Isothermal low-temperature CO shift reactor

A reactor and low-temperature technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of difficult operation and control, burnout catalyst, and large steam loss, so as to reduce steam consumption and gas resistance , the effect of low water vapor ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

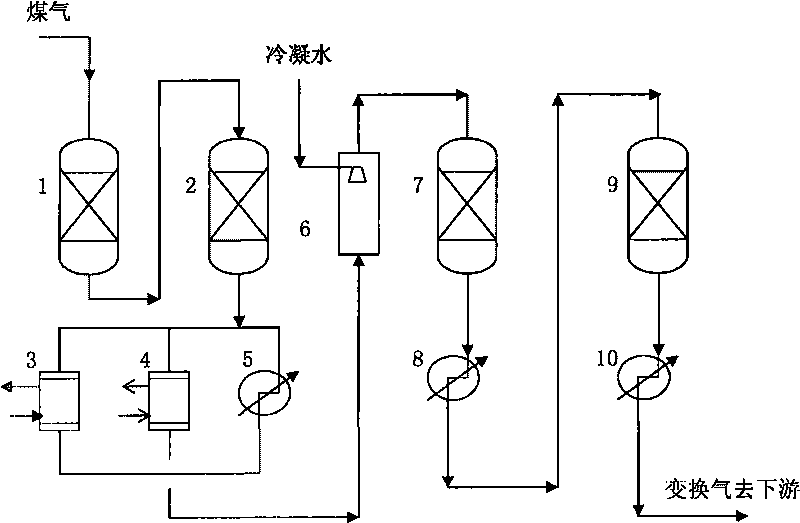

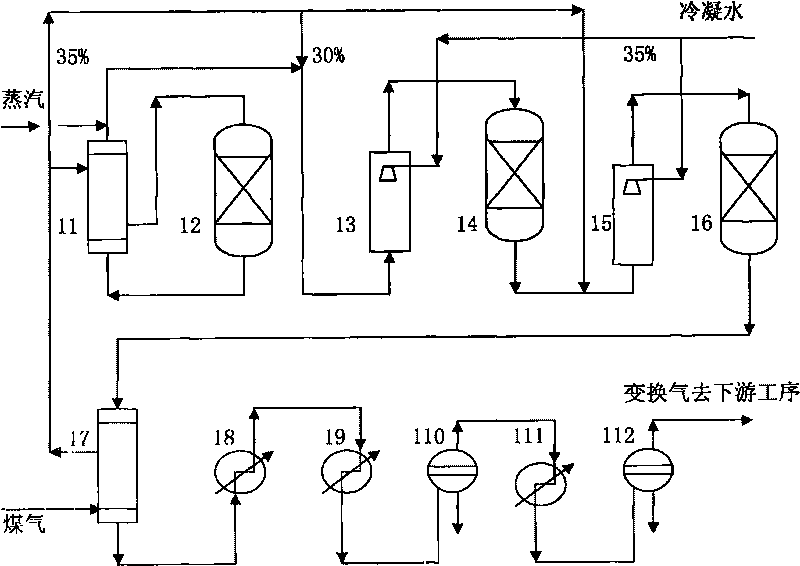

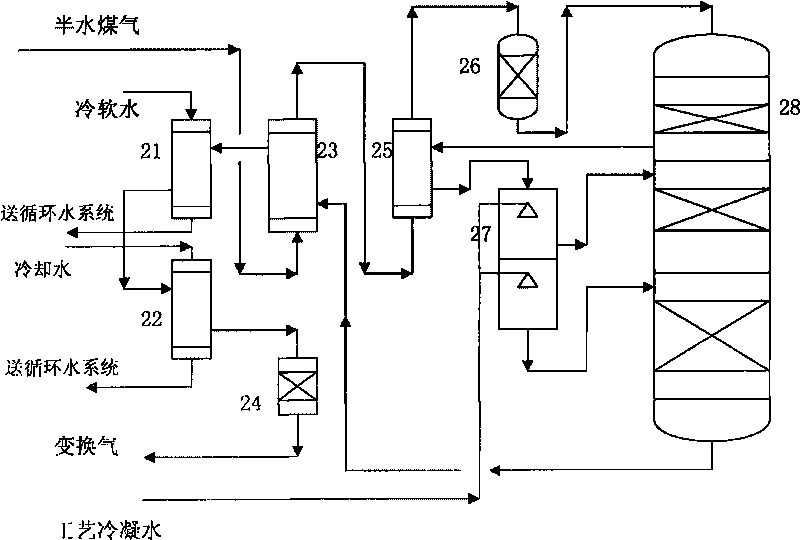

[0077] Such as figure 1 As shown, the isothermal low-temperature CO shift reactor has an upright cylindrical shell 38 whose upper and lower ends are sealed. , the cavity between the upper tube plate 32 and the upper head of the cylindrical shell 38 is a water chamber 314, the cavity between the upper tube plate 32 and the lower tube plate 33 is a steam chamber 315; There is a radial basket 37 whose bottom is a head and the side wall is distributed with a number of ventilation holes. The top of the radial basket 37 is connected with the lower tube plate 33; Annulus 316; the central tube 35 with no closed top in the middle of the radial basket 37 and a number of ventilation holes distributed on the tube wall. The lower end of the central tube 35 is the conversion gas outlet 317 located below the bottom of the cylindrical shell 38; A plurality of inverted U-shaped pipes 36 are provided, and the two ports of the U-shaped pipes 36 communicate with the outer annular pipe 310 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com