Construction method for pipe retreating of cross-river pipe jacking pipeline in soft soil stratum

A construction method and pipeline technology, applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, filling, etc., can solve the problems of high technical requirements for pipe withdrawal speed, soil backfilling, stratum subsidence, surface subsidence, etc., and achieve convenience Effects of soil injection speed, prevention of subsidence, and convenience of soil injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the embodiments are only for illustrating the present invention, but not limiting the scope of the present invention in any form.

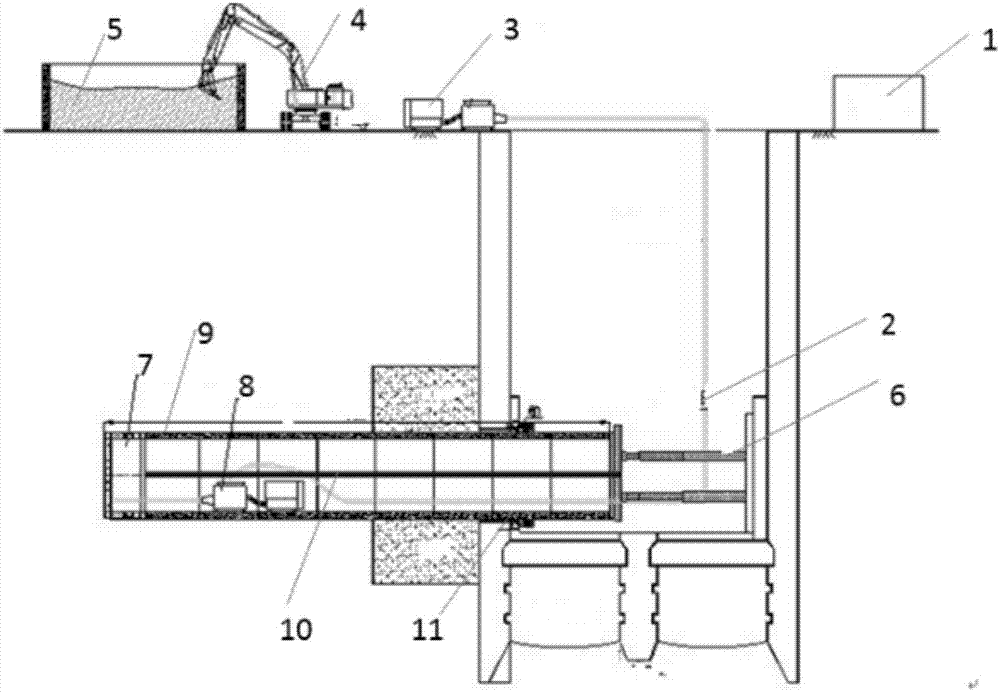

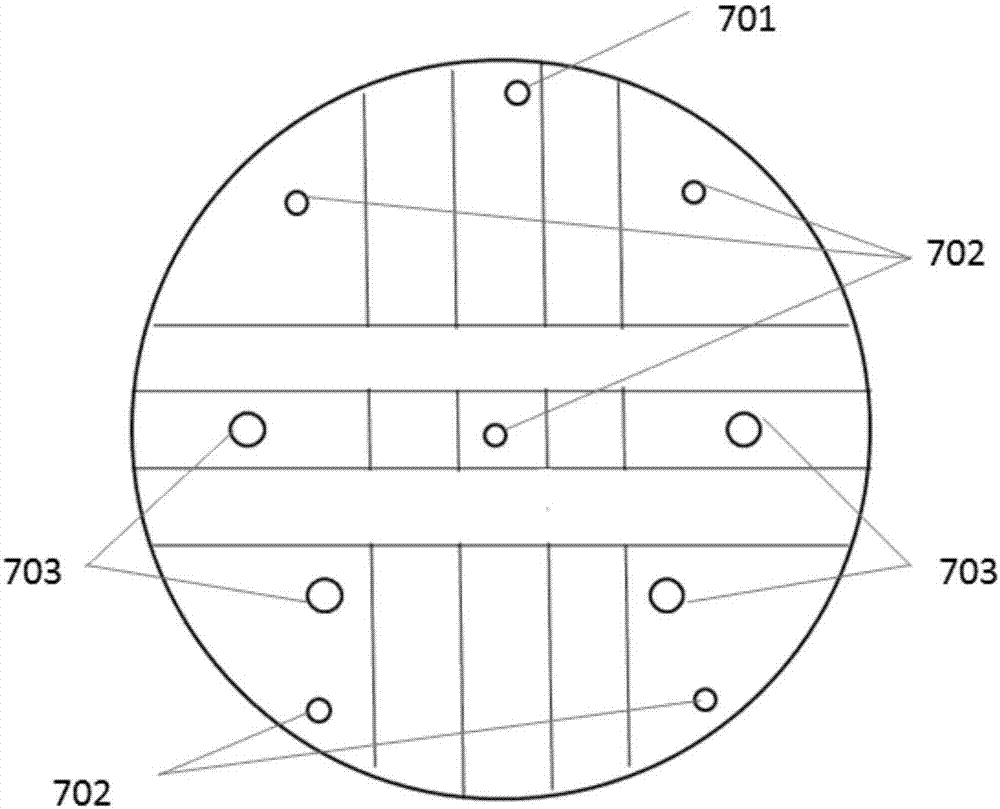

