Ultraviolet cross-linking oil-resistant low-smoke halogen-free flame retardant polyolefin cable material and preparation method thereof

A technology of polyolefin cable materials and ultraviolet light, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of complex flame-retardant polyolefin cable materials, low oil resistance, and high cost of cross-linking equipment, and achieve production High efficiency, improved oil resistance, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

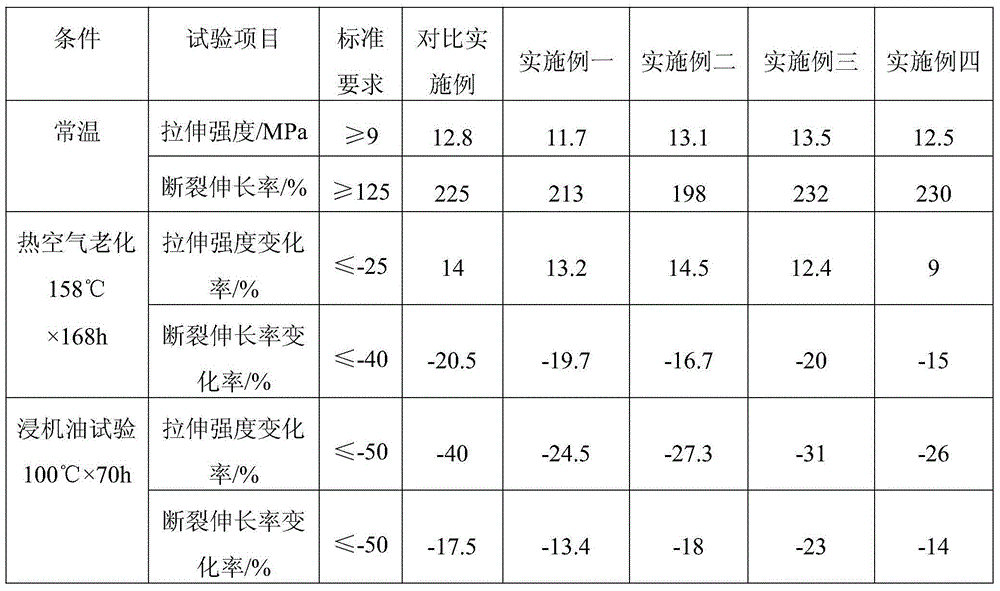

Examples

specific Embodiment approach 1

[0023] Specific Embodiment 1: In this embodiment, an ultraviolet cross-linked oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material consists of 100 parts by weight of base material, 120-130 parts of halogen-free flame retardant, and 1-3 parts of cationic Initiator, 1-3 parts of free radical initiator, 2-5 parts of multifunctional crosslinking agent, 5-10 parts of flame retardant synergist, 1-5 parts of smoke suppressant, 0.1-0.5 parts of composite antioxidant and 0.5 parts ~1.2 parts of lubricant;

[0024] The base material is ethylene propylene ethyl ester copolymer, ethylene-acrylate-carbonyl terpolymer, ethylene methyl acrylate copolymer, ethylene butyl acrylate copolymer, low-density polyethylene, linear low-density polyethylene, ethylene - α-octene polymer, EPDM rubber, styrene-based thermoplastic elastomer, glycidyl methacrylate grafted ethylene vinyl acetate copolymer, maleic anhydride grafted vinyl acetate copolymer, maleic anhydride Grafte...

specific Embodiment approach 2

[0032] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the cationic initiator is didodecylbenzene hexafluoroarsenic acid iodonium salt, 4,4'-dimethyldiphenyliodonium One or a mixture of phosphate, triarylsulfonium hexafluorophosphate and ferrocene hexafluorophosphate, mixed in any ratio when it is a mixture. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the flame retardant synergist is one or more of hydrotalcite, zinc borate, montmorillonite, wollastonite and silica-alumina powder The mixture of species is mixed in any ratio when it is a mixture. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com