Blue-light-curing photosensitive resin suitable for three-dimensional printing and preparation method thereof

A photosensitive resin and three-dimensional printing technology, applied in the direction of additive processing, etc., can solve the problems of slow curing speed, high viscosity of light-cured materials, large shrinkage rate, etc., to achieve the maintenance of product shape, low volume shrinkage rate, and avoid safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

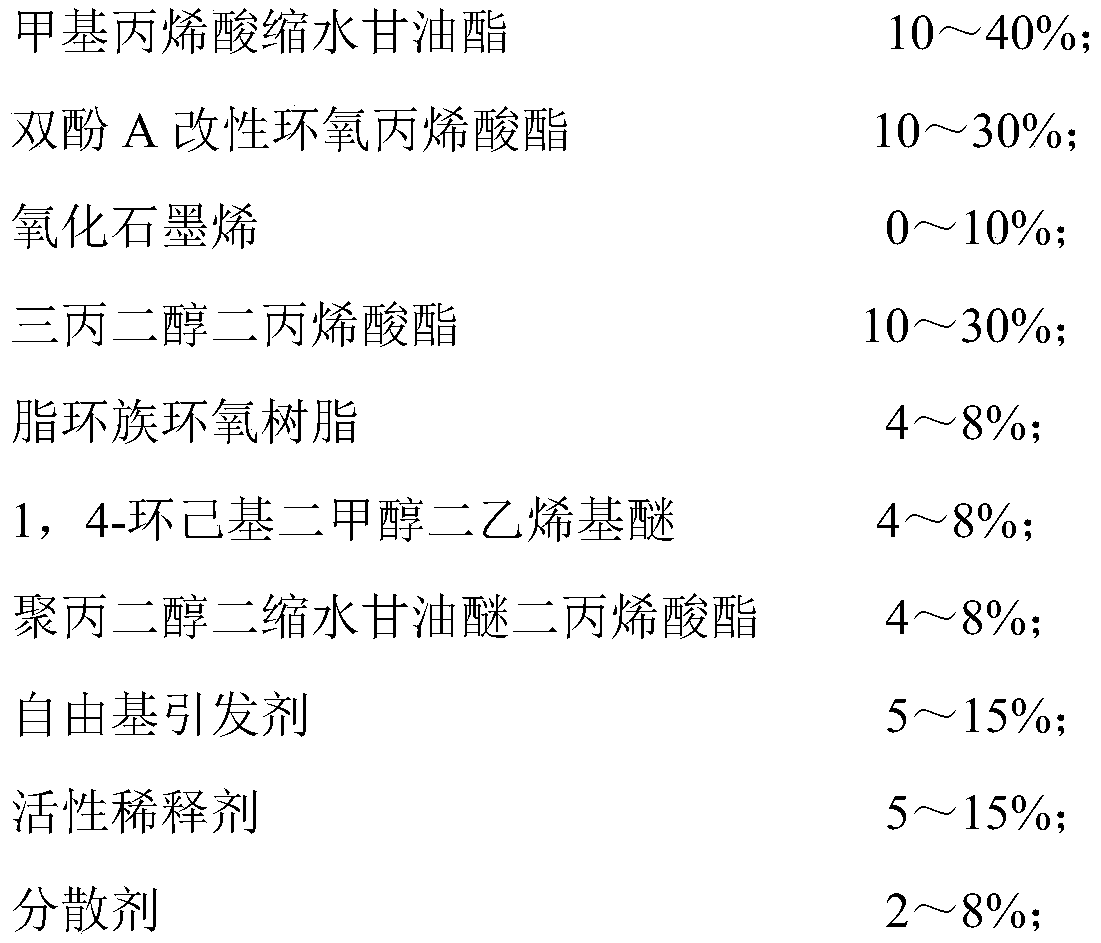

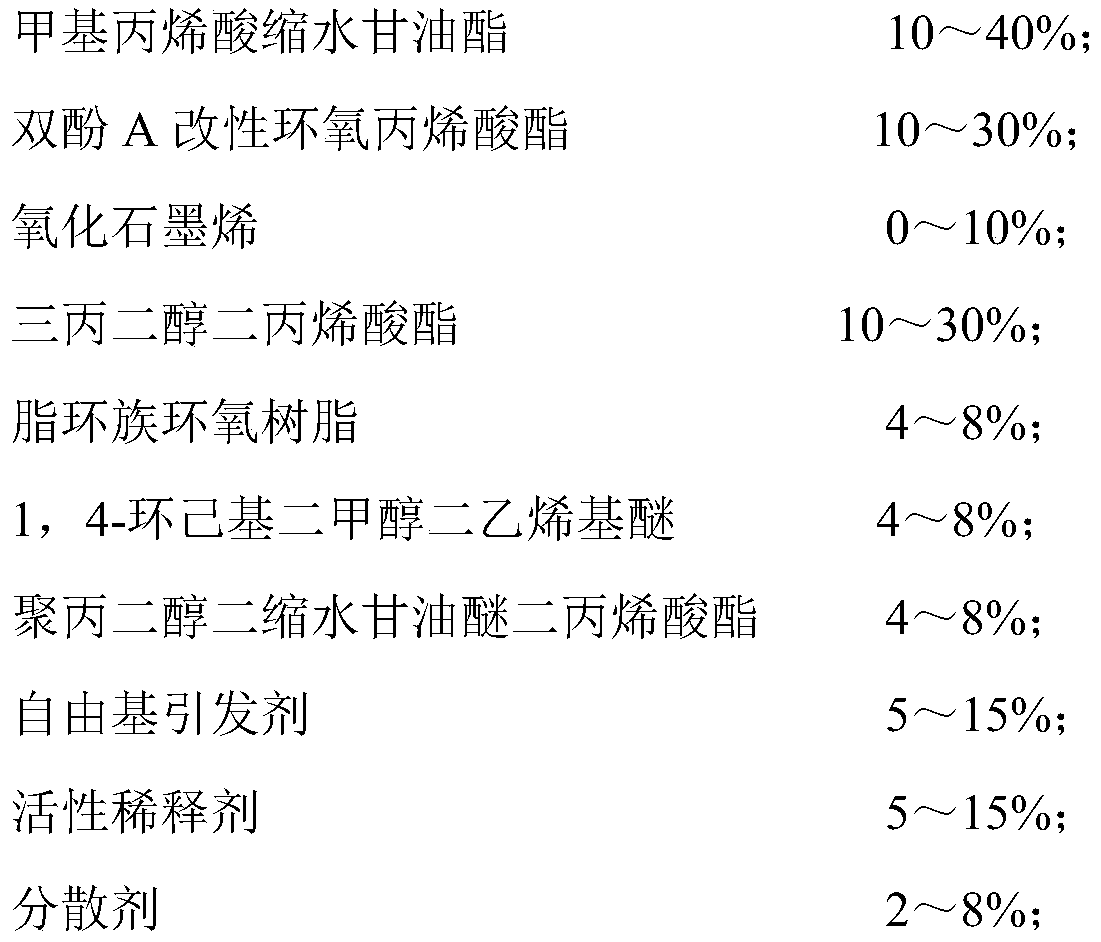

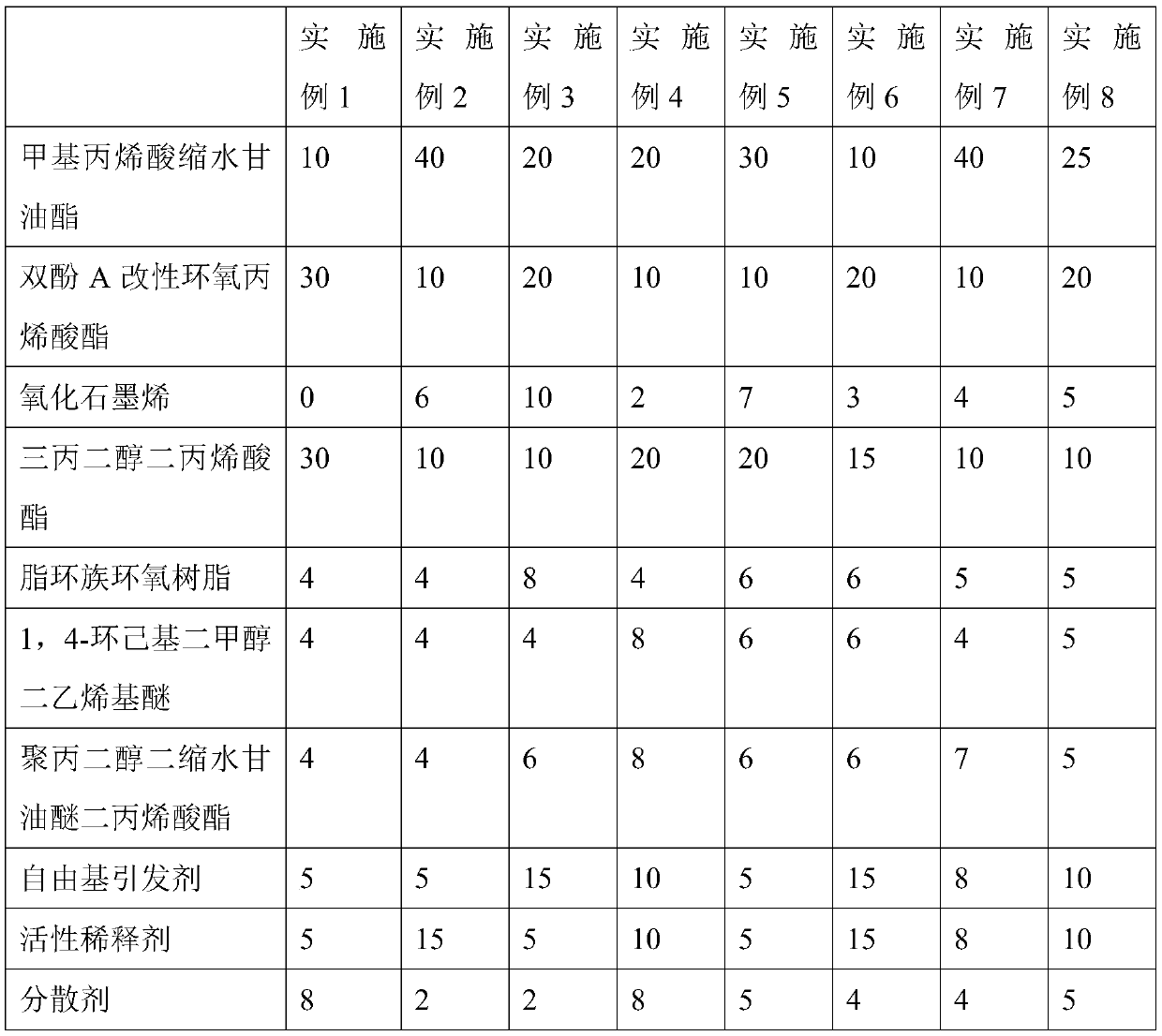

[0044] This embodiment provides a photosensitive resin for three-dimensional printing, the components and mass percentages are: 10wt.% glycidyl methacrylate, 30wt.% bisphenol A modified epoxy acrylate, 30wt.% Tripropylene glycol diacrylate, 4wt.% cycloaliphatic epoxy resin, 4wt.% 1,4-cyclohexyldimethanol divinyl ether, 4wt.% polypropylene glycol diglycidyl ether diacrylate, 5wt. % Free radical initiator, 5wt.% reactive diluent, 8wt.% dispersant.

[0045] Preparation:

