Composite dental restoration resin with silica microspheres as filler and preparation method thereof

A technology of silica and composite resin, applied in dental preparations, dentistry, medical science, etc., can solve the problems of low strength of composite resin, high curing shrinkage rate, and difficulty in uniform dispersion, etc., and achieve excellent physical and mechanical properties, dispersion Good performance and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The components of the composite resin and the content of each component are:

[0038] components

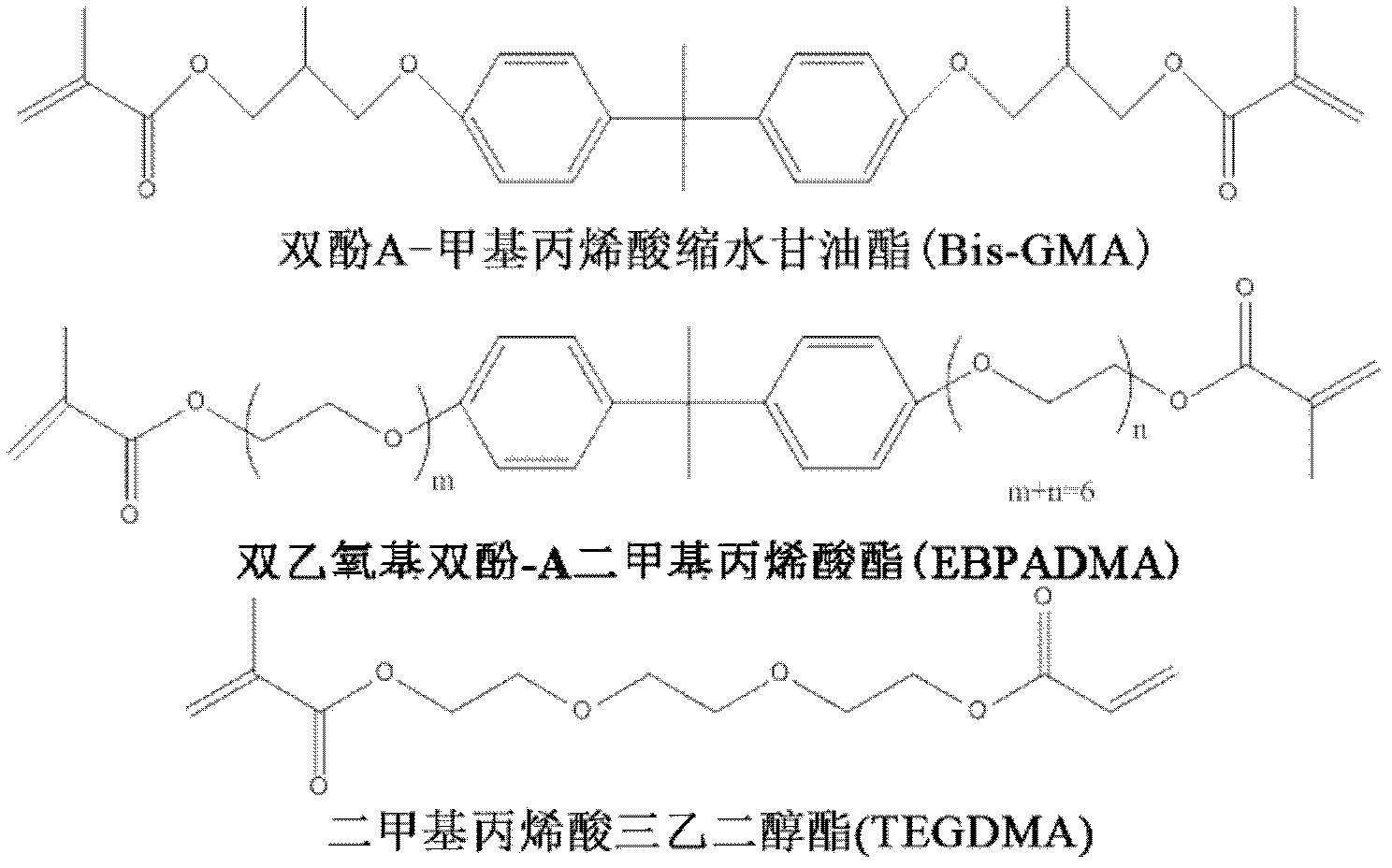

Bis-GMA

14.35

TEGDMA

14.35

CQ

0.06

4-EDMAB

0.24

Modified SiO 2 Microspheres

71

[0039] (1) The specific steps for the preparation of silica microspheres are as follows:

