Fluorine-containing polysiloxane release agent and preparation method thereof

A polysiloxane and release agent technology, applied in the direction of coating, etc., can solve the problems of fluorine release agent containing harmful solvents, insufficient adhesion fastness of substrates, etc., to avoid pollution, reduce costs, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A fluorine-containing polysiloxane release agent, comprising the following components by weight:

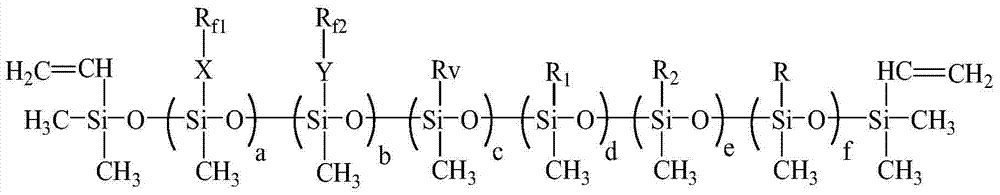

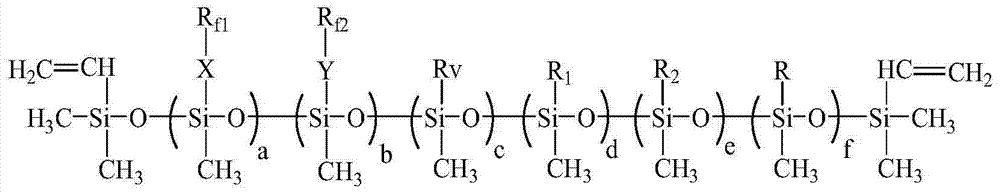

[0074] 100g viscosity is the vinyl fluorosilicone oil of 390mPa s (its structural formula is as shown in formula (1) below);

[0075] 3.25g hydrogen-containing silicone oil (its structure is shown in the following formula (2));

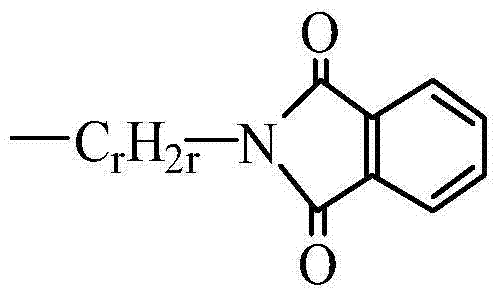

[0076] 0.1g fluorine-containing acetylenic alcohol inhibitor (its structure is shown in the following formula (3));

[0077] 500 ppm Karstedt platinum catalyst.

[0078]

[0079] The preparation method of this fluorine-containing polysiloxane release agent is:

[0080] Weigh each component respectively according to the formula of the above-mentioned fluorine-containing polysiloxane release agent;

[0081] The components are mixed to obtain a mixed material.

Embodiment 2

[0083] The fluorine-containing polysiloxane release agent was prepared according to the formulation components and steps of the above-mentioned Example 1, wherein the structure of the hydrogen-containing silicone oil remained unchanged, and the amounts of the fluorine-containing acetylenic alcohol and the platinum catalyst remained unchanged. Compared with Example 1, the difference is that the degree of polymerization of the chain unit of the vinyl fluorosilicone oil in this example changes, that is, a=60, b=10, d=8, f=180, and the a, b, d , f value and Si-H and CH=CH 2 Based on the molar ratio of 2:1, add the corresponding mass of hydrogen-containing silicone oil.

Embodiment 3

[0085] The fluorine-containing polysiloxane release agent was prepared according to the formulation components and steps of the above-mentioned Example 2. Compared with Example 2, the difference is that the degree of polymerization of the chain unit of vinyl fluorosilicone oil in this example changes, that is, a=90, b=11, d=5, f=220, and the a, b, d , f value and Si-H and CH=CH 2 Based on the molar ratio of 2:1, add the corresponding mass of hydrogen-containing silicone oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com