Polylactic acid/polycarbonate alloy material for 3D printing and preparation method thereof

A polycarbonate, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of limited compatibilization effect and large viscosity difference, achieve the effects of enriching varieties, promoting two-phase compatibility, and reducing volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

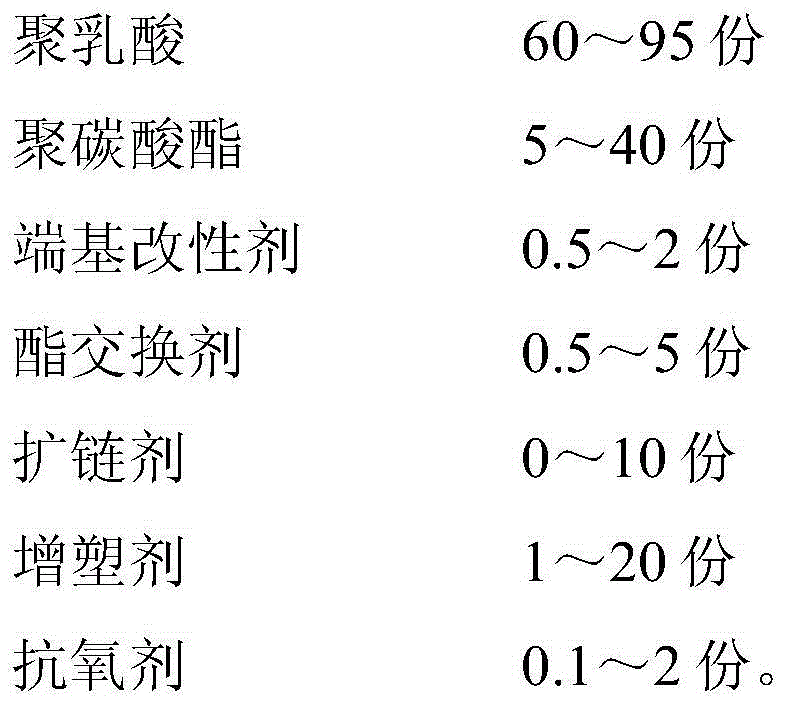

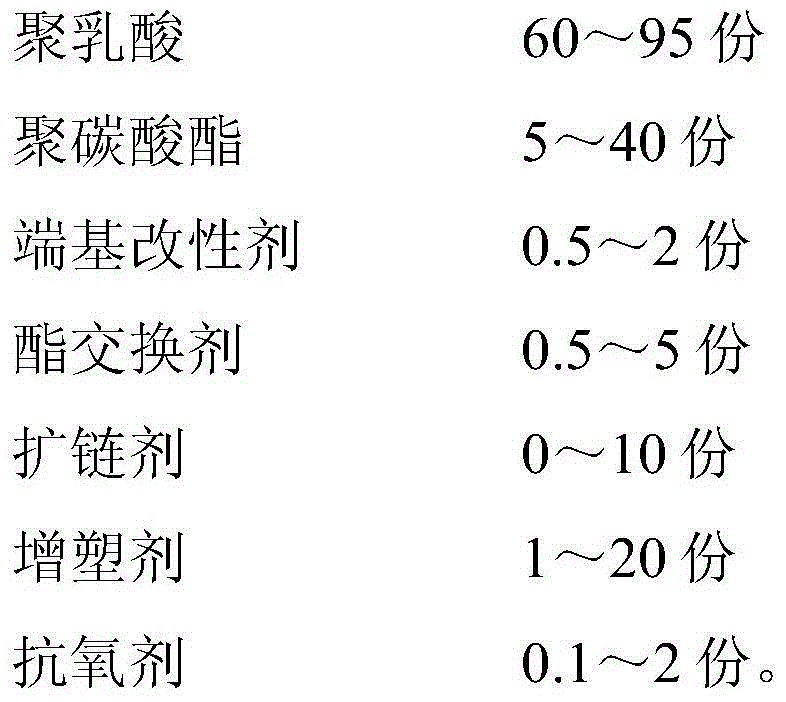

Method used

Image

Examples

Embodiment 1

[0040] 1) 80 parts by weight of polylactic acid (poly-L-type lactic acid), 20 parts by weight of polycarbonate, 1.2 parts by weight of 2,6-dihydroxybenzoic acid, and 1.5 parts by weight of tetrabutyl titanate in a high-speed mixer (high-speed mixer The rotating speed is 750r / min) and mixed for 8 minutes. After mixing evenly, the mixture is obtained; the mixture is extruded in a twin-screw extruder, pelletized, and dried (the drying temperature of the pellets is 80°C) to the moisture content If it is lower than 0.3%, pellets are obtained; the screw speed of the twin-screw extruder is 400r / min; °C, 225 °C.

[0041] 2) all above-mentioned pellets and 0.8 weight part p-toluene diisocyanate, 3 weight parts tributyl citrate and 1.5 weight part phenyl salicylate, 0.3 weight part antioxidant 1010 in high-speed mixer (high-speed mixer The rotation speed is 750r / min) and mixed for 5 minutes, and after mixing evenly, the mixture is obtained; the mixture is extruded and drawn in a twin-s...

Embodiment 2

[0044] 1) 70 parts by weight of polylactic acid (poly-L-type lactic acid), 30 parts by weight of polycarbonate, 0.9 parts by weight of 3-aminoisoxazole, and 1.5 parts by weight of isobutyl titanate in a high-speed mixer (the speed of the high-speed mixer 750r / min) and mixed for 8 minutes, after mixing evenly, the mixture was obtained; the mixture was extruded in a twin-screw extruder, granulated, and dried (drying temperature was 80°C) until the moisture content was lower than 0.3%. The pellets were obtained; the screw speed of the twin-screw extruder was 300r / min; the temperature settings of zone I, zone II, zone III and zone IV of the extruder were: 205°C, 220°C, 235°C, 230°C.

[0045] 2) All above-mentioned pellets and 2 parts by weight of resorcinol diglycidyl ether, 2 parts by weight of 9,10-epoxy octyl stearate and 2.5 parts by weight of butyl benzoate, 0.2 parts by weight of antioxidant 1010 in Mix in a high-speed mixer (the speed of the high-speed mixer is 750r / min) fo...

Embodiment 3

[0048] 1) 60 parts by weight of polylactic acid (poly-L-type lactic acid), 40 parts by weight of polycarbonate, 0.7 parts by weight of 2-thiophene acetyl chloride, and 1 part by weight of tetrabutyl titanate in a high-speed mixer (the rotating speed of the high-speed mixer is 750r / min) for 8 minutes, after mixing evenly, put the mixture in a twin-screw extruder to extrude, make material, dry (the drying temperature is 80°C) until the moisture content is lower than 0.3%, and obtain pellets ; wherein the screw speed of the twin-screw extruder is 500r / min; the temperature settings of the extruder I, II, III, and IV are: 205°C, 220°C, 235°C, 230°C.

[0049] 2) All the above-mentioned pellets and 1.5 parts by weight of diphenylmethane diisocyanate, 4 parts by weight of octyl soyate and 3 parts by weight of phenyl salicylate, 0.3 parts by weight of antioxidant 168 in a high-speed mixer (high-speed The rotation speed of the mixer is 750r / min) and mixed for 5 minutes, and after mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com