LCP (Liquid Crystal Polymer) or fluoride polymer high-frequency high-transmission double-sided copper clad laminate and FPC (Flexible Printed Circuit)

A fluorine-based polymer, double-sided copper foil technology, used in electronic equipment, lamination, applications, etc., can solve the problems of difficult control of circuit board impedance value, inability to use fast press equipment, affecting copper plating continuity, etc. , to achieve stable dk/df performance, good impedance control, and good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

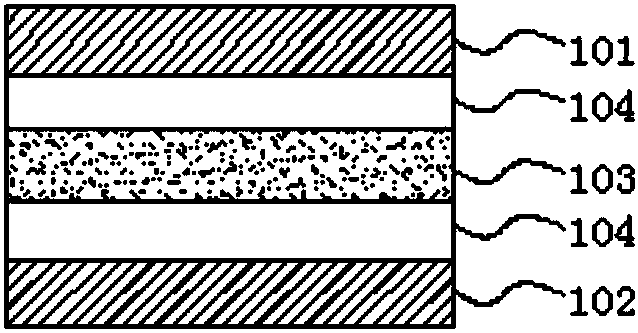

[0068] Embodiment 1: An LCP or fluorine-based polymer high-frequency high-transmission double-sided copper foil substrate, such as figure 1 As shown, the double-sided copper foil substrate is sequentially composed of the first copper foil layer 101, the first insulating polymer layer 104, the first very low dielectric adhesive layer 103, the first insulating polymer layer 104 and the second Two copper foil layers 102 are formed.

[0069] In this embodiment, preferably, the thickness of the first copper foil layer and the second copper foil layer are both 6-18 μm; the thickness of the ultra-low dielectric adhesive layer is 10-50 μm; the first The thickness of the insulating polymer layer is 12.5-25 μm.

[0070] Both the first copper foil layer and the second copper foil layer are rolled copper foil layers (RA / HA / HAV2) or electrolytic copper foil layers (ED).

[0071] In this embodiment, the preparation method of the double-sided copper foil substrate is carried out according ...

Embodiment approach 2

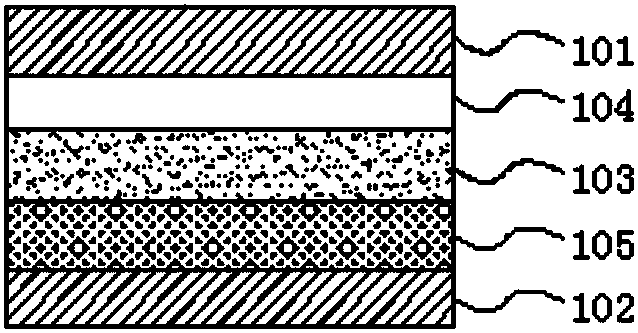

[0078] Embodiment 2: An LCP or fluorine-based polymer high-frequency high-transmission double-sided copper foil substrate, such as figure 2 As shown, the structure is similar to Embodiment 1, the difference is that: the double-sided copper foil substrate is sequentially composed of the first copper foil layer 101, the first insulating polymer layer 104, the first ultra-low dielectric adhesive layer 103, a second insulating polymer layer 105 and a second copper foil layer 102.

[0079] In this embodiment, the preparation method of the double-sided copper foil substrate is carried out according to the following steps:

[0080] Step 1. Apply LCP polymer or fluoropolymer resin on one side of the first copper foil layer, remove the solvent at 60-100°C, and then react at 300°C for 10 hours to form the first insulating layer. polymer layer;

[0081] Step 2, coating the ultra-low dielectric adhesive on the other side of the first insulating polymer layer, drying and pressing to obt...

Embodiment approach 3

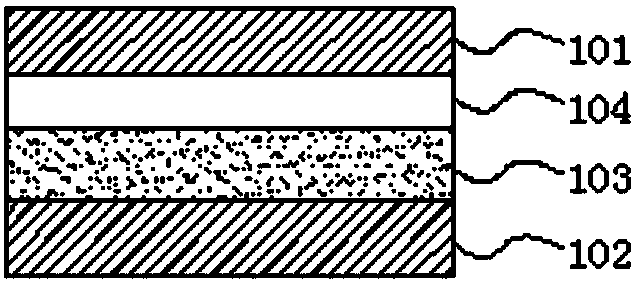

[0085] Embodiment 3: An LCP or fluorine-based polymer high-frequency high-transmission double-sided copper foil substrate, such as image 3 As shown, the structure is similar to Embodiment 1, the difference is that: the double-sided copper foil substrate is sequentially composed of the first copper foil layer 101, the first insulating polymer layer 104, the first ultra-low dielectric adhesive layer 103 and the second copper foil layer 102.

[0086] The total thickness of the first copper foil layer, the first insulating polymer layer, the first ultra-low dielectric adhesive layer and the second copper foil layer is 9-170 μm.

[0087] In this embodiment, the preparation method of the double-sided copper foil substrate is carried out according to the following steps:

[0088] Step 1. Apply LCP polymer or fluoropolymer resin on one side of the first copper foil layer, remove the solvent at 60-100°C, and then react at 300°C for 10 hours to form the first insulating layer. polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com