Feedforward signal control method in boiler steam temperature automatic control system

A feedforward signal and disturbance signal technology, applied in the field of control, can solve the problems of large dynamic error of steam flow measurement and inability to measure boiler combustion disturbance, and achieve the effects of low cost, improved quality, and reduced steam temperature fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

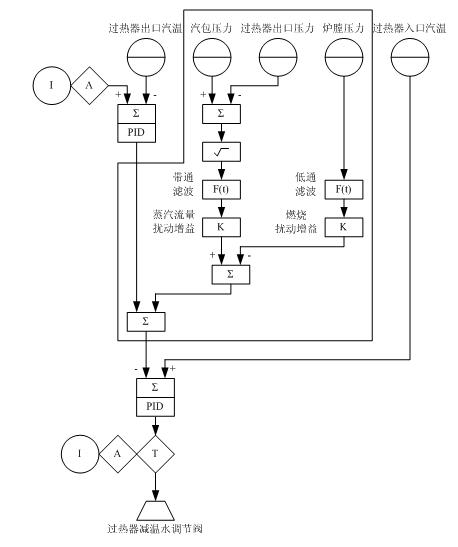

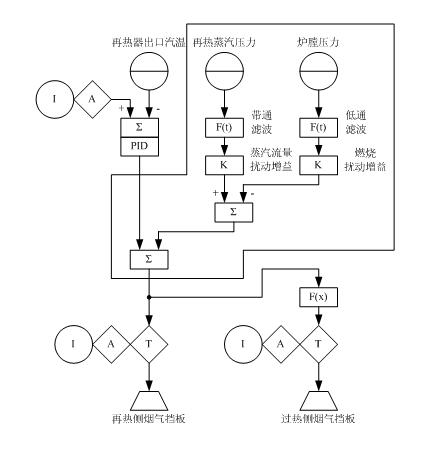

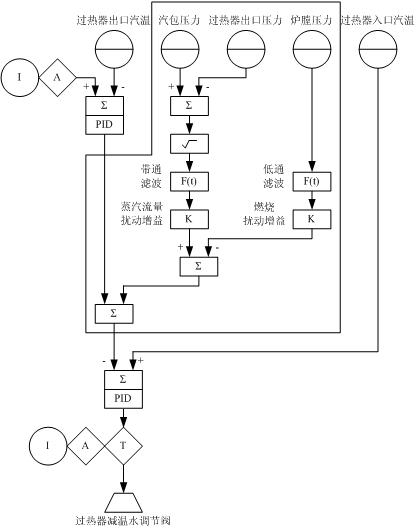

[0038]Aiming at the problem of poor control quality of boiler steam temperature under combustion disturbance and steam flow disturbance, the present invention constructs a feed-forward signal that can reflect boiler combustion disturbance and steam flow disturbance, and uses this signal to control typical boiler steam temperature control system It is improved to form a feedforward-feedback compound control system, which can improve the stability of boiler steam temperature control.

[0039] Technical scheme of the present invention is implemented in the following 5 steps:

[0040] 1. Raw signal calibration

[0041] The present invention needs to use the following measurement signals of the boiler: boiler furnace pressure pf, boiler drum pressure (or steam-water separator pressure) pd, boiler superheater outlet steam pressure pb, boiler reheater outlet steam pressure pr. Among them: the furnace pressure is used to construct the boiler combustion disturbance signal;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com