Membrane bioreactor having single header membrane module

a membrane bioreactor and membrane module technology, applied in the direction of membranes, filtration separation, separation processes, etc., can solve the problems of fibers at either end being plugged or fouled, corresponding decrease in the filtration capacity of the system, and inhibiting fiber movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

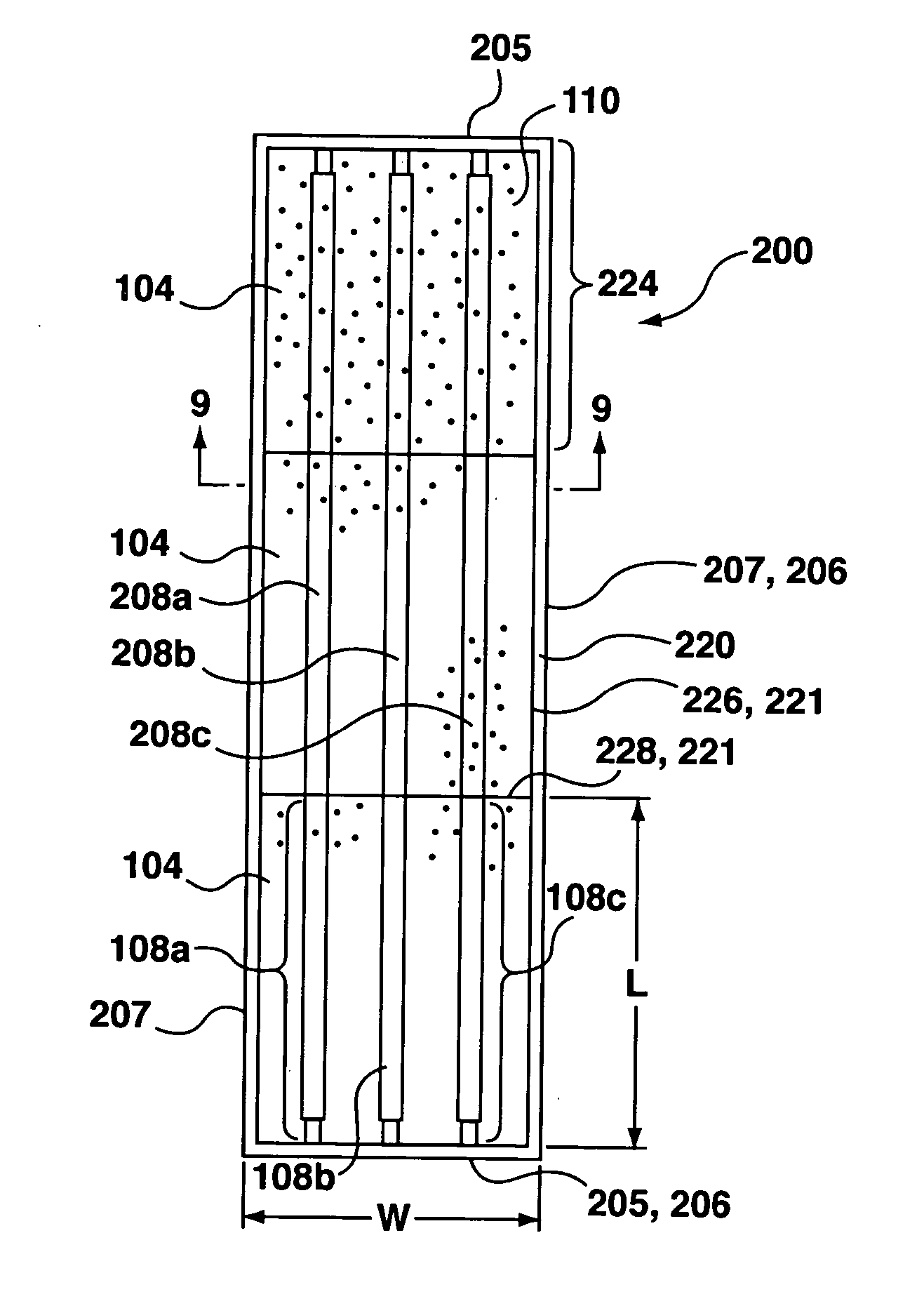

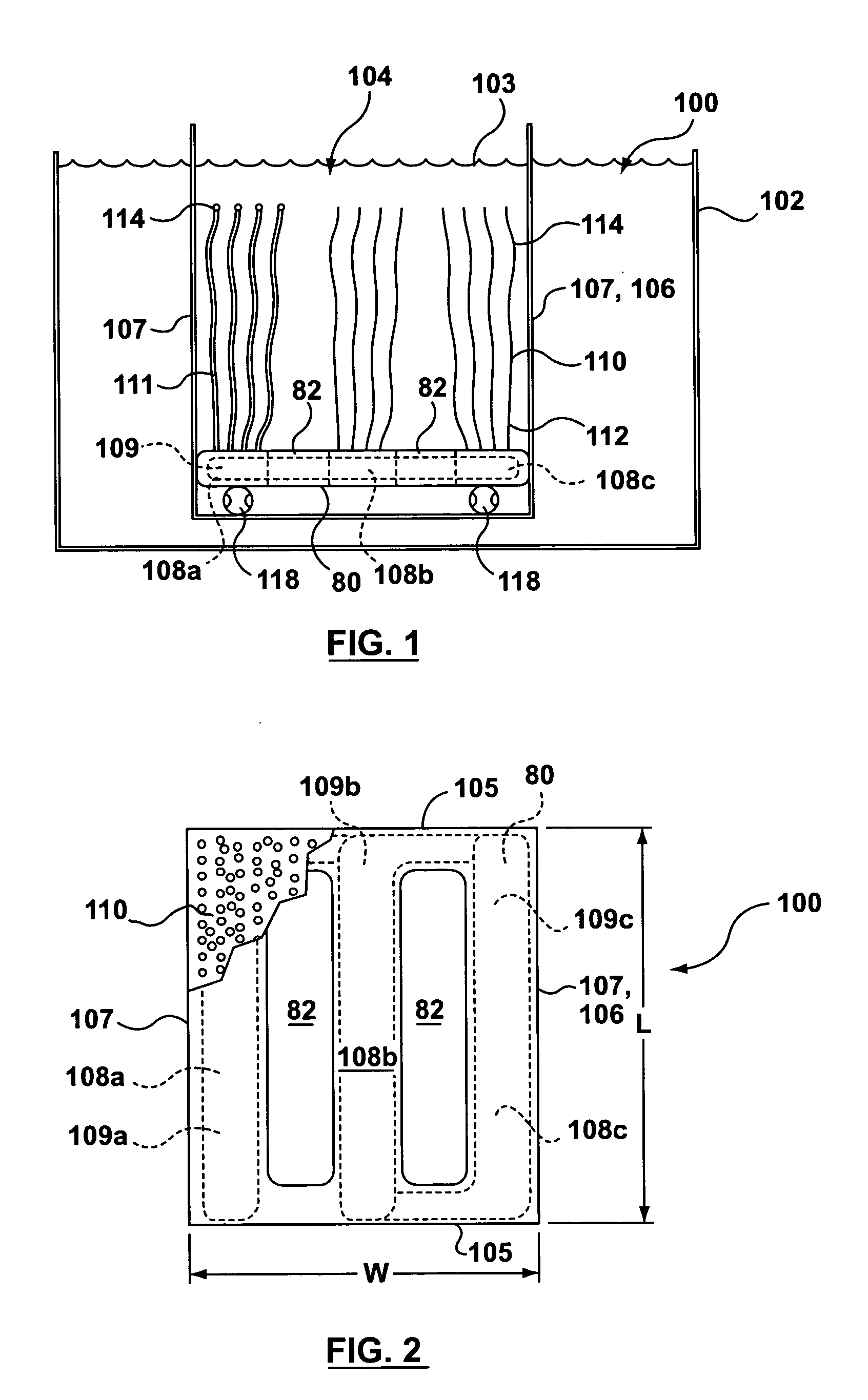

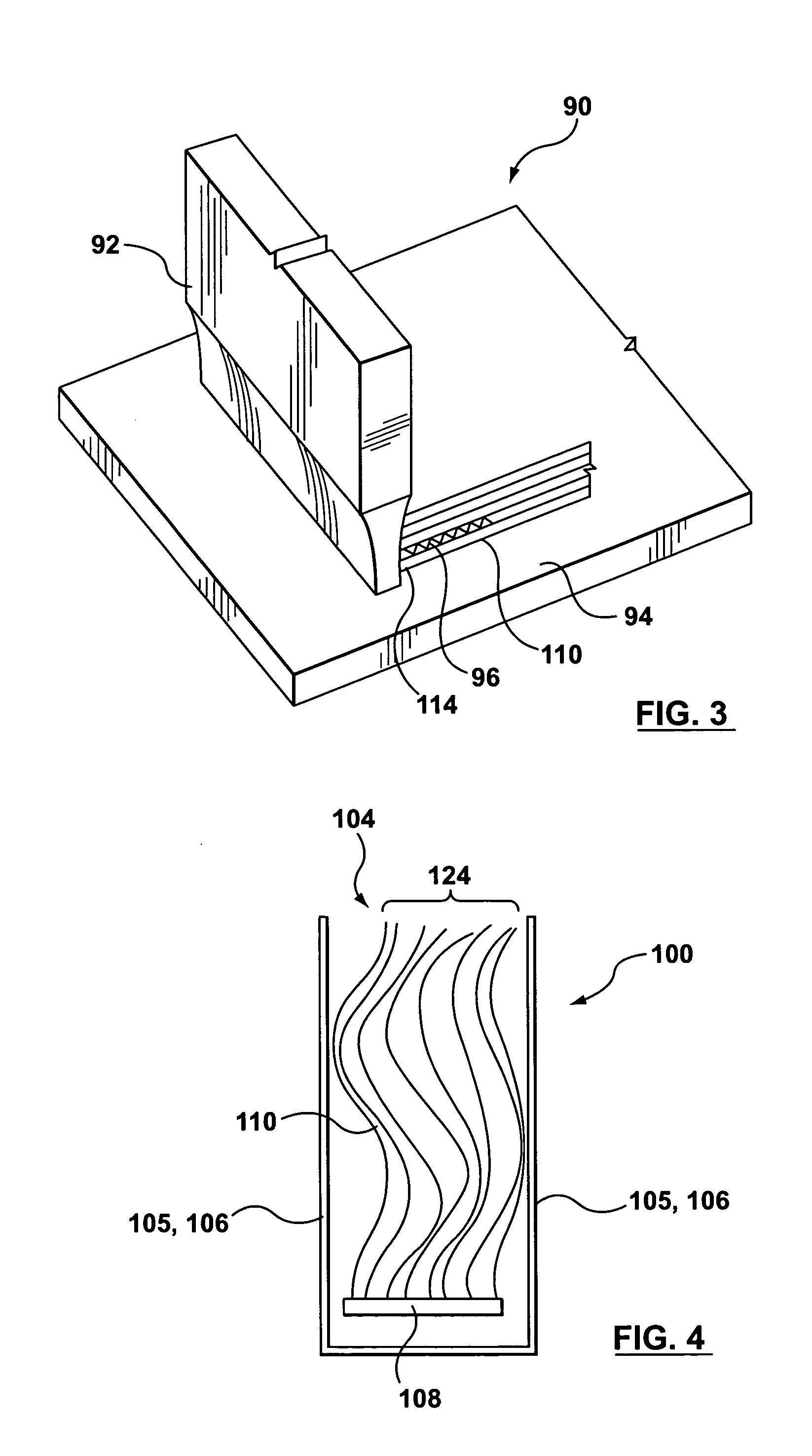

[0039] A filtration apparatus according to the present invention is shown generally at 100 in FIG. 1. In FIG. 1, the apparatus 100 is shown in combination with a tank 102 that contains liquid 103 from which filtered water (permeate) is to be withdrawn. The tank 102 may be part of a bioreactor, a drinking water filtration plant, or another type of solid / fluid separation system. In some applications, providing a tank 102 may not be required. For example, the apparatus 100 may be a self-contained unit holding liquid 103. Alternately, the apparatus 100 may be co-extensive with a tank or used in an apparatus and / or process as described in PCT Patent Application No. PCT / CA00 / 01354, published as WO 01 / 36075 which is incorporated herein in its entirety by this reference to it.

[0040] The apparatus 100 has a housing 106 with vertical side panels that define a filtration cell 104. More specifically, the housing 106 has opposed vertical end panels 105, and vertical side panels 107 extending be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com