Thermal stable and super-hydrophobic ceramic-carbon nanotube composite membrane and application of membrane distillation water treatment thereof

A carbon nanotube composite and composite membrane technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve secondary pollution, membrane structure and membrane performance attenuation, shedding, etc. Problems, to achieve the effect of chemical corrosion resistance mechanical strength, good thermal stability, high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 Preparation of composite film partially covered by carbon nanotubes

[0045] Using the spinel hollow fiber membrane as a carrier to prepare a composite membrane partially covered by carbon nanotubes, the steps are:

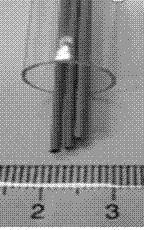

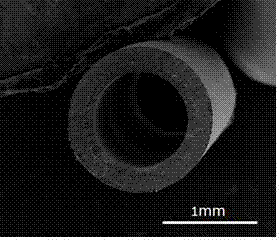

[0046] In the first step, the spinel hollow fiber ceramic membrane (see figure 1 ) Wash and soak with absolute ethanol for 10 minutes, then rinse with pure water, and dry at 60°C for 1 hour to obtain the treated carrier;

[0047] In the second step, the Ni(NO 3 ) 2 Prepared into a solution of 30% mass concentration, Ni(NO 3 ) 2 The solution was coated on the treated carrier, dried at 100°C for 2h, and then baked in a muffle furnace at 500°C for 2h. Through the analysis of X-ray diffractometer (XRD), it is concluded that the spinel hollow fiber membrane loaded with NiO catalyst is obtained in this step.

[0048] In the third step, the spinel hollow fiber membrane loaded with NiO catalyst is placed in the quartz reaction tube, and N2 and H ...

Embodiment 2

[0050] Embodiment 2 Preparation of composite film partially covered by carbon nanotubes

[0051] Using spinel hollow fiber membrane as a carrier, changing the CVD reaction time to prepare a composite membrane partially covered by carbon nanotubes, the steps are:

[0052] In the first step, the spinel hollow fiber ceramic membrane used as the carrier was washed and soaked with absolute ethanol for 10 minutes, then rinsed with pure water, and dried at 60°C for 1 hour to obtain the treated carrier;

[0053] In the second step, the Ni(NO 3 ) 2 Prepared into a solution of 35% mass concentration, Ni(NO 3 ) 2 The solution was coated on the treated carrier, dried at 100°C for 2h, and then baked in a muffle furnace at 500°C for 2h.

[0054] In the third step, the spinel hollow fiber membrane loaded with NiO catalyst is placed in the quartz reaction tube, and N 2 and H 2 (The flow rate is 25ml / min) For the spinel hollow fiber membrane loaded with NiO catalyst, reduce the catalyst ...

Embodiment 3

[0056] Embodiment 3 Preparation of composite membrane fully covered by carbon nanotubes

[0057] Using the spinel hollow fiber membrane as a carrier to prepare a composite membrane completely covered by carbon nanotubes, the steps are:

[0058] In the first step, the spinel hollow fiber ceramic membrane used as the carrier was washed and soaked with absolute ethanol for 10 minutes, then rinsed with pure water, and dried at 60°C for 1 hour to obtain the treated carrier;

[0059] In the second step, the Ni(NO 3 ) 2 Prepared into a solution of 30% mass concentration, Ni(NO 3 ) 2 The solution was coated on the treated carrier, dried at 100°C for 2h, and then baked in a muffle furnace at 550°C for 2h.

[0060] In the third step, the spinel hollow fiber membrane loaded with NiO catalyst is placed in the quartz reaction tube, and N 2 and H 2 (The flow rate is 20ml / min) For the spinel hollow fiber membrane loaded with NiO catalyst, reduce the catalyst at 500°C for 1h, then raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com