Composite rotor blade for unmanned helicopter and manufacturing method thereof

A technology for unmanned helicopters and rotor blades, which is applied in the field of unmanned helicopter composite rotor blades and its production, can solve the problems of increasing the manufacturing cost of rotor blades, achieve compact structure, reduce the number of molds, and have good shape accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

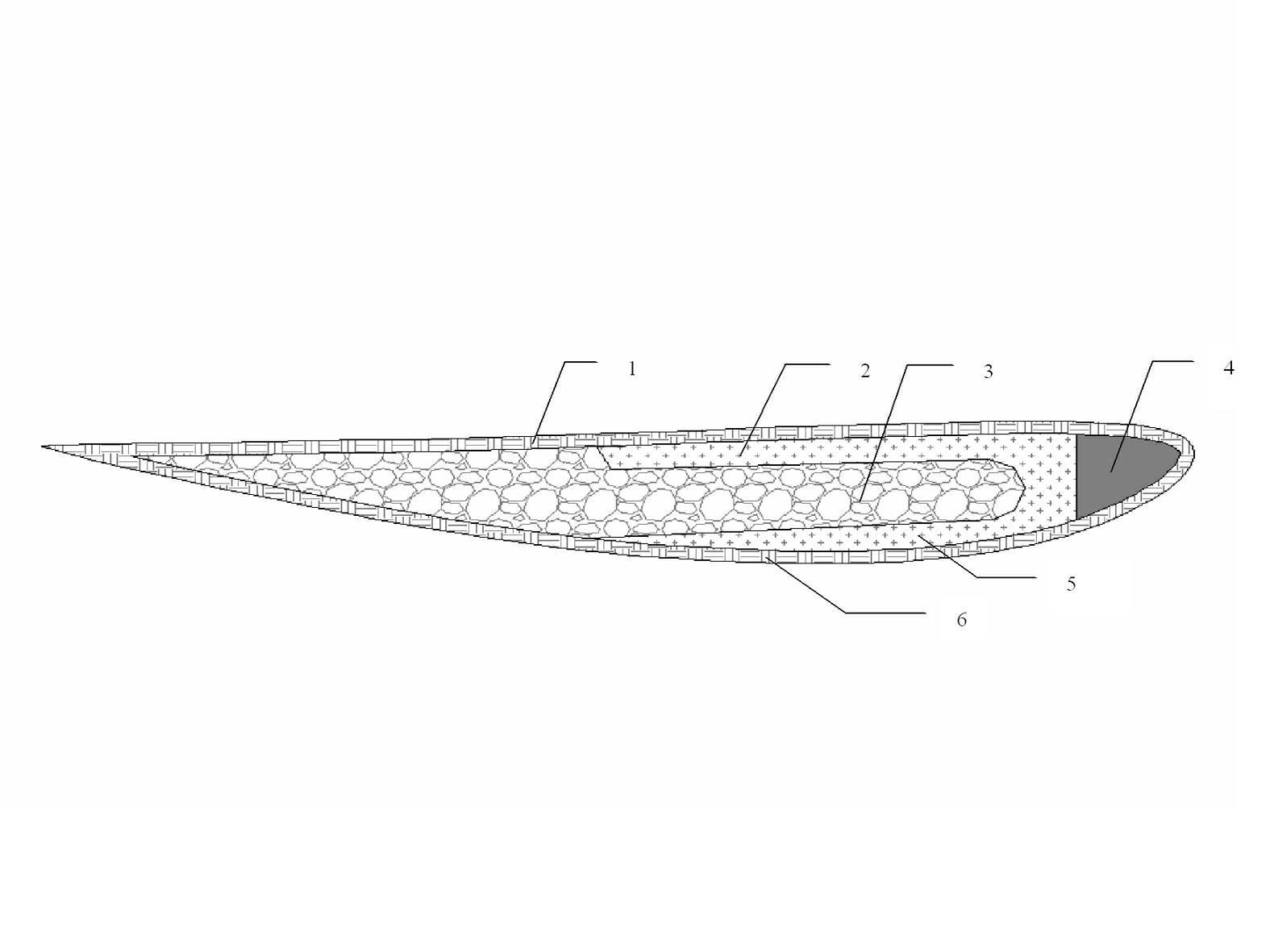

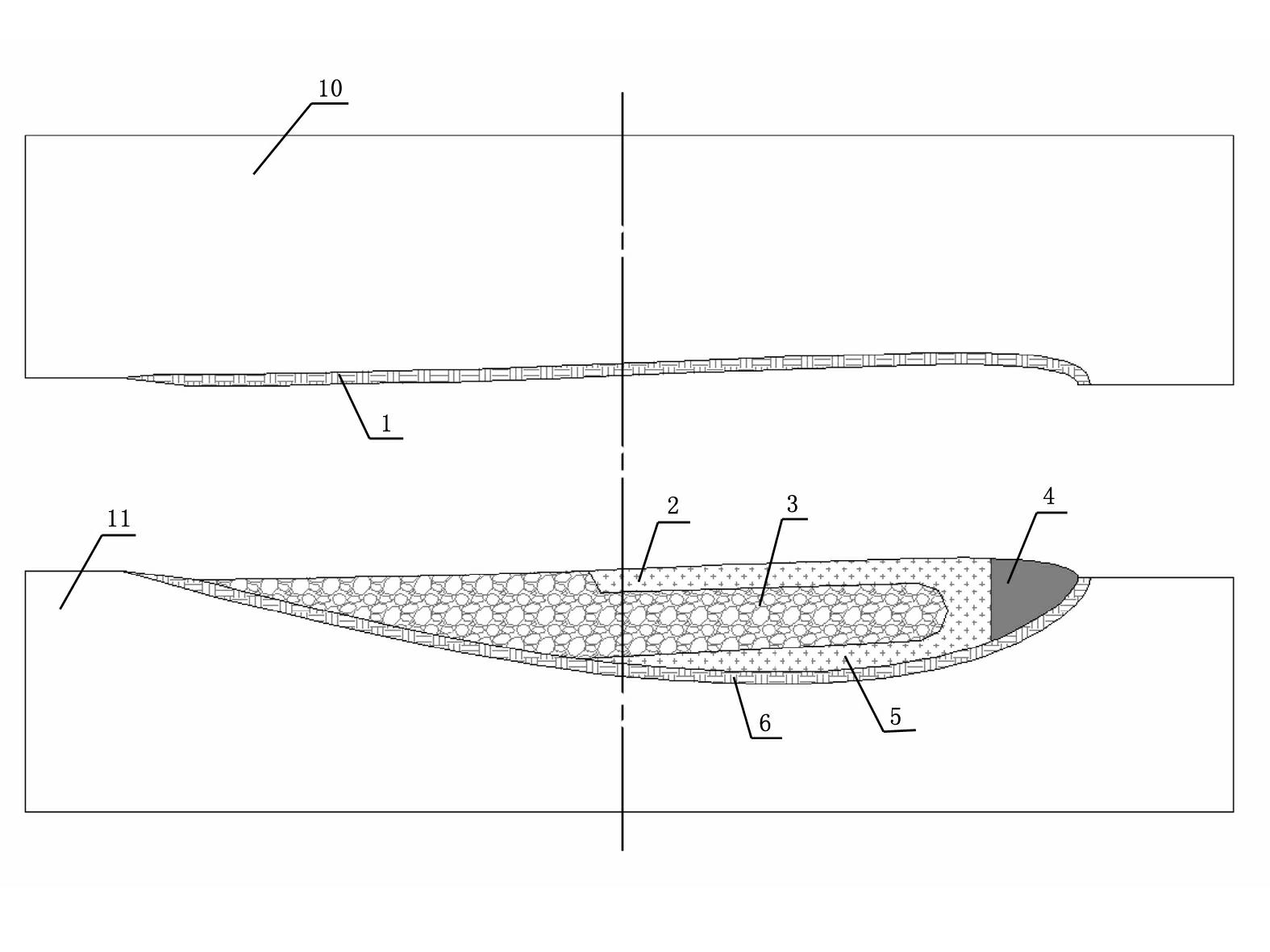

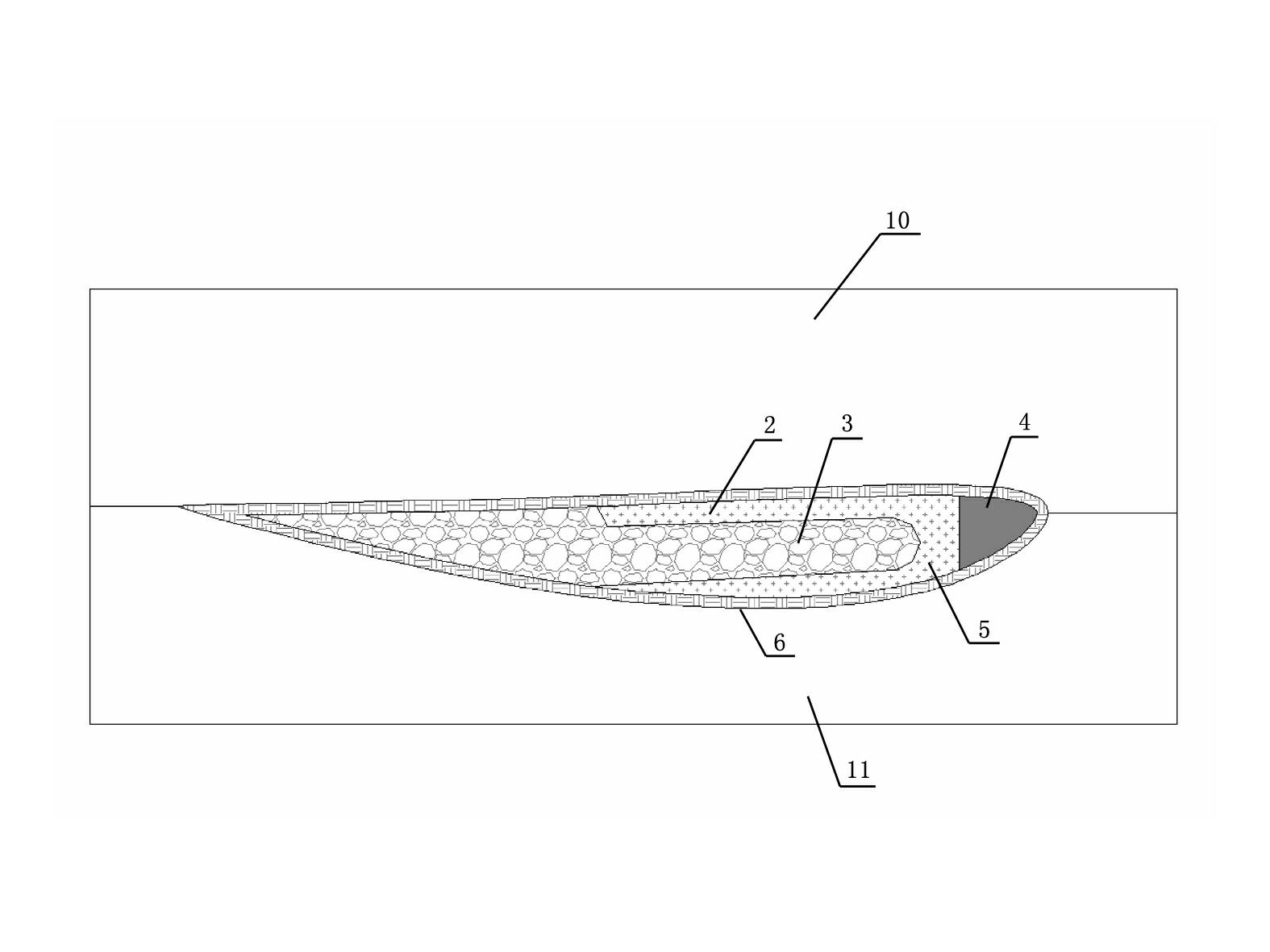

[0031] Refer to attached Figure 1~4 , the unmanned helicopter composite material rotor blade includes an upper airfoil skin 1, a lower airfoil skin 6, an upper airfoil portion 2 of a C-shaped beam, a lower airfoil portion 5 of a C-shaped beam, and a leading edge counterweight lead strip 4, Propeller root bushing 7, foam core 3, propeller tip counterweight lead weight 8 and propeller tip trailing edge counterweight tube 9. as attached figure 1 And attached figure 2 As shown, the upper airfoil skin 1 and the lower airfoil skin 6 are closed to form the shape of the blade. The lower airfoil part 5 of the girder is combined into a C-shaped girder. The C-shaped girder is close to the leading edge counterweight lead strip 4. The rear edge of the C-shaped girder is filled with a foam core 3. For the purpose of adjusting the balance, the front part of the blade is solidified with a tip counterweight. Lead block 8 and weight tube 9 at the trailing edge of the blade tip, and a blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com