Recycling method for activated carbon-based desulfurizer

A desulfurizer, activated carbon technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Human body and environmental hazards, etc., to achieve good practical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

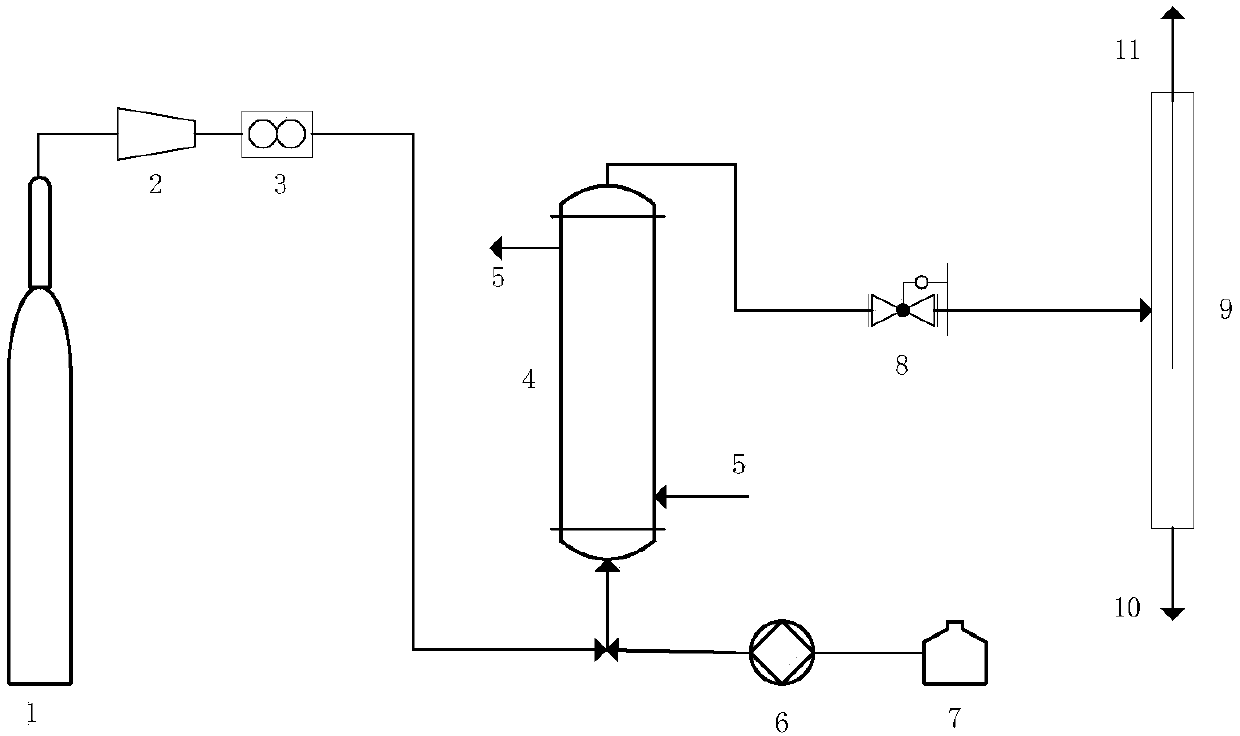

Method used

Image

Examples

Embodiment 1

[0041] (1) Dry the modified activated carbon desulfurizer in the desulfurization tank, the drying conditions are: air atmosphere of the desulfurization tank, the temperature is 50 ° C, and the drying time is 12 hours;

[0042] (2) adding the desulfurizing agent (sulfur content is 34wt%) in the step (1) to the catalytic cracking diesel oil whose flow rate is 260-280°C at 80°C, mechanically stirring for 6 hours, and then separating the solid and liquid to obtain the desulfurizing agent material;

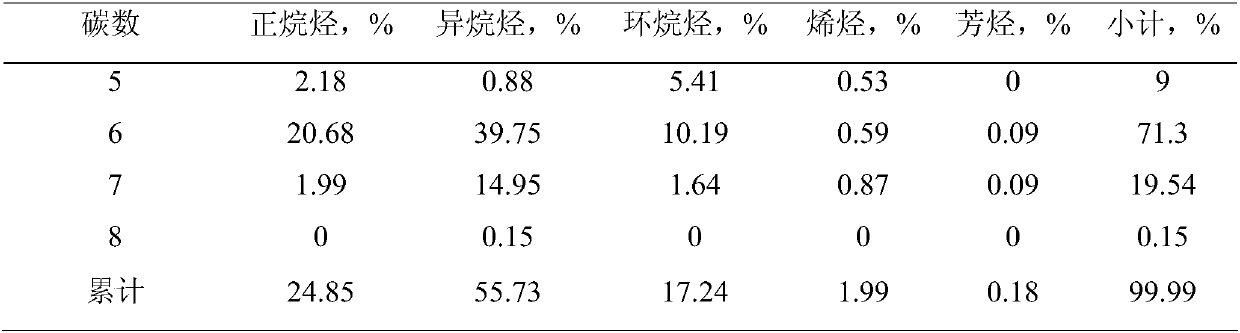

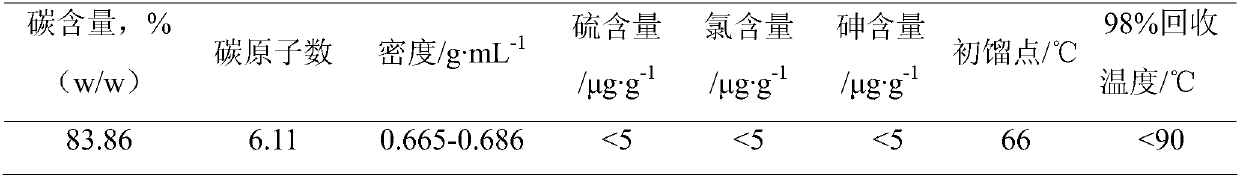

[0043] (3) Add the desulfurizing agent material in step (2) to No. 6 solvent oil, and obtain the treated desulfurizing agent activated carbon material after stirring for 1 h, wherein the sulfur content is 2.3wt%;

[0044] (4) Grind the activated carbon material in step (3) to ≤160 mesh, and use conventional methods to prepare composite oxide carriers with alumina, titanium oxide, and activated carbon as raw materials. The pore volume of the carrier is 0.52mL / g, and the specific surface ...

Embodiment 2

[0048] (1) In the desulfurization tank, the activated carbon loaded nickel desulfurizer (calculated as NiO, the nickel content is 17% of the catalyst) is dried, the drying conditions are: desulfurization tank 20% air+80% nitrogen atmosphere, the temperature is 60-80 ℃, drying time 10h;

[0049] (2) adding the desulfurizing agent (with a sulfur content of 28wt%) in the step (1) to the catalytic cracking diesel oil whose process flow is 280-300°C at 100°C, mechanically stirring for 8 hours, and then separating the solid and liquid to obtain the desulfurizing agent material;

[0050] (3) Add the desulfurizing agent material in step (2) to No. 6 solvent oil, and obtain the treated desulfurizing agent activated carbon material after stirring for 0.5h, wherein the sulfur content is 3.7wt%;

[0051] (4) Grind the activated carbon material in step (3) to ≤160 mesh, and use conventional methods to prepare composite oxide carriers with alumina, titanium oxide and activated carbon as raw...

Embodiment 3

[0055] (1) In the desulfurization tank, nickel and cobalt desulfurizers are loaded on activated carbon (in terms of NiO, the nickel content is 11% of the catalyst, and in terms of CoO 2 Calculated, the cobalt content is 9% of the catalyst,) for drying treatment, the drying conditions are: desulfurization tank 20% air + 80% nitrogen atmosphere, the temperature is 60-80 ℃, and the drying time is 10h;

[0056] (2) adding the desulfurizing agent (with a sulfur content of 28wt%) in the step (1) to the catalytic cracking diesel oil whose process flow is 280-300°C at 100°C, mechanically stirring for 8 hours, and then separating the solid and liquid to obtain the desulfurizing agent material;

[0057] (3) Add the desulfurizing agent material in step (2) to No. 6 solvent oil, and obtain the treated desulfurizing agent activated carbon material after stirring for 0.5h, wherein the sulfur content is 3.7wt%;

[0058] (4) Grind the activated carbon material in step (3) to ≤160 mesh, and us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com