Gypsum wood fiber structural insulated panel arrangement

a technology of structural insulation and gypsum wood fiber, which is applied in the direction of building components, buildings, constructions, etc., can solve the problems of reducing the use value of the panel, increasing the cost of the panel, and preventing the use of the panel in many types of common structures, etc., and achieves the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

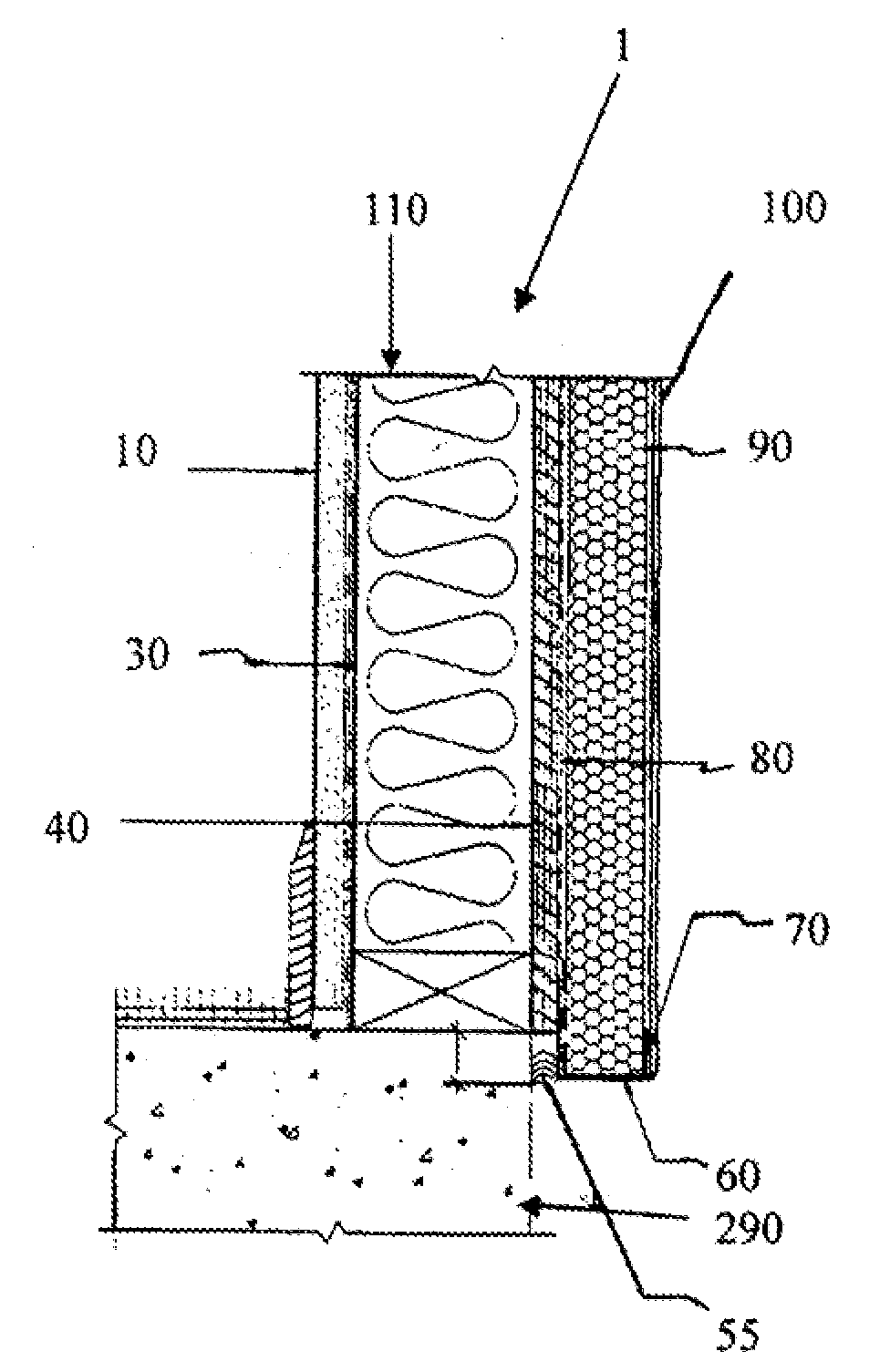

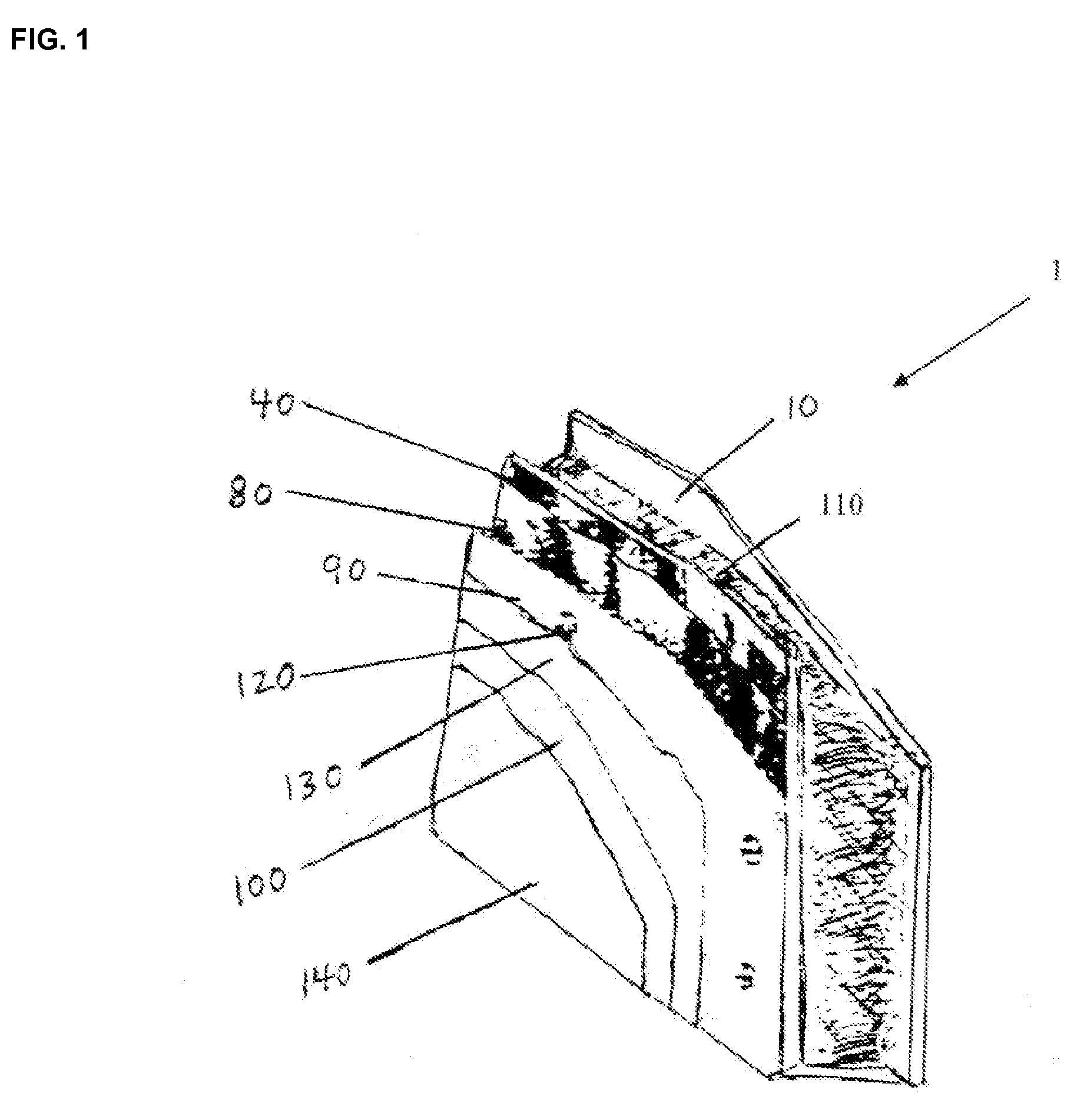

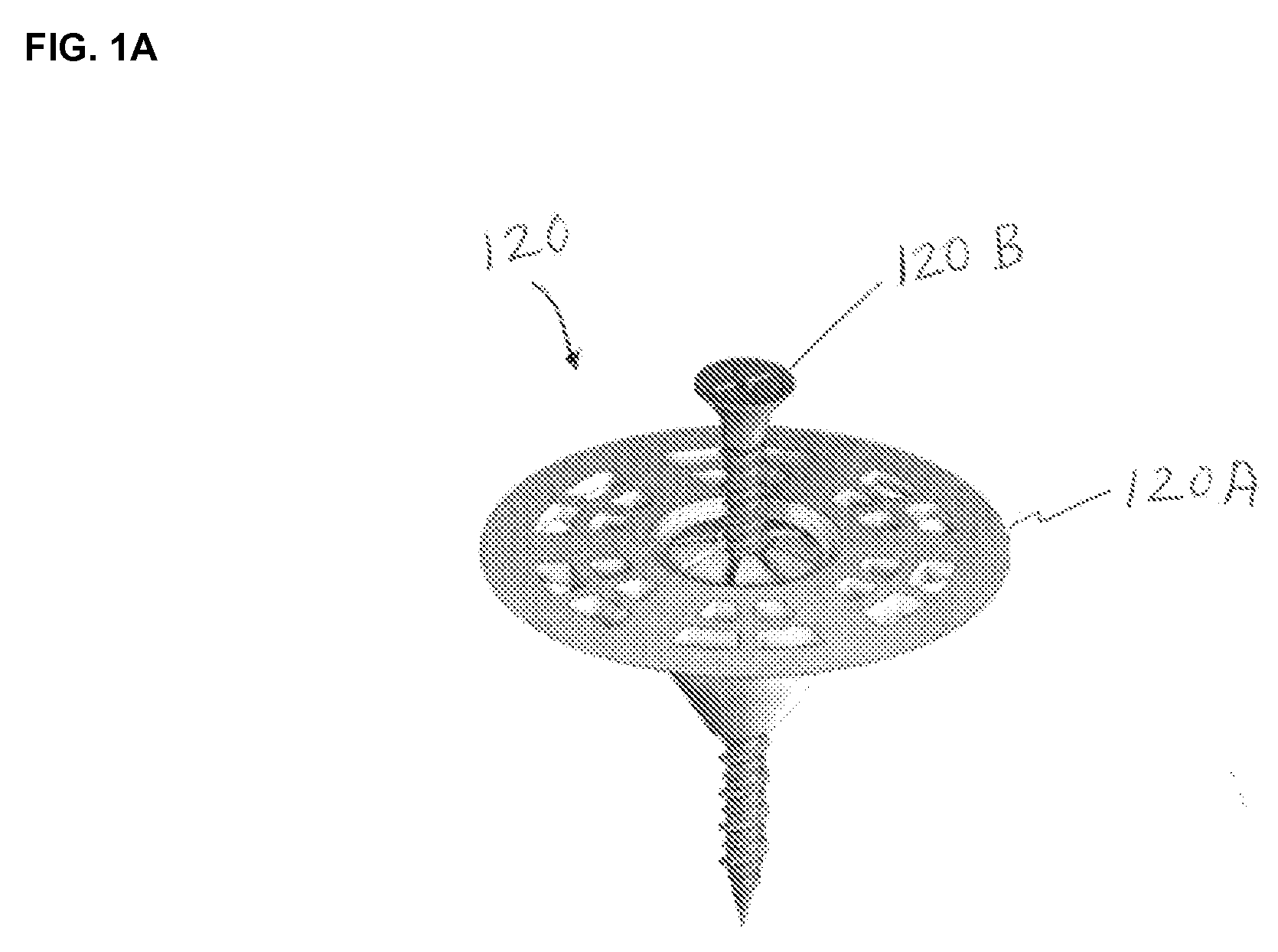

[0053]SIP panels are manufactured by Stress Panel Manufacturing using 1.27 cm. (½ in.) FIBEROCK® brand sheathing panels adhesively attached on both sides of either 8.89 or 16.51 cm. (3.5 or 6.5 in.) thick polystyrene foam. The panels were created using 31.78 kg / m3 (2 lb / ft3) expanded polyethylene foam (EPS foam). A total of six 1.22×2.44 m. (4×8 ft) panels were tested to determine the load capacity of the system. Tests were conducted according to ASTM E-72-05 and ASTM E-330. The axial load tests were conducted on the panels without splines.

[0054]A 11.43 cm. (4½ in.) thick panel was cut vertically into a 61 cm. (24 in.) strip and the 2.44 m. (8 ft) tall section axially loaded to failure. Loading was conducted by placing flat steel plates at the top and bottom of the specimen and placing the loading ram ⅙ of the panel thickness away from the center of the panel, as described in ASTM E-72-05. The load at failure was approximately 8636.4 kg. (19,000 lb), which is equivalent to an ultima...

example 2

[0061]Tests were conducted according to ASTM C514-04 to determine the amount of force required to remove various fasteners from 1.27 cm. (½ in.) FIBEROCK® brand gypsum wood fiber panels available commercially from United States Gypsum Company, Chicago, Ill., USA. Results were also obtained for 1.48 cm. ( 7 / 16 in.) panels of oriented strand board (OSB) and plywood, meeting ASTM commercially available from a number of suppliers such as Louisiana Pacific and Weyerhaeuser. Results are shown in TABLE 1, below.

[0062]From the table it was found that the 1.27 cm. (0.50 in.) FIBEROCK® brand gypsum wood fiber sheathing would not hold nails and thus for any particular application where bonding strength was required, screws would need to be used.

TABLE 1Nail-holding Strength in Kg (lbs.)1.27 cm.0.4860.486 cm.FIBEROCK ® BrandFastener Descriptioncm. OSBPlywoodSheathing1½ in. roofing nails23.221.43.646 d nails33.226.44.551½ in. G screws132.7155.539.541¼ in. drywall101.8131.838.2screws1⅝ in. drywall...

example 3

[0064]Tests were conducted to determine the shear strength of various fasteners in FIBEROCK® brand sheathing. This data may be used to determine the number of fasteners required to attach SIPS panels to footers and headers.

[0065]Tests were conducted by attaching 5.08×15.24×1.91 cm. (2×6×¾ in.) plywood to 15.24 cm.×15.24 cm.×1.27 cm. (6 in.×6 in.×0.5 in.) FIBEROCK® brand sheathing and to 15.24 cm.×15.24 cm.×1.525 cm. (6 in.×6 in.×⅝ in.) FIBEROCK® brand sheathing using single fasteners. These fasteners are either USG Exterior Sheathing Screws, standard drywall nails or 3.81 cm. (1½ in.) long staples with 0.635 cm. (¼ in.) crowns. In each case, the fastener was 1.91 cm. (¾ in.) from the edge of the panel.

[0066]Shear strength to failure values for various fasteners used for joining FIBEROCK® brand gypsum wood fiber board sheathing to plywood obtained from the testing are shown in the bar graph in FIG. 10. For each configuration, five samples were evaluated. For screws in 1.27 cm. and 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| corrosion resistant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com