[0046] A. Add glycidyl methacrylate, bisphenol A modified epoxy acrylate, tripropylene glycol diacrylate, and cycloaliphatic epoxy into the reactor equipped with a stirrer, thermometer, condenser and feeding tank. Resin, 1,4-cyclohexyl dimethanol divinyl ether, polypropylene glycol diglycidyl ether diacrylate and reactive diluent, stir evenly for 20 minutes;

[0047] B. In the reaction kettle, add dispersant and stir evenly for 20 minutes;

[0048] C. Add a free radical initiator to the reaction kettle. The temperatur...

Embodiment 2

[0051] This embodiment provides a photosensitive resin for three-dimensional printing, the components and mass percentages are: 40wt.% glycidyl methacrylate, 10wt.% bisphenol A modified epoxy acrylate, 6wt.% Graphene oxide, 10wt.% tripropylene glycol diacrylate, 4wt.% cycloaliphatic epoxy resin, 4wt.% 1,4-cyclohexyldimethanol divinyl ether, 4wt.% polypropylene glycol dicondensation Glyceryl ether diacrylate, 5wt.% free radical initiator, 15wt.% reactive diluent, 2wt.% dispersant.

[0052] Preparation:

[0053] A. Add glycidyl methacrylate, bisphenol A modified epoxy acrylate, tripropylene glycol diacrylate, and cycloaliphatic epoxy into the reactor equipped with a stirrer, thermometer, condenser and feeding tank. Resin, 1,4-cyclohexyl dimethanol divinyl ether, polypropylene glycol diglycidyl ether diacrylate and reactive diluent, stir evenly for 50 minutes, and inject graphene oxide while mixing;

[0054] B. Add dispersant to the reaction kettle and stir evenly for 60 minutes;

[00...

Embodiment 3

[0058] This embodiment provides a photosensitive resin for three-dimensional printing, the composition and mass percentage of which are: 20wt.% glycidyl methacrylate, 20wt.% bisphenol A modified epoxy acrylate, 10wt.% Graphene oxide, 10wt.% tripropylene glycol diacrylate, 8wt.% cycloaliphatic epoxy resin, 4wt.% 1,4-cyclohexyldimethanol divinyl ether, 6wt.% polypropylene glycol dihydrate Glyceryl ether diacrylate, 15wt.% free radical initiator, 5wt.% reactive diluent, 2wt.% dispersant.

[0059] Preparation:

[0060] A. Add glycidyl methacrylate, bisphenol A modified epoxy acrylate, tripropylene glycol diacrylate, and cycloaliphatic epoxy into the reactor equipped with a stirrer, thermometer, condenser and feeding tank. Resin, 1,4-cyclohexyl dimethanol divinyl ether, polypropylene glycol diglycidyl ether diacrylate and reactive diluent, stir evenly for 30 minutes, and inject graphene oxide while mixing;

[0061] B. In the reaction kettle, add dispersant and stir evenly for 40 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com