Heat treatment apparatus

a technology of heat treatment apparatus and heating chamber, which is applied in lighting and heating apparatus, furnace types, furnaces, etc., can solve the problems of metal contamination of wafers, affecting the heating effect, and causing damage, so as to prevent direct contact, reduce pressure, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

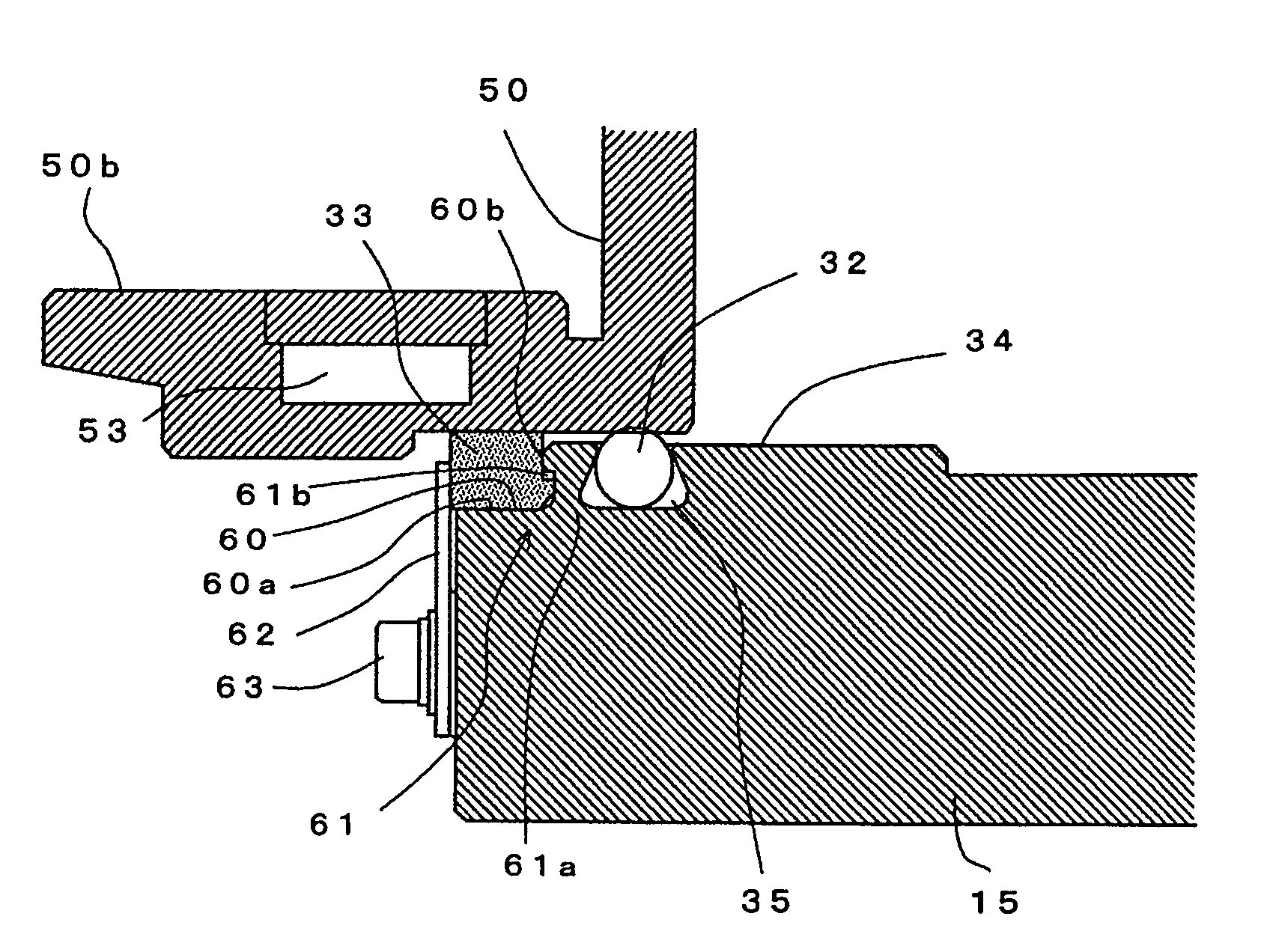

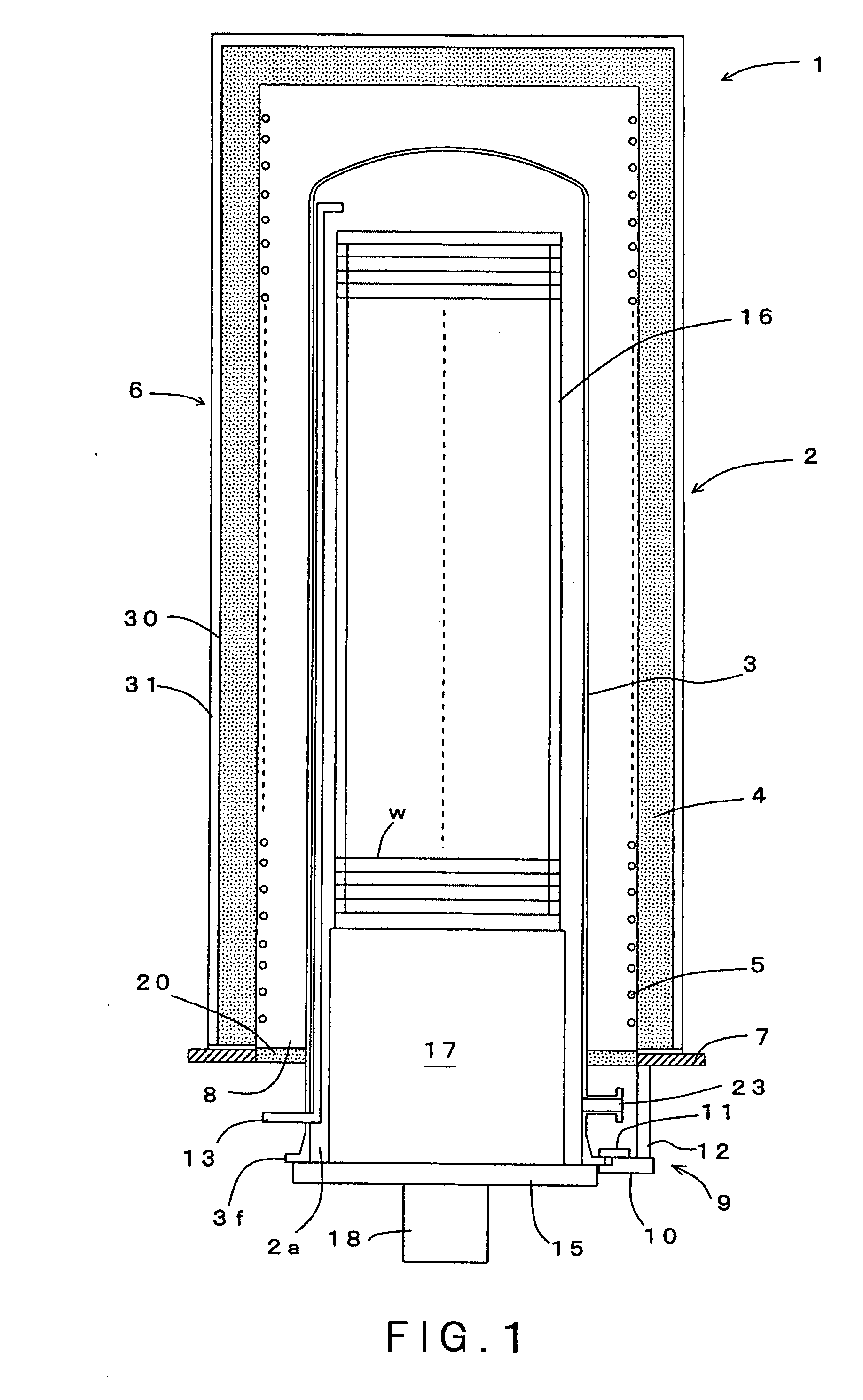

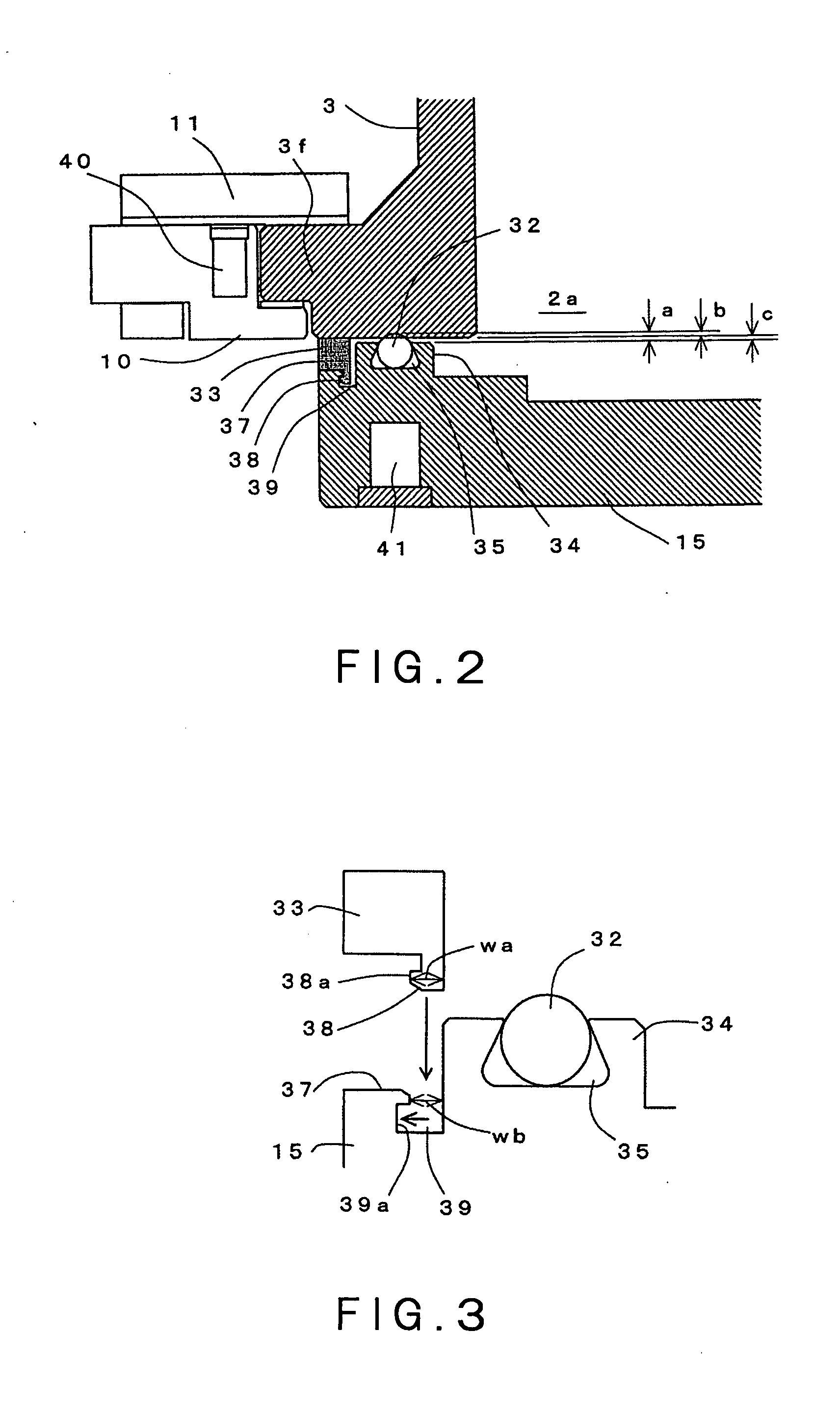

[0031]Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. FIG. 1 is a vertical cross-sectional view schematically showing a heat treatment apparatus in the present invention. FIG. 2 is an enlarged cross-sectional view showing a main portion of the heat treatment apparatus. FIG. 3 is a diagram explaining a structure for mounting a contact-preventing member on a lid. FIG. 4 is a plan view of the contact-preventing member.