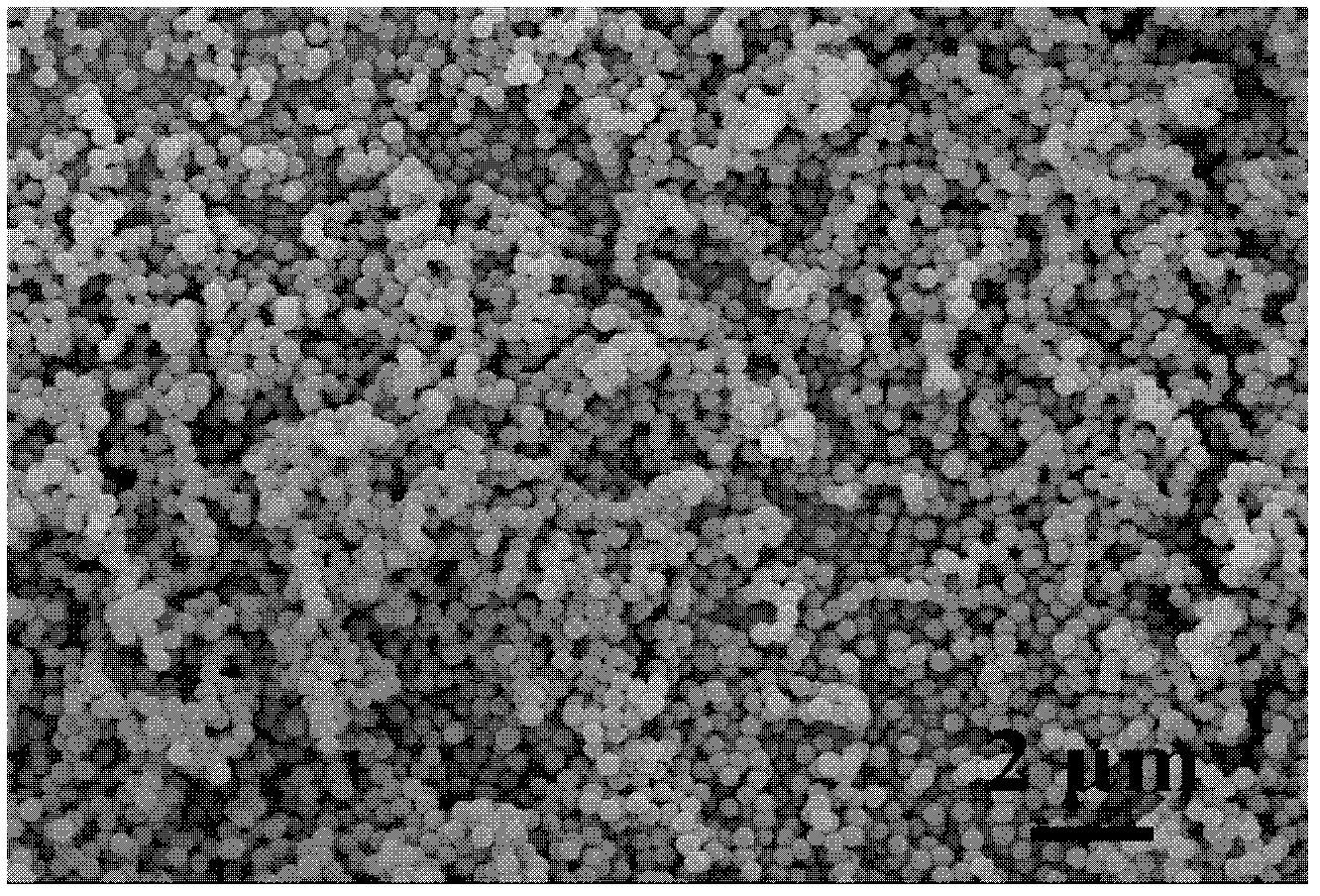

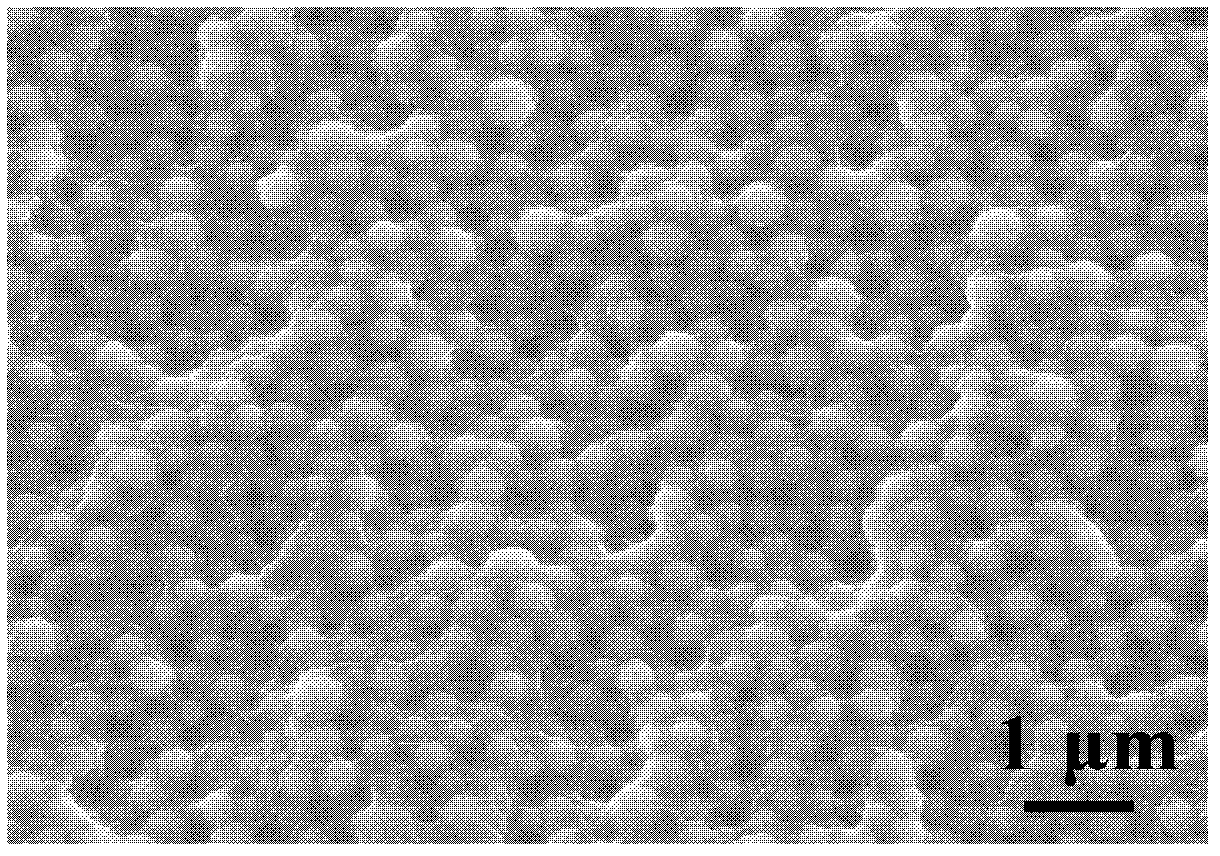

[0040]Measure 225mL of absolute ethanol, 150mL of ammonia water, and 30mL of ultrapure water in a three-neck flask, mix them evenly, then add 17.5mL of tetraethylorthosilicate TEOS, stir at 60±5°C for 2 hours, and wash the obtained solution with distilled water until neutral. Then wash with absolute ethanol 2 to 3 times, dry in vacuum at 110°C for 24 hours, and grind; modified SiO 2 The method is, the SiO after the above treatment 2 , γ-methacryloxypropyltrimethoxysilane (γ-MPS), cyclohexane and n-propylamine were mixed and stirred at 25±5°C for 30-40min; then heated to 60±5°C and stirred for 30-40min; t...

Embodiment 2

[0044] The components of the composite resin and the content of each component are:

[0045] components

Bis-GMA

20.09

TEGDMA

8.61

CQ

0.06

4-EDMAB

0.24

Modified SiO 2 Microspheres

71

[0046] (1) The specific steps for the preparation of silica microspheres are as follows:

[0047] Measure 225mL of absolute ethanol, 150mL of ammonia water, and 30mL of ultrapure water in a three-neck flask, mix them evenly, then add 17.5mL of tetraethylorthosilicate TEOS, stir at 60±5°C for 2 hours, and wash the obtained solution with distilled water until neutral. Then wash with