On-load tap-changer for high-voltage power transmission transformer and control method of on-load tap-changer

A technology of on-load tapping and high-voltage power transmission, applied in the field of transformers, can solve problems such as poor safety, achieve high reliability, reduce design difficulty and control complexity, and have long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

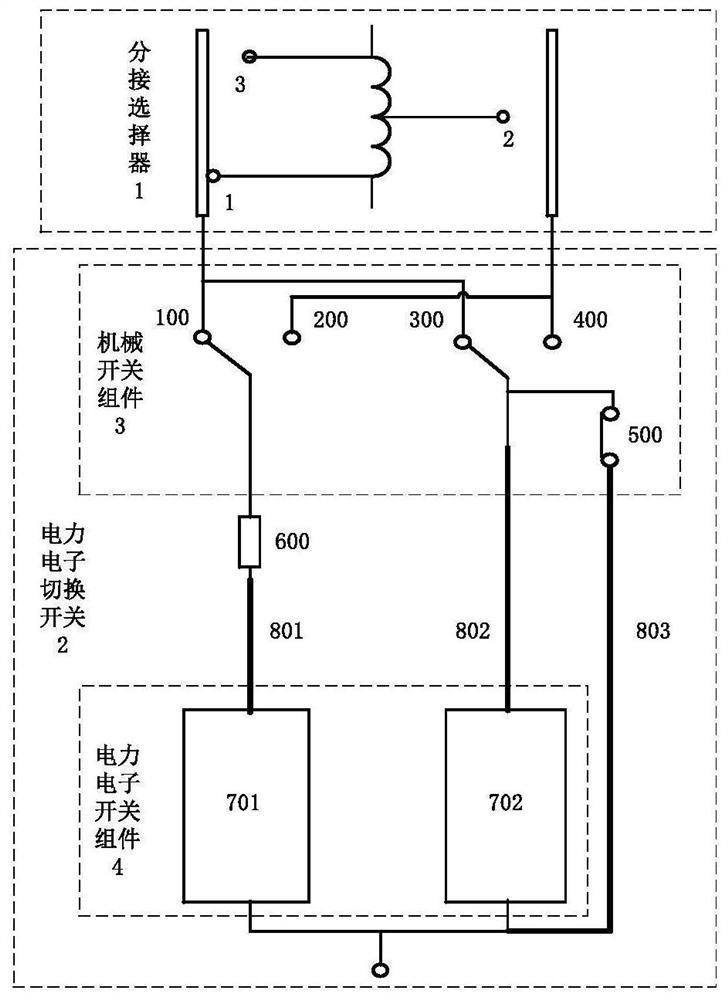

[0056] Embodiment 1 of the present invention provides an on-load tap changer for high-voltage transmission transformers, such as figure 1 As shown, it includes a tap selector 1 and a power electronic switch 2; the power electronic switch 2 includes a mechanical switch assembly 3, a power electronic switch assembly 4 and an insulating bushing;

[0057] The mechanical switch assembly 3 is connected to the winding taps of the high-voltage transmission transformer through the tap selector 1, the mechanical switch assembly 3 is connected to the power electronic switch assembly 4 through the insulating bushing, and both the mechanical switch assembly 3 and the power electronic switch assembly 4 are connected to the load branch The neutral point of the switch is connected, and the tap selector 1 and the mechanical switch assembly 3 are located inside the high-voltage transmission transformer, and the power electronic switch assembly 4 is located outside the high-voltage transmission t...

Embodiment 2

[0085] Embodiment 2 of the present invention provides a control method for an on-load tap changer of a high-voltage transmission transformer, and the specific flow chart is as follows Figure 11 As shown, the specific process is as follows:

[0086] S101: before the on-load tap changer is switched, control the mechanical switch assembly 3 of the power electronic transfer switch 2, so that the current flows through the high-voltage transmission transformer winding, one end of the tap selector 1, the mechanical switch assembly 3, the insulating bushing and the Neutral point of on-load tap-changer;

[0087] S102: During the switching of the on-load tap changer, adjust the state of the mechanical switch component 3, and trigger the power electronic switch component 4 of the power electronic switch 2 at the same time, so that the current flows through the winding of the high-voltage transmission transformer and the other part of the tap selector 1 in sequence One end, mechanical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com