[0032]Referring to FIG. 1, reference number 1 denotes a vertical heat treatment apparatus that is one type of semiconductor manufacturing apparatus. The heat treatment apparatus 1 has a vertical heat treatment furnace 2, which is adapted to accommodate simultaneously a large number of process objects, such as semiconductor wafers W, so as to perform a heat treatment (thermal process) such as low-pressure diffusion process to those wafers. The heat treatment furnace 2 primarily includes: a processing v...

second embodiment

[0054]FIG. 9 is a vertical cross-sectional view schematically showing a heat treatment apparatus in the present invention. FIG. 10 is an enlarged cross-sectional view showing main parts of the heat treatment apparatus. In FIG. 9, reference number 1 denotes a vertical heat treatment apparatus that is one type of semiconductor manufacturing apparatus. The heat treatment apparatus 1 has a vertical heat treatment furnace 2, which is adapted to accommodate simultaneously a large number of process objects, such as semiconductor wafers W, so as to perform a heat treatment (thermal process) such as low-pressure diffusion process to those wafers. The heat treatment furnace 2 primarily includes: a processing vessel (a vessel main body) 3 that accommodates the wafers W at multiple levels to perform a predetermined heat treatment to the wafers W; and a heater 6 surrounding the processing vessel 3 to heat the wafers W.

[0055]The heat treatment apparatus 1 has a base plate 7 for installing the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com