absolute ethanol 2 to 3 times, dry in vacuum at 110°C for 24 hours, and grind; modified SiO 2 The method is, the SiO after the above treatment 2 , γ-methacryloxypropyltrimethoxysilane (γ-MPS), cyclohexane and n-propylamine were mixed and stirred at 25±5°C for 30-40min; then heated to 60±5°C and stirred for 30-40min; t...

Embodiment 3

[0051] The components of the composite resin and the content of each component are:

[0052] components

EBPADMA

20.09

TEGDMA

8.61

CQ

0.06

4-EDMAB

0.24

Modified SiO 2 Microspheres

71

[0053] (1) The specific steps for the preparation of silica microspheres are as follows:

[0054] Measure 225mL of absolute ethanol, 150mL of ammonia water, and 30mL of ultrapure water in a three-neck flask, mix them evenly, then add 17.5mL of tetraethylorthosilicate TEOS, stir at 60±5°C for 2 hours, and wash the obtained solution with distilled water until neutral. Then wash with absolute ethanol 2 to 3 times, dry in vacuum at 110°C for 24 hours, and grind; modified SiO 2 The method is, the SiO after the above treatment 2 , γ-methacryloxypropyltrimethoxysilane (γ-MPS), cyclohexane and n-propylamine were mixed and stirred at 25±5°C for 30-40min; then heated to 60±5°C and stirred for 30-40min; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com