High-temperature-resistant photosensitive resin composition used for photocuring rapid formation

A photosensitive resin, high temperature resistant technology, applied in the field of polymer materials, can solve the problems of insufficient toughness and strength, small curing shrinkage, high water absorption, and achieve the effects of high dimensional stability, small volume shrinkage and fast reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

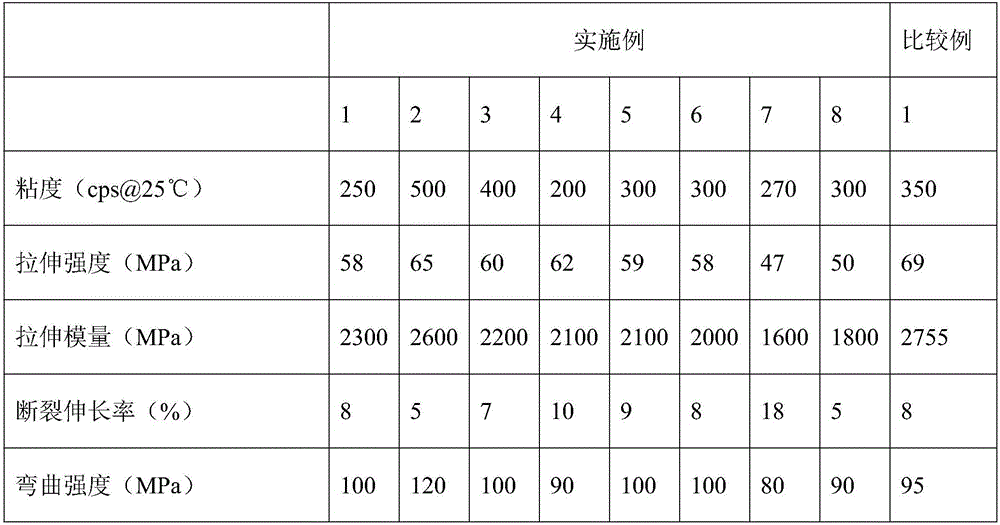

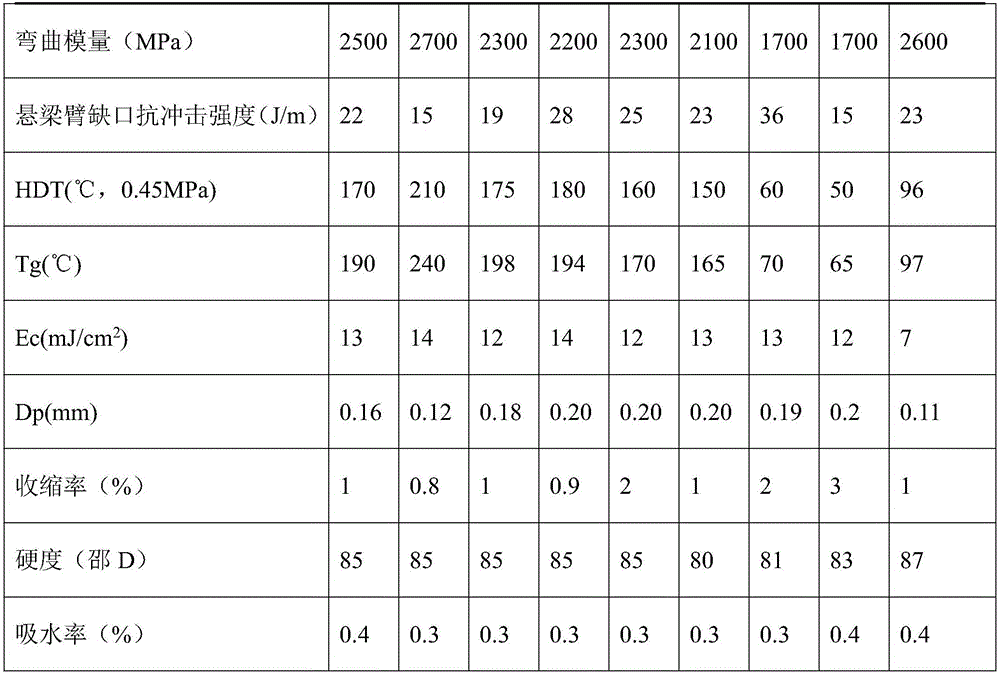

Examples

Embodiment 1

[0021] A high-temperature-resistant photosensitive resin composition for photocuring rapid prototyping, comprising the following components by weight:

[0022] 10 parts of tricyclopentyl dimethoxy type epoxy resin, 10 parts of phenolic novolac epoxy resin, 16 parts of 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate, 10 parts Trimethylolpropane triglycidyl ether, 15 parts tetrafunctional polyester acrylate, 10 parts dipentaerythritol hexaacrylate, 15 parts tricyclodecane dimethanol diacrylate, 3 parts nano silica, 5 parts acrylate Copolymer core-shell particles, 2.5 parts of hydroxycyclohexyl phenyl ketone, 3.5 parts of diphenyl-(4-phenylthio)phenylsulfonium hexafluoroantimonate.

Embodiment 2

[0024] A high-temperature-resistant photosensitive resin composition for photocuring rapid prototyping, comprising the following components by weight:

[0025] 10 parts of bisphenol A type epoxy resin, 16 parts of o-cresol novolac epoxy resin, 10 parts of 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate, 10 parts of resorcinol di Glycidyl ether, 15 parts o-cresol novolac epoxy acrylate, 15 parts 3(ethoxy)trimethylolpropane triacrylate, 10 parts tris(2-hydroxyethyl)isocyanurate triacrylate, 3 Parts of nano-silica, 5 parts of acrylate copolymer core-shell structure particles, 2.5 parts of hydroxycyclohexyl phenyl ketone, 3.5 parts of diphenyl-(4-phenylthio)phenylsulfonium hexafluoroantimonate.

Embodiment 3

[0027] A high temperature resistant photosensitive resin composition for photocuring rapid prototyping, comprising the following components by weight: 16 parts of bisphenol A epoxy resin, 10 parts of phenol novolac epoxy resin, 10 parts of trimethylol propane Glycidyl ether, 10 parts resorcinol diglycidyl ether, 15 parts bisphenol A epoxy acrylate, 15 parts trimethylolpropane triacrylate, 10 parts tris(2-hydroxyethyl)isocyanurate Acrylate, 3 parts of nano-silica, 5 parts of acrylate copolymer core-shell structure particles, 2.5 parts of hydroxycyclohexyl phenyl ketone, 3.5 parts of diphenyl-(4-phenylthio)phenylsulfonium hexafluoroantimony salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com