Composite polymer electrolyte for lithium ion battery and preparation method thereof

A composite polymer and lithium-ion battery technology, applied in secondary batteries, circuits, electrical components, etc., to achieve the effects of promoting lithium salt dissociation, improving dispersion performance, and inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

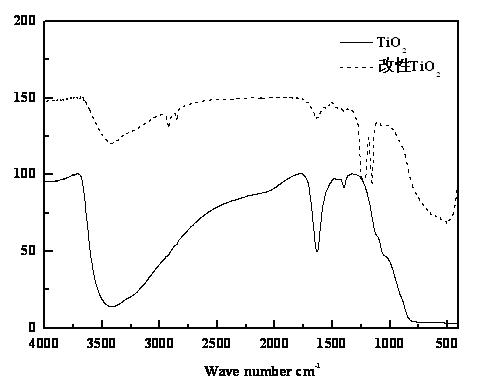

[0023] Example 1: Take 0.5 grams of nano-TiO with a hydrophilic surface and a particle size of 5-8nm 2 , dispersed in 100 milliliters of toluene, ultrasonically dispersed for 30 minutes, under mechanical stirring conditions, after slowly adding 2 milliliters of methoxypolyethylene glycol acrylate, the temperature was raised to 80 o C, continued to react for 6 hours, the white emulsion obtained was centrifuged, and the white solid obtained was washed three times with deionized water and dehydrated ethanol respectively, at 60 o C drying under vacuum conditions, that is, surface modified nano-TiO 2 . attached figure 1 The modified nano-TiO that this embodiment makes 2 Nano-TiO before modification 2 The Fourier transform infrared spectrum of the modified nano-TiO can be found 2 Significant C–H stretching and bending vibration absorption appeared in , indicating the efficient generation of surface-modified coatings. Get 0.05 gram of above-mentioned modified nano-TiO 2 Dis...

Embodiment 2

[0024] Example 2: Take 0.2 grams of nano-TiO with a hydrophilic surface and a particle size of 5-8nm 2 , dispersed in 100 ml of toluene, ultrasonically dispersed for 30 minutes, under mechanical stirring conditions, after slowly adding 0.5 ml of methoxypolyethylene glycol acrylate, the temperature was raised to 80 o C, continued to react for 12 hours, the white emulsion obtained was centrifuged, and the white solid obtained was washed three times with deionized water and absolute ethanol respectively, and was washed at 60 o C drying under vacuum conditions, that is, surface modified nano-TiO 2 . Get 0.1 gram of above-mentioned modified nano-TiO 2 Dispersed into 8 grams of acetonitrile solution of polyacrylonitrile-methyl acrylate copolymer (P(AN-MMA)) with a mass fraction of 5%, stirred for 2 hours, and coated the obtained uniform viscous solution on a clean glass plate on, cast film, at 60 o The polymer film obtained after evaporating the solvent under the condition C c...

Embodiment 3

[0025] Example 3: Get 1 gram of nano-SiO with a particle size of 20 nm obtained by hydrolysis of alkoxide 2 , dispersed in 100 ml of toluene, ultrasonically dispersed for 30 minutes, under mechanical stirring conditions, after adding 0.2 ml of methoxypolyethylene glycol acrylate, the temperature was raised to 80 o C, continue to react for 12 hours, the white emulsion of gained is centrifuged, and the white solid that obtains washes three times respectively with deionized water and absolute ethanol, at 60 o C dried under vacuum conditions to constant weight, that is, surface modified nano-SiO 2 . Take 1 gram of the above-mentioned modified nano-SiO 2 , 9 grams of acrylonitrile (AN), 0.09 grams of azobisisobutyronitrile (AIBN) and 30 milliliters of N,N-dimethylformamide (DMF) were dispersed into In a 100 ml three-necked flask, after ultrasonic dispersion for 2 hours, the temperature was raised to 60 after 0.5 hours of nitrogen gas oC, stirred for 24 hours, and the resultin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com