Preparation method for homogeneously-enhanced polyvinylidene fluoride hollow fiber membrane

A polyvinylidene fluoride, homogenous reinforcement technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of poor interface bonding strength, rupture of membrane filaments, and impact on effluent water quality, etc., to improve mechanical properties, interface Good bonding strength and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] According to the preparation method of the homogeneously reinforced membrane of the present invention, a homogeneously reinforced polyvinylidene fluoride hollow fiber membrane can be prepared. The homogeneous reinforced membrane has the characteristics of both melt-spinning and solution-spinning membranes, can significantly improve the hydrophilicity of the PVDF membrane, and at the same time improve the mechanical properties of the membrane.

[0030] What is not mentioned in the present invention is applicable to the prior art.

Embodiment 1

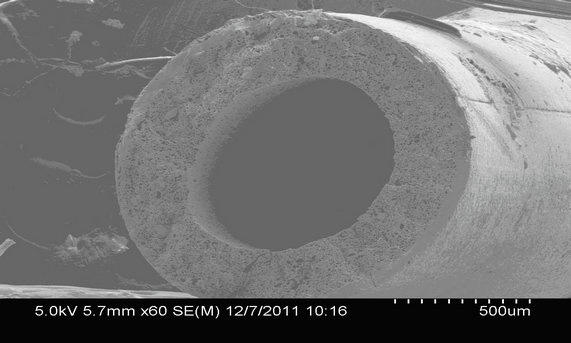

[0033] Preparation of base membrane: polyvinylidene fluoride hollow fiber membrane was prepared by melt spinning method, and it was used as reinforcement base membrane; the maximum pore size was 1.4 μm.

[0034] Prepare casting solution: mix 14% PVDF with 10% polyvinylpyrrolidone k30, dissolve in 76% dimethylacetamide solvent, stir at 70°C until completely dissolved, Degassing in a vacuum oven at 70°C to obtain a clear casting solution.

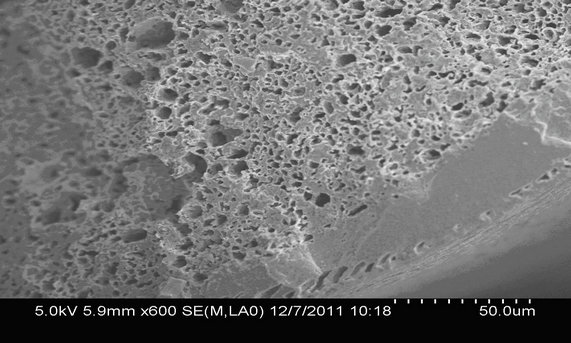

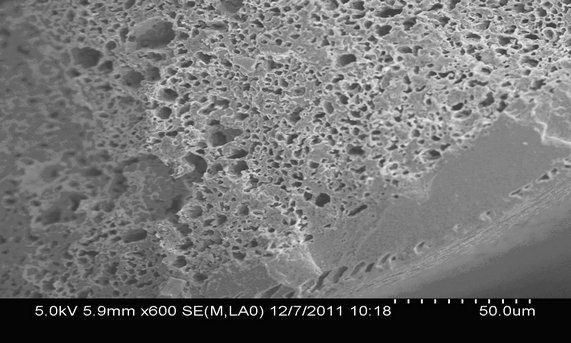

[0035] Preparation of homogeneous mold: First, the polyvinylidene fluoride casting solution is evenly coated on the surface of the reinforcement base film through the spinning spinneret, and then the coated base film is pulled by the godet roller at a speed of 10cm / min, spun into a film, and then immersed in an ultrafiltration water coagulation bath at room temperature through a 15cm long air gap. After 24 hours, it was solidified and formed into a homogeneous reinforced film.

[0036] Performance test: The pure water flux of the obtain...

Embodiment 2

[0038]Preparation of base membrane: polyvinylidene fluoride hollow fiber membrane was prepared by melt spinning method, and it was used as reinforcement base membrane; the maximum pore size was 2.2 μm.

[0039] Preparation of casting solution: mix 18% PVDF with 8% pore-forming agent (7% PEG 600; 3% Tween-80), dissolve in 74 % dimethylacetamide solvent, stirred at 70°C until completely dissolved, and degassed in a vacuum oven at 70°C to obtain a clear casting solution.

[0040] Preparation of homogeneous mold: First, the polyvinylidene fluoride casting solution is evenly coated on the surface of the reinforcement base film through the spinning spinneret, and then the coated base film is pulled by the godet roller at a speed of 25cm / min, spun into a film, and then immersed in an ultrafiltration water coagulation bath at 40°C through a 5cm long air gap. After 24 hours, it was solidified and formed into a homogeneous reinforced film.

[0041] Performance test: The pure water flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com