PDMS/PVDF pervaporation composite membrane, preparation method and application thereof

A technology of pervaporation and composite membrane, which is applied in chemical instruments and methods, semi-permeable membrane separation, separation/purification of carboxylic acid compounds, etc., to achieve the effects of high permeation flux, good application prospect and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

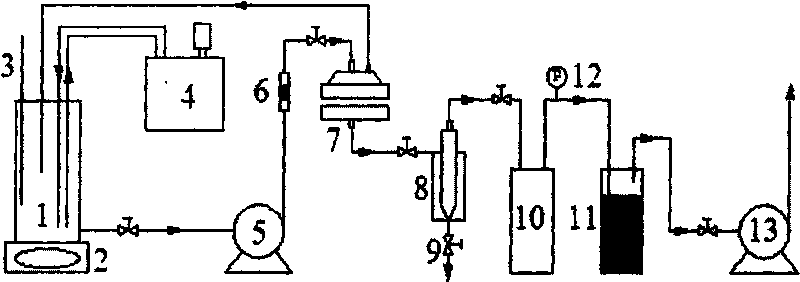

Method used

Image

Examples

Embodiment 1

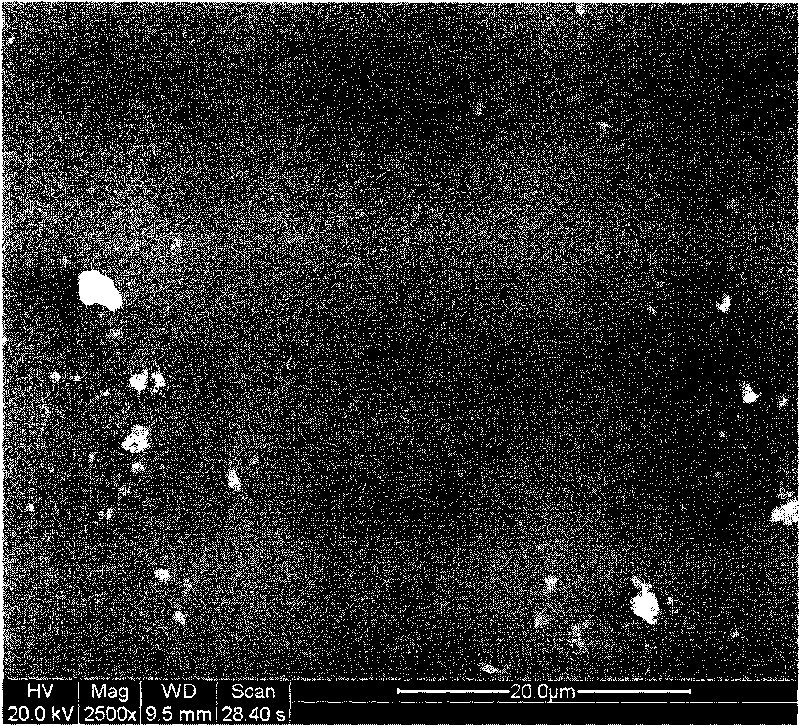

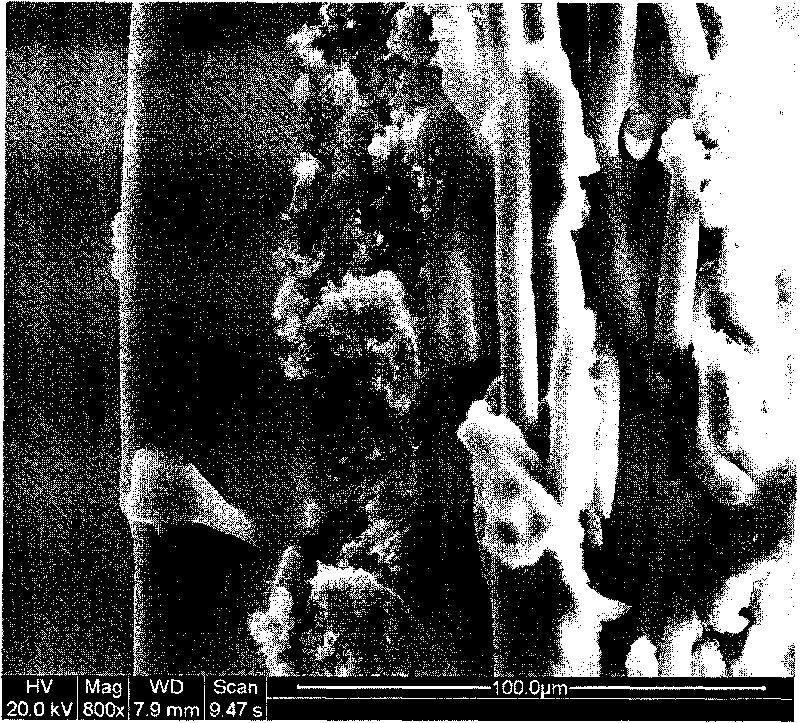

[0026] Example 1 Preparation of pervaporation composite membrane

[0027] Its preparation method is as follows: According to the required mass ratio, take 6 parts of polymer PDMS, 3 parts of solvent n-hexane, 0.4 part of crosslinking agent orthosilicate and 0.1 part of curing agent dibutyltin dilaurate, mix them, stir them evenly and Stand to defoam, pour it on the polyvinylidene fluoride microporous filter membrane with a pore size of 0.1 μm soaked in 20% polyethylene glycol aqueous solution for 24 hours, scrape it with a scraper to form a film, and let it stand at room temperature 24 hours to complete the cross-linking, and then soak the composite membrane in distilled water for 24 hours to dissolve the residual polyethylene glycol in the support layer. Finally, the composite membrane was dried under vacuum for 24 hours to obtain a PDMS / PVDF composite membrane with a total thickness of the composite membrane of 135 μm and a thickness of the skin separation layer of 35 μm.

Embodiment 2

[0028] Example 2 Preparation of pervaporation composite membrane

[0029] Its preparation method is as follows: according to the required mass ratio, take 6 parts of polymer PDMS, 4 parts of solvent n-hexane, 0.3 part of crosslinking agent tetraethyl orthosilicate and 0.2 part of curing agent dibutyltin dilaurate, mix, stir evenly and Stand to defoam, pour it on the polyvinylidene fluoride microporous filter membrane with a pore size of 0.2 μm soaked in 25% polyethylene glycol aqueous solution for 28 hours, scrape it with a scraper to form a film, and let it stand at room temperature 36h to make the cross-linking complete, and then soak the composite membrane in distilled water for 30 hours to dissolve the residual polyethylene glycol in the support layer. Finally, the composite membrane was dried under vacuum for 30 hours to obtain a PDMS / PVDF composite membrane with a total thickness of the composite membrane of 120 μm and a thickness of the skin separation layer of 30 μm. ...

Embodiment 3

[0030] Example 3 Preparation of pervaporation composite membrane

[0031] Its preparation method is as follows: according to the required mass ratio, take 6 parts of polymer PDMS, 3 parts of solvent n-hexane, 0.5 part of crosslinking agent tetraethyl orthosilicate and 0.05 part of curing agent dibutyltin dilaurate, mix them, stir them evenly and Stand to defoam, pour it on the polyvinylidene fluoride microporous filter membrane with a pore size of 0.45 μm soaked in 15% polyethylene glycol aqueous solution for 36 hours, scrape it with a scraper to form a film, and let it stand at room temperature 24 hours to complete the cross-linking, and then soak the composite membrane in distilled water for 36 hours to dissolve the residual polyethylene glycol in the support layer. Finally, the composite membrane was dried under vacuum for 36 hours to obtain a PDMS / PVDF composite membrane with a total thickness of the composite membrane of 135 μm and a thickness of the skin separation layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com