Preparation method of heterogeneous enhanced polyvinylidene fluoride hollow fiber membrane with high bursting strength

A polyvinylidene fluoride film-making technology, applied in the field of preparation of heterogeneously reinforced polyvinylidene fluoride hollow fiber membranes, can solve the problems of poor compatibility of inorganic/organic materials, uneven coating, and large performance differences and other issues to achieve the effect of improving compatibility, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

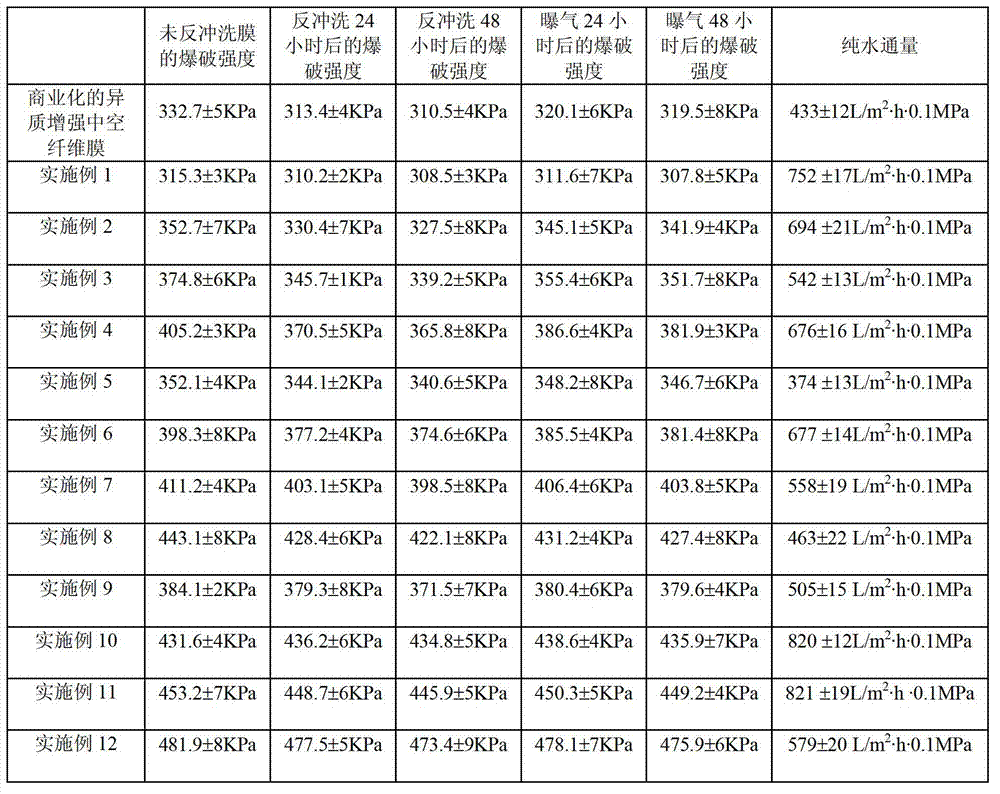

Examples

Embodiment 1

[0030] Dip a polyester fiber hollow braided tube with an inner diameter of 1.0 mm and an outer diameter of 1.6 mm in a mixed solution of 5% (mass concentration) of sodium hydroxide and 0.5% (mass concentration) of fatty alcohol polyoxyethylene ether AEO-7 , treated at 50°C for 30 minutes, washed with deionized water, and dried at 80°C; under the condition of nitrogen protection, polyvinylidene fluoride (PVDF) with a number average molecular weight of 200,000 was dissolved in N , N-dimethylacetamide (DMAC) prepared a dilute polyvinylidene fluoride solution with a mass concentration of 0.1%, soaked the polyester fiber hollow braided tube in the dilute polyvinylidene fluoride solution for 4 hours, and then took out the After being centrifuged at 3000 rpm for 5 minutes at a high speed, it was dried at 80° C. to obtain a pre-coated modified hollow braided tube.

[0031] Polyvinylidene fluoride (PVDF), polyvinylpyrrolidone PVP-K17, and N,N-dimethylacetamide (DMAC) were prepared in a...

Embodiment 2

[0033]A polyester fiber hollow braided tube with an inner diameter of 1.2 mm and an outer diameter of 1.8 mm is immersed in a mixed solution of 10% (mass concentration) sodium hydroxide and 1% (mass concentration) fatty alcohol polyoxyethylene ether AEO-7, Treat at 60°C for 20 minutes, wash with deionized water, and dry at 80°C; under nitrogen protection, dissolve polyvinylidene fluoride (PVDF) with a number average molecular weight of 100,000 in N, N-dimethylacetamide (DMAC) prepared a dilute polyvinylidene fluoride solution with a mass concentration of 0.5%, put the hollow braided polyester fiber tube in the dilute polyvinylidene fluoride solution and soaked it for 6 hours, then took it out and passed through 5000rpm After high-speed centrifugation for 10 minutes, dry at 80° C. to obtain a pre-coated modified hollow braided tube.

[0034] Polyvinylidene fluoride (PVDF), polyvinylpyrrolidone PVP-K17, N,N-dimethylacetamide (DMAC) according to the mass ratio of 25:15:60 to prep...

Embodiment 3

[0036] A hollow braided polyester fiber tube with an inner diameter of 1.4 mm and an outer diameter of 2.0 mm is immersed in a mixed solution of 20% (mass concentration) sodium hydroxide and 2% (mass concentration) fatty alcohol polyoxyethylene ether AEO-9, and the Treat at 70°C for 20 minutes, wash with deionized water, and dry at 60°C; under nitrogen protection, dissolve polyvinylidene fluoride (PVDF) with a number average molecular weight of 300,000 in N,N -Dimethylacetamide (DMAC) prepares a dilute solution of polyvinylidene fluoride with a mass concentration of 1%, puts the hollow braided polyester fiber tube in the dilute solution of polyvinylidene fluoride and soaks it for 8 hours, then takes it out and passes through a high-speed process of 8000rpm After being centrifuged for 30 minutes, it was dried at a temperature of 60° C. to obtain a pre-coated modified hollow braided tube.

[0037] Polyvinylidene fluoride (PVDF), polyvinylpyrrolidone PVP-K30, and N,N-dimethylacet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com