Mold assembly

a mold and assembly technology, applied in the field of molds, can solve the problems of affecting the work efficiency of technicians, affecting the work efficiency of workers, and affecting the work efficiency of workers, and achieve the effect of greater thermal expansion and durable stainless steel shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

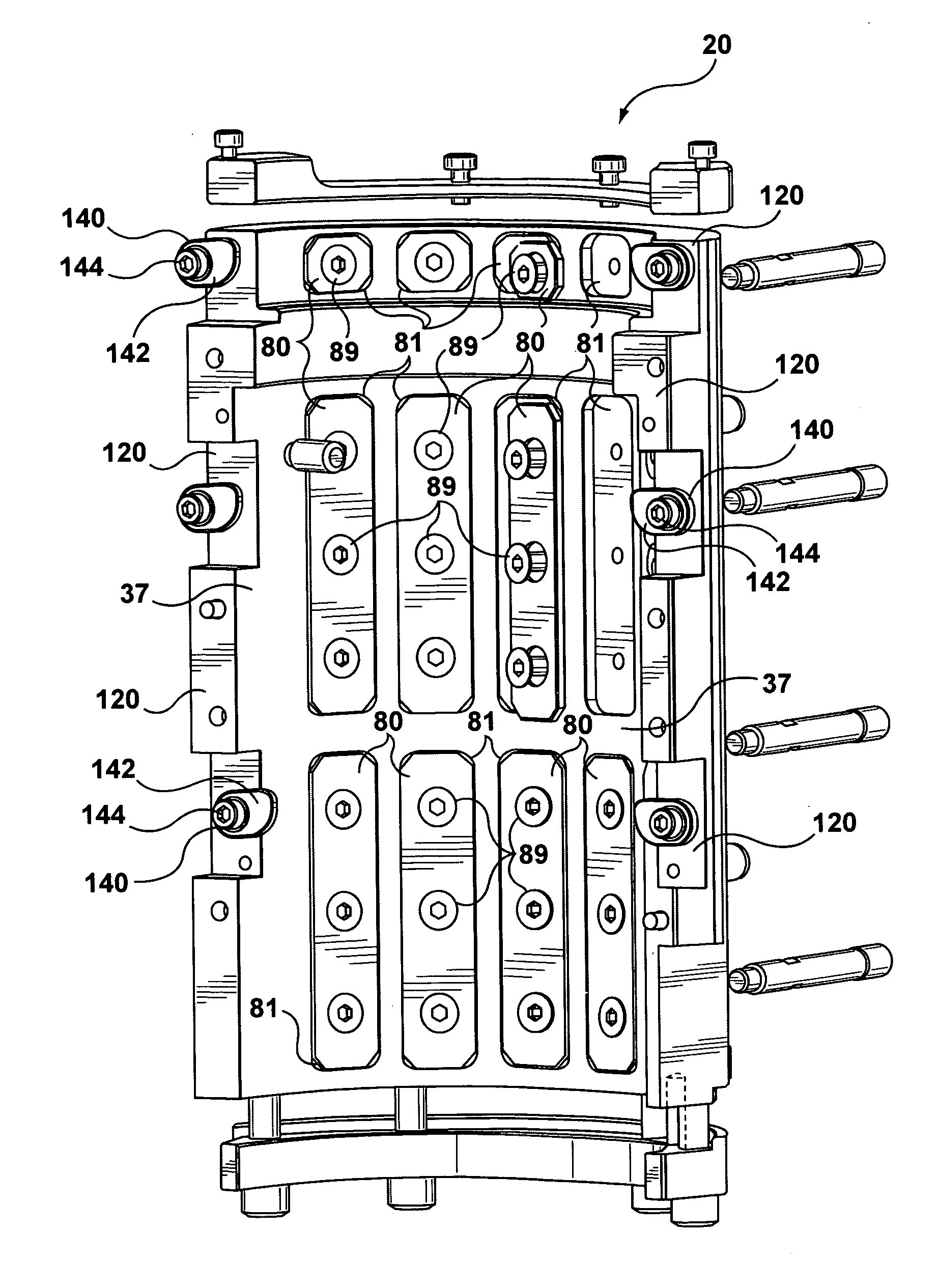

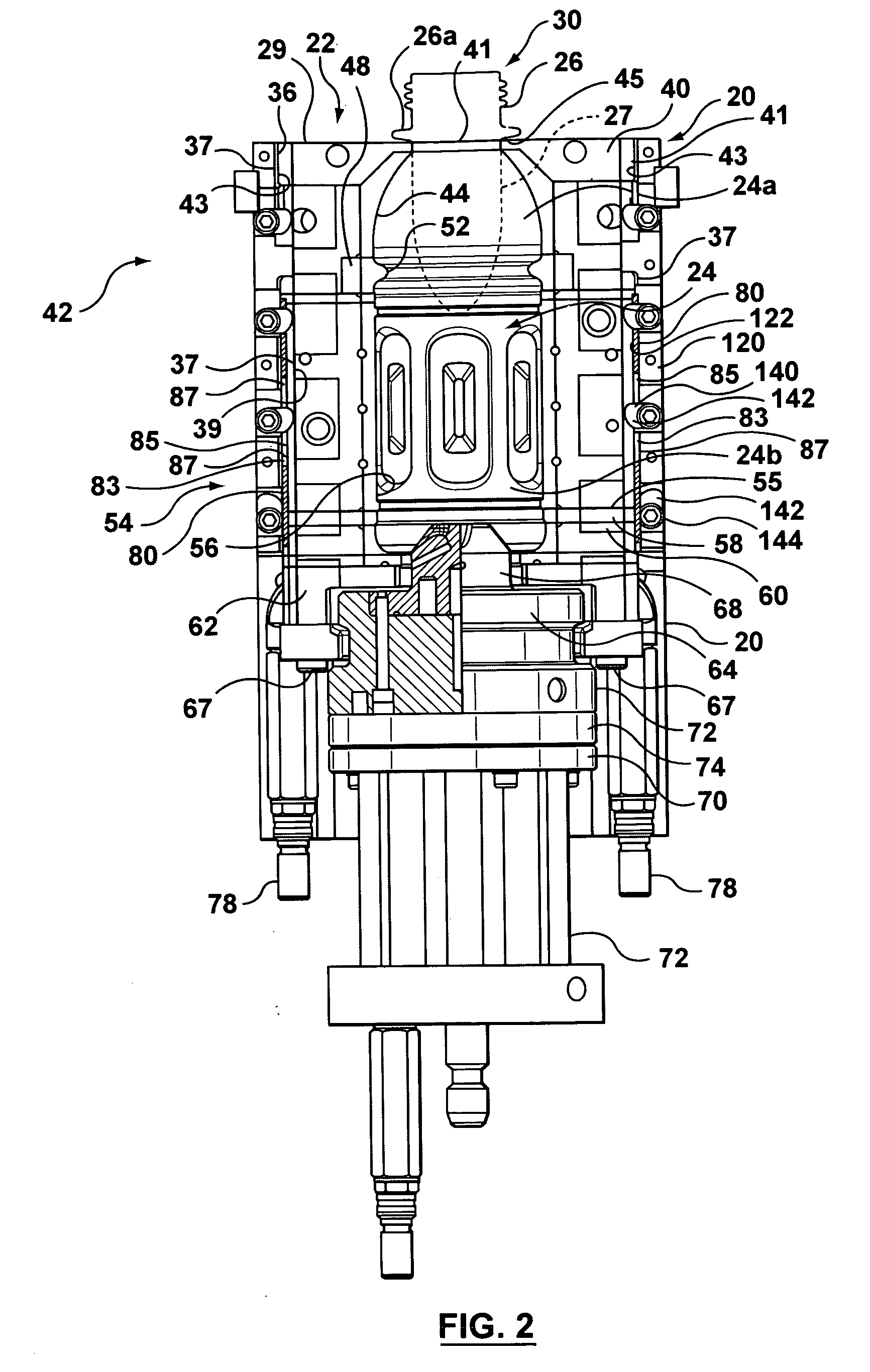

[0022]Referring to the drawings, the embodiments of the present invention are described. While the mold assembly described herein is adapted for making a hot fill PET bottle, it should be understood that the mold apparatus shown can be used for cold fill operations as well as for the manufacture of other types of containers where the mold face is changed, such as for example, soft drinks, cleansers and detergent-type containers, to name a few. In the exemplary embodiment, the mold half shell is made from stainless steel and the mold half carrier is made from aluminum. However, it should be understood that the mold half shells and the mold half carriers may be made from similar materials suitable for use in a mold assembly, such as for example, a stainless steel shell and carrier, or an aluminum shell and carrier.

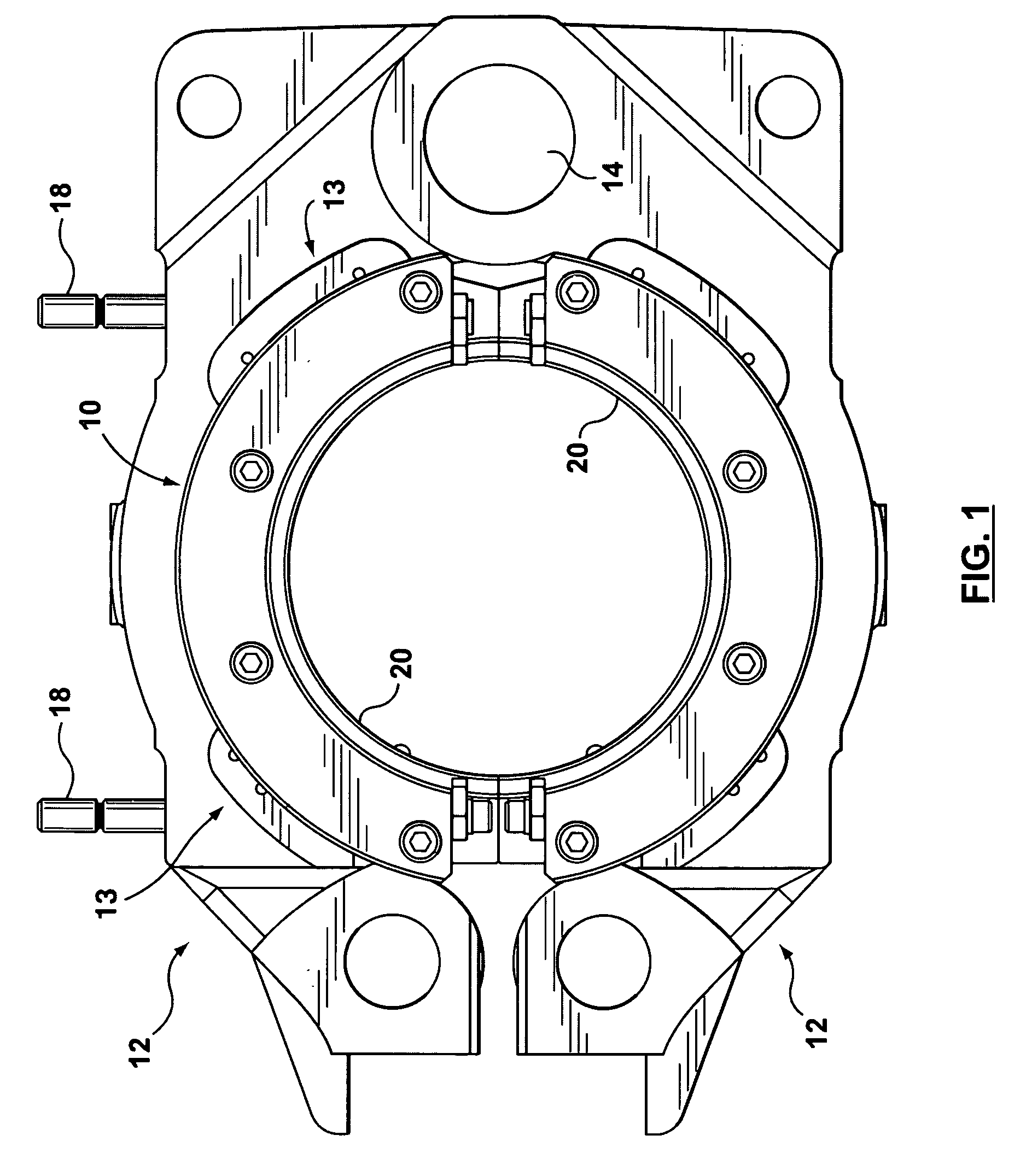

[0023]Referring to FIGS. 1 and 2, the mold assembly 10 is supported by a pair of support arms 12 which pivot about a pivot pin or axis 14. A lever arm (not shown in figures)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| mechanical | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com