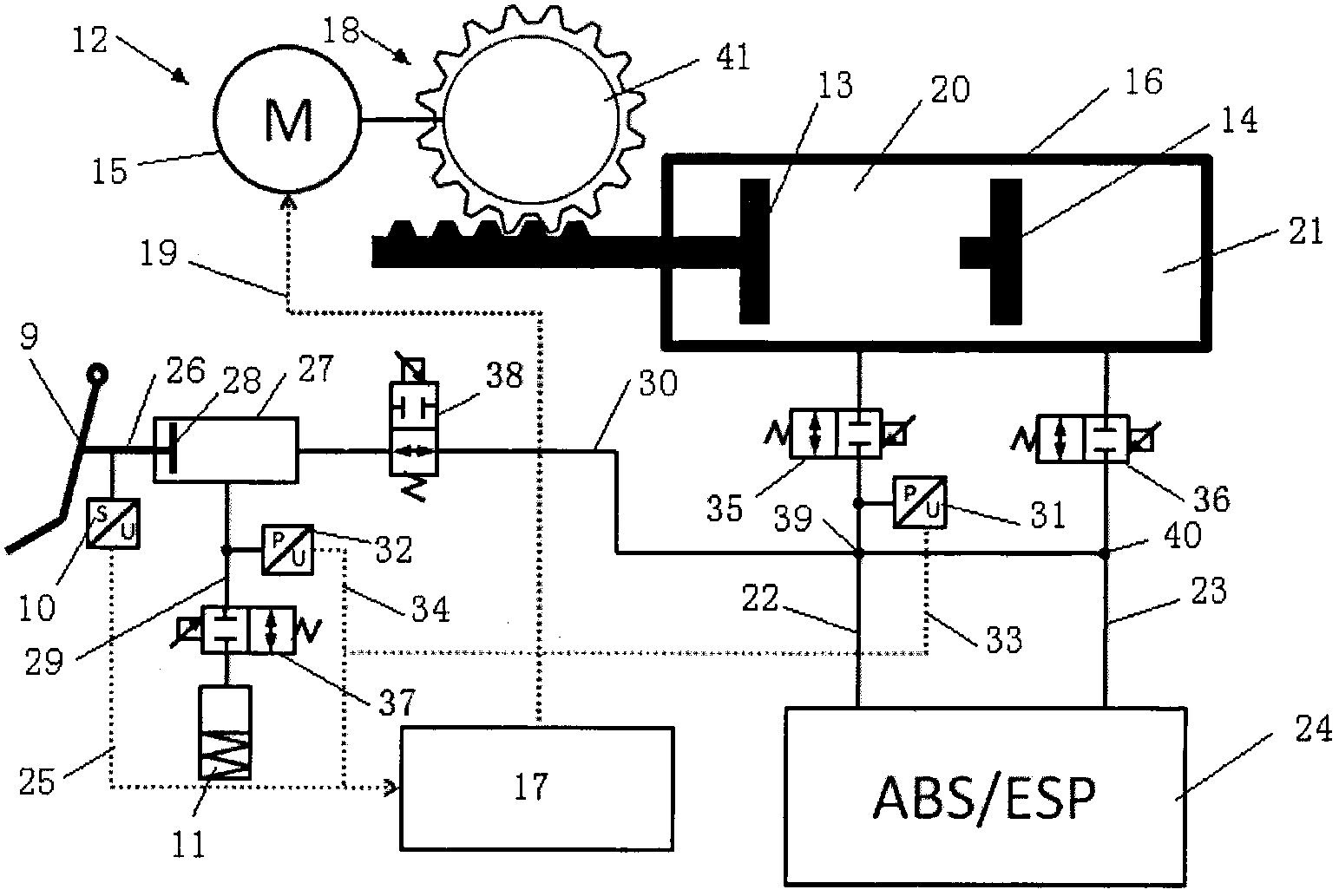

[0021] In the following, specific embodiments of the present invention will be described in more detail with reference to the accompanying drawings in order to better understand the basic idea of the present invention.

[0022] figure 2 A simplified diagram of a fully decoupled electromechanical hydraulic brake system according to an exemplary embodiment of the present invention is shown.

[0023] Such as figure 2 As shown, the fully decoupled electromechanical-hydraulic brake system mainly includes: an electronically controlled linear motion module 12 , a booster master cylinder 16 , a pedal simulator 11 and a brake pedal 9 . The brake pedal 9 is equipped with a displacement sensor 10 which makes it possible to determine the velocity and displacement of the brake pedal 9 when it is depressed.

[0024] In this exemplary embodiment, the electronically controlled linear motion module 12 includes an electronic control unit 17 and a linear motion mechanism 18 . The electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com