High-strength composite salt core material for low-melting-point alloy casting, salt core and preparation method

A technology for alloy casting and compound salt, which is applied in the field of salt core and preparation, and high-strength compound salt core material for low melting point alloy casting, can solve the problems of high salt core equipment requirements, difficult to mix uniformly, and low salt core strength, etc. Easy industrial application, simple preparation process, small volume shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

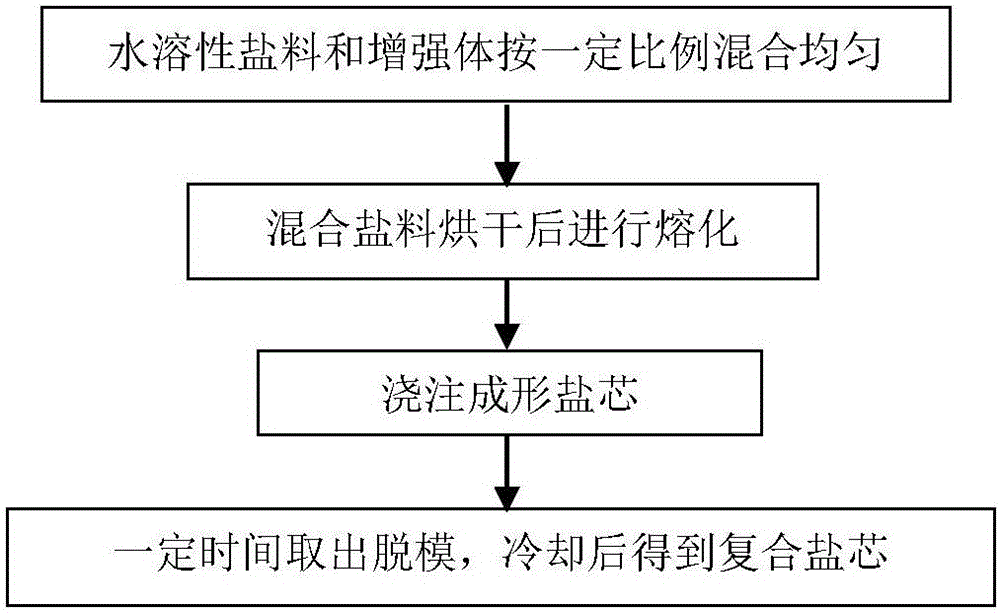

Method used

Image

Examples

Embodiment 1

[0034] Composite salt core material preparation: 100 parts by mass of water-soluble inorganic salt (80mol% KNO 3 + 20 mol% KCl).

[0035]Mix the weighed salt material evenly, dry it in a drying box at 110°C, cool to room temperature with the furnace, and then put it into a corundum crucible in a well-type resistance furnace to melt until the molten salt is completely melted to a temperature exceeding the selected When the water-soluble inorganic salt has a melting point of 15°C, it is poured into a metal mold with a preheating temperature of 150°C, demolded after 20 seconds, kept in a 130°C holding furnace for 2 hours, and then cooled to room temperature with the furnace to prepare a composite salt core.

[0036] By preparing a standard strip-shaped sample, its bending strength is measured to be 22MPa; in a constant humidity bottle with an ambient relative humidity of 98% to 99%, the 24h moisture absorption rate of the sample is about 0.568%; the volume shrinkage of the sample...

Embodiment 2

[0038] Composite salt core material preparation: 90 parts by mass of water-soluble inorganic salt (80mol% KNO 3 +20mol% KCl)+10 parts by mass of 200-mesh bentonite.

[0039] Mix the weighed salt material evenly, dry it in a drying box at 110°C, cool to room temperature with the furnace, and then put it into a corundum crucible in a well-type resistance furnace. After the molten salt is completely melted, stir it with alumina Stir the rod until it exceeds the melting point of the selected water-soluble inorganic salt by 25°C, stop stirring, pour it into a metal mold with a preheated temperature of 150°C, demould after 20 seconds, and keep it in a holding furnace at 135°C for 1.8 hours, then it is prepared. Composite salt core.

[0040] By preparing a standard strip sample, its bending strength is greater than 35MPa; in a constant humidity bottle with a relative humidity of 98% to 99%, the 24h moisture absorption rate of the sample is about 0.502%; the volume shrinkage of the s...

Embodiment 3

[0042] Composite salt core material preparation: 80 parts by mass of water-soluble inorganic salt (100mol% KNO 3 )+20 parts by mass of 400 mesh alumina powder.

[0043] Mix the weighed salt material evenly, dry it in a drying box at 105°C, cool to room temperature with the furnace, and then put it into a corundum crucible in a well-type resistance furnace. After the molten salt is completely melted, stir it with alumina Stir the rod until it exceeds the melting point of the selected water-soluble inorganic salt by 30°C, stop stirring, pour it into a metal mold with a preheated temperature of 130°C, demould it after 15 seconds, and keep it in a 140°C holding furnace for 1.5 hours, then it is prepared. Composite salt core.

[0044] By preparing a standard strip-shaped sample, its flexural strength is measured to be 28MPa; in a constant humidity bottle with a relative humidity of 98% to 99%, the 24h moisture absorption rate of the sample is about 0.303%; the volume shrinkage of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com