High-stability phenol-yellowing-resistant silicone oil softener and preparation method thereof

A technology of softener and phenol yellowing, which is applied in the field of highly stable anti-phenol yellowing silicone oil softener and its preparation, and can solve the problems of large phenol yellowing, poor compatibility of softener components and anti-phenol yellowing agents, etc. , to achieve good acid resistance, stable and feasible preparation method, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a preparation method of the anti-phenol yellowing silicone oil softener, comprising the following steps:

[0046] (1) mix the silicone oil, emulsifier and solvent of formula amount, stir to obtain the first crude oil;

[0047] (2) adding co-emulsifier and partial deionized water to the first crude oil obtained in step (1), and stirring to obtain the second crude oil;

[0048] (3) adding the remaining deionized water to the second crude oil described in step (2) for several times, and stirring to obtain the third crude oil;

[0049] (4) Add anti-phenol yellowing agent to the third crude oil, and stir evenly to obtain the softener.

[0050] In some embodiments, the stirring temperature is 40~60℃, preferably 45~55℃; the stirring time is 30~60min; the stirring speed is 200~1500rpm, preferably 300~1000rpm, more preferably It is 400~700rpm.

[0051] In some embodiments, the formula amount of silicone oil, emulsifier and solvent is added ...

Embodiment 1

[0078] Step 1. Select DMC, N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane and MDM capping agent to synthesize amino silicone oil, the indicator is the solid content of 95% and the viscosity of 2500mPa·s , the amine value is 0.33 mmol / g.

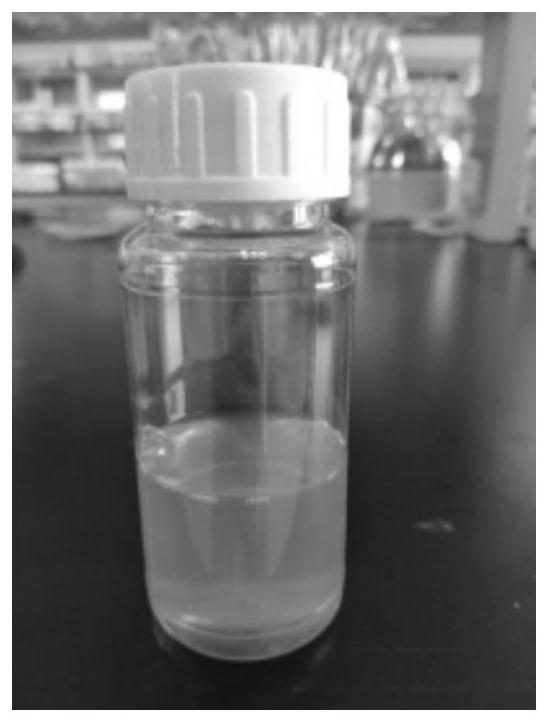

[0079] Step 2. 50g amino silicone oil synthesized in step 1, 10g isotridecanol polyoxyethylene ether (n=3), 10g isotridecanol polyoxyethylene ether (n=15), 15g diethylene glycol Butyl ether was added to the stirrer, stirred in a water bath at 50°C for 30min, and the speed was 500rpm; then 1g of hydrochloric acid and 20g of deionized water were added, and the mixture was stirred at 50°C for 30min and the speed was 500rpm; then 50g of deionized water was added, and the mixture was stirred at 50°C for 30min. The rotating speed is 500rpm; 100g of water is added at last; 2g of 3-hydroxypropionic acid is added at last to obtain the softener emulsion.

[0080] The softening agent obtained in this example was tested, and the phenolic yellowing ...

Embodiment 2

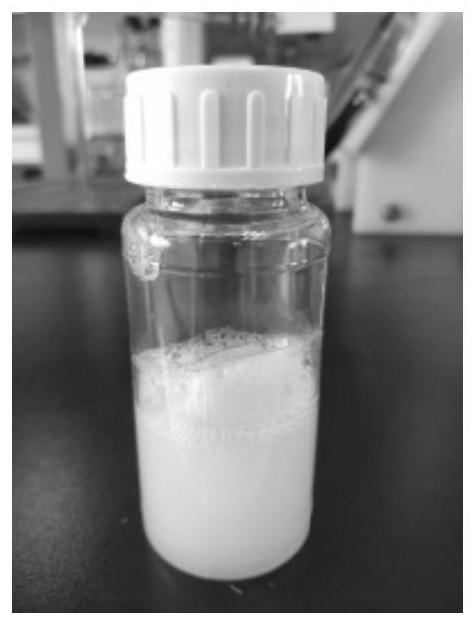

[0082] Step 1. Select linear body, cyclohexylaminopropyl methyldimethoxysilane and MM capping agent to synthesize amino silicone oil, the index is 95% solid content, the viscosity is 4000mPa·s, and the amine value is 0.45mmol / g.

[0083] Step 2. Add 50 g of amino silicone oil synthesized in step 1, 10 g of fatty alcohol polyoxyethylene ether (n=6), 10 g of fatty alcohol polyoxyethylene ether (n=9), and 12 g of isopropanol into a stirrer, at 55° C. Stir in a water bath for 60min, rotating speed 700rpm; then add 1.2g hydrochloric acid, 20g deionized water, stir at 55℃ for 60min, rotating speed 700rpm; add 50g deionized water, stir at 55℃ for 60min, rotating speed 700rpm; continue to add 110g deionized water, 5℃ Stir for 60min, rotating speed 700rpm; finally add 1.5g sulfuric acid to obtain softener emulsion.

[0084] The softener obtained in this example is tested, and the phenolic yellowing grade of polyester is grade 5, the hand feeling is 4.3 points, it is stable for 45 days ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com