System and method for improving operation capacity of SCR (Silicon Controlled Rectifier) denitration device in electric power plant

A technology of operation capability and denitration, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problem that the denitration device 10 cannot be put into operation normally, the flue gas temperature at the outlet of the economizer 3 is lowered, and the water supply flow cannot be adjusted. It can improve the effective operation time, prolong the effective service life, and improve the denitrification ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

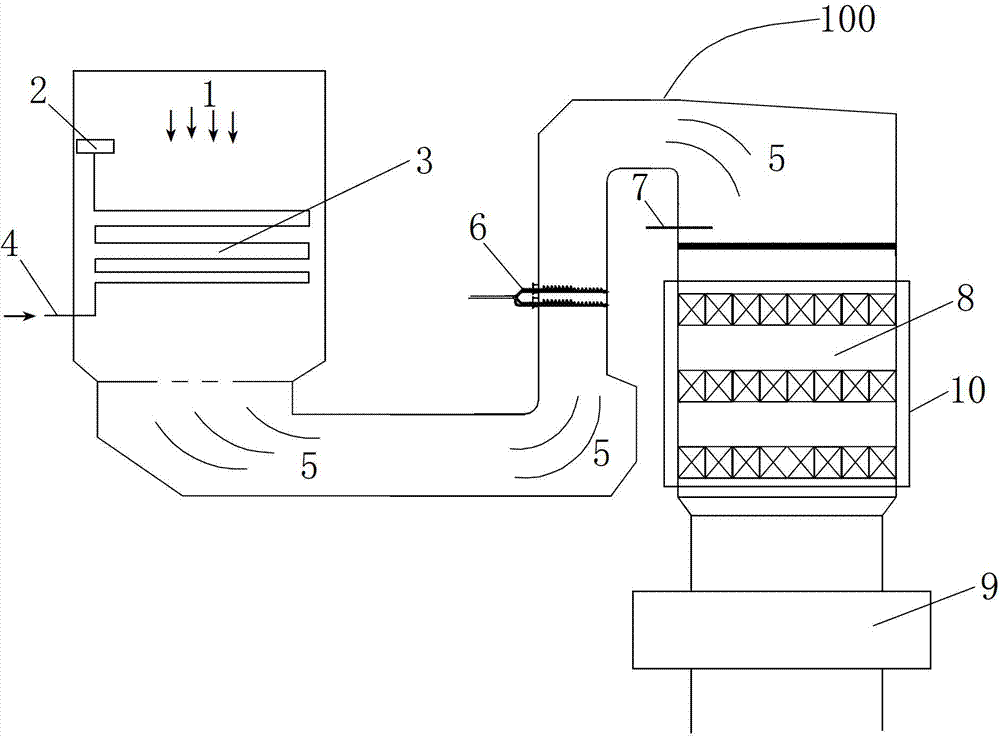

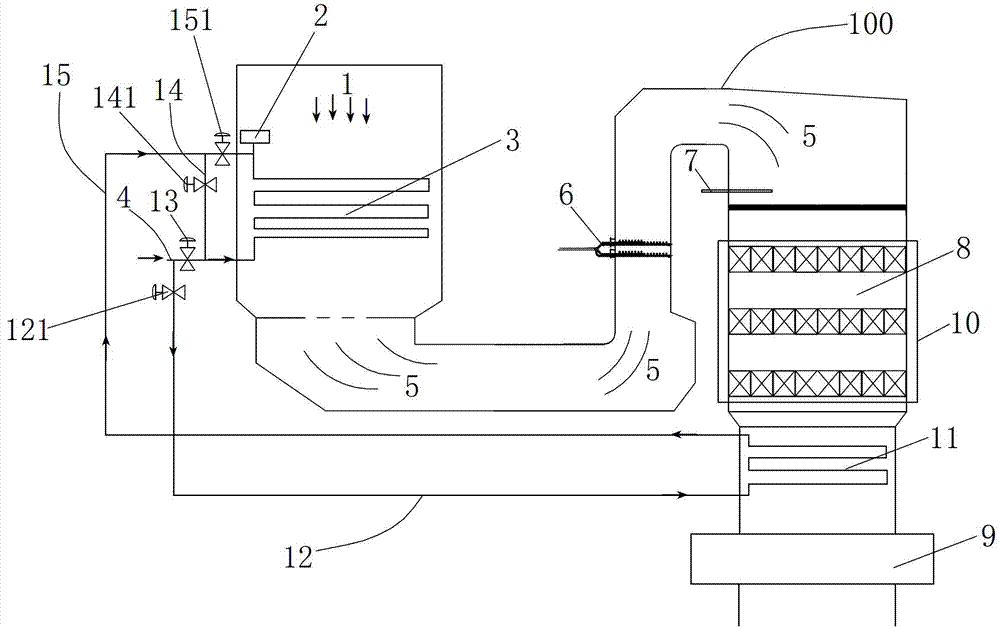

[0024] Such as figure 2 A system for improving the operation capacity of the SCR denitrification device in a power plant is shown, the system includes a steam drum 2, an economizer 3, a deflector 5, an ammonia Injection device 6, temperature sensor 7, denitrification device 10 and air preheater 9, the water inlet of economizer 3 is connected with economizer feed water inlet pipeline 4, and the water outlet of economizer 3 is connected with steam drum 2 The denitrification catalyst 8 is placed in the denitrification device 10, and the flue gas 1 passes through the denitrification device 10, the air preheater 9, and other follow-up equipment after heat exchange through various heat exchange equipment in the boiler flue. The system also includes a low-temperature heat exchanger 11, which is arranged in the flue between the denitrification device 10 and the air preheater 9, and the feedwater inlet pipeline 4 of the economizer is bypassed with the low-temperature heat exchanger 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com