Capon operation table

An operating table and capon technology, which is applied in the field of capon operating tables, can solve the problems of large size, inconvenient portability, operation, assembly and disassembly of the operating table, and achieves high operation efficiency, good economic and social benefits, portability and convenience. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

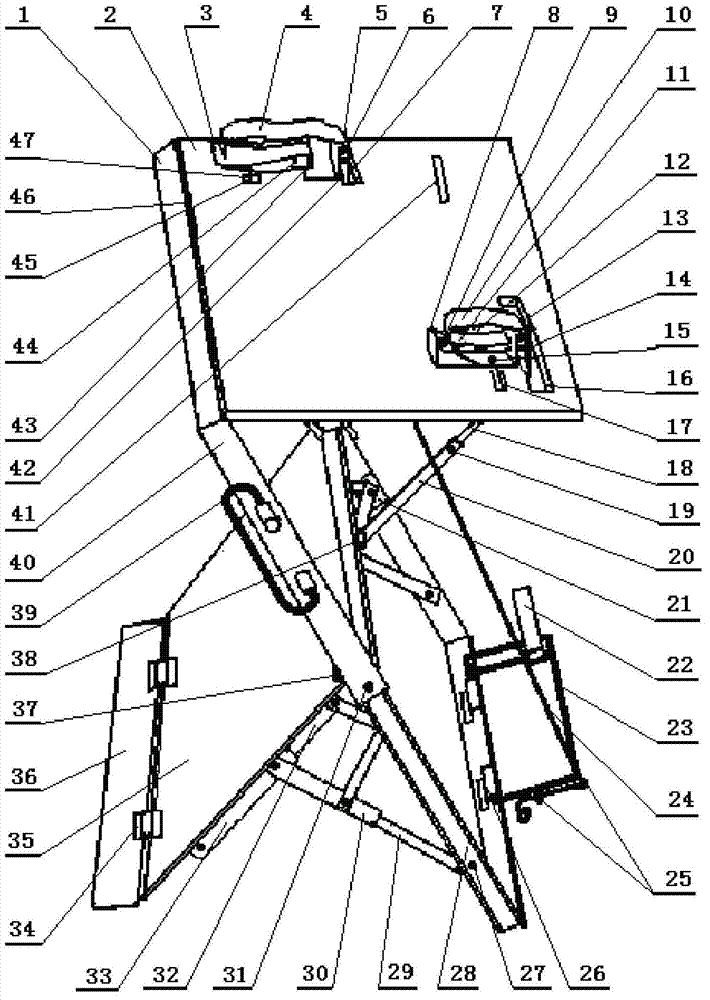

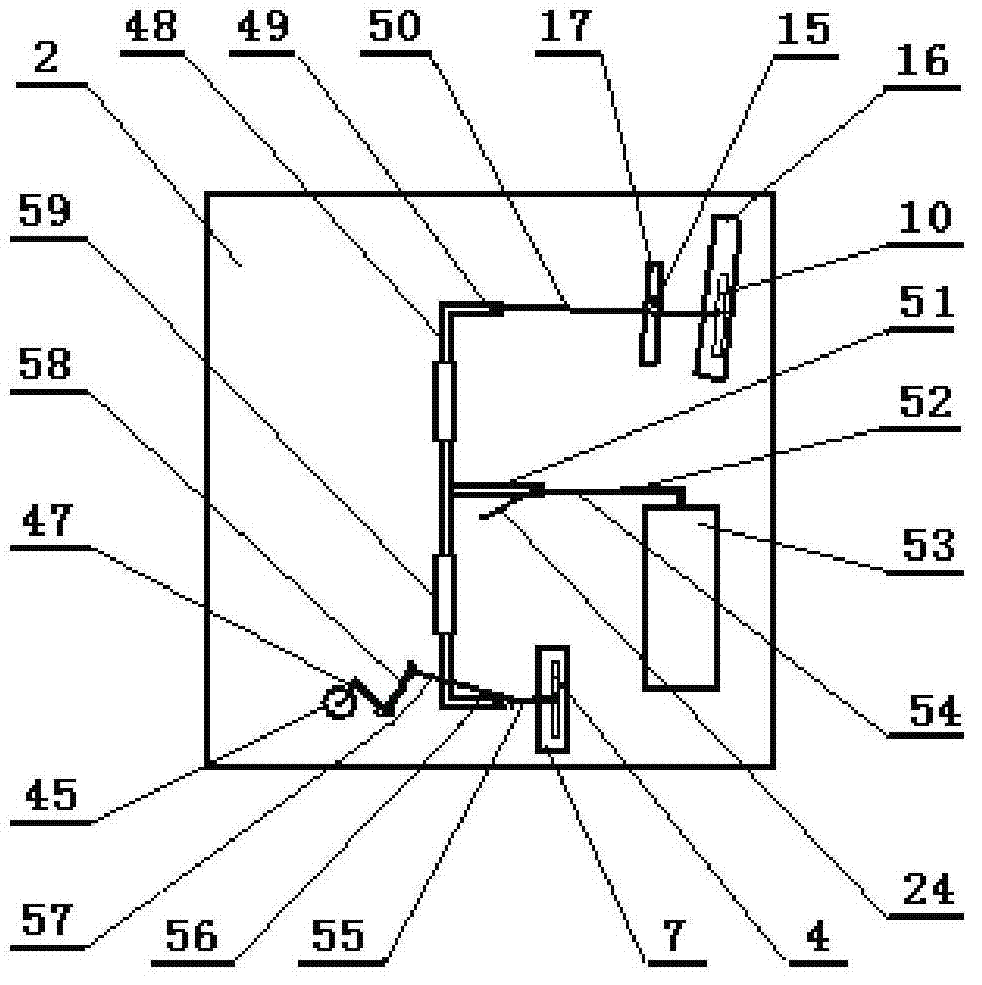

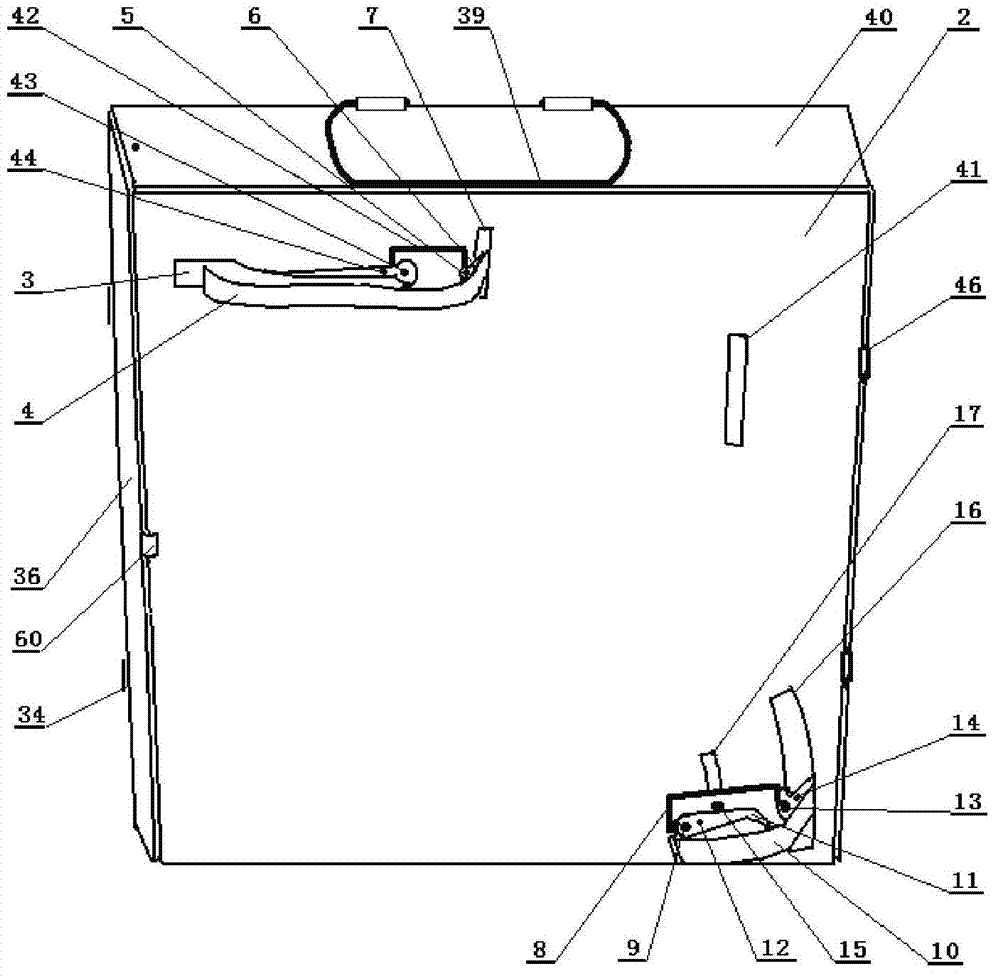

[0029]The capon operating table of this example, its structure includes setting platen 2 and telescopic supporting frame 1, and described platen 2 is provided with counting hole 41, fixed large clamp, fixed small clamp, large upper clamp movable hole 7, large lower clamp pull wire Hole 45, small upper clamp displacement movable hole 16, small clamp fixed displacement slot 17; described fixed large clamp and fixed small clamp are respectively located on the surface close to the platen 2 corresponding to both sides of the platen 2, and the fixed large clamp The clamp is fixed on the platen 2 by the large clamp fixing seat 42, and the small clamp is fixed on the platen 2 by the small clamp fixing seat 8 through the small clamp fixing bolt 15 on the platen 2 of the small clamp fixing displacement slot 17; the platen 2 adopts a platform The board leaflet 46 is connected with the supporting frame 1 . Among them, the large fixed clamp is provided with a large upper clamp 4, a large u...

Embodiment 2

[0037] The capon operating table of this example, its structure includes setting platen 2 and telescopic supporting frame 1, and described platen 2 is provided with counting hole 41, fixed large clamp, fixed small clamp, large upper clamp movable hole 7, large lower clamp pull wire Hole 45, small upper clamp displacement movable hole 16, small clamp fixed displacement slot 17; described fixed large clamp and fixed small clamp are respectively located on the surface close to the platen 2 corresponding to both sides of the platen 2, and the fixed large clamp The clamp is fixed on the platen 2 by the large clamp fixing seat 42, and the small clamp is fixed on the platen 2 by the small clamp fixing seat 8 through the small clamp fixing bolt 15 on the platen 2 of the small clamp fixing displacement slot 17; the platen 2 adopts a platform The board leaflet 46 is connected with the supporting frame 1 . Among them, the large fixed clamp is provided with a large upper clamp 4, a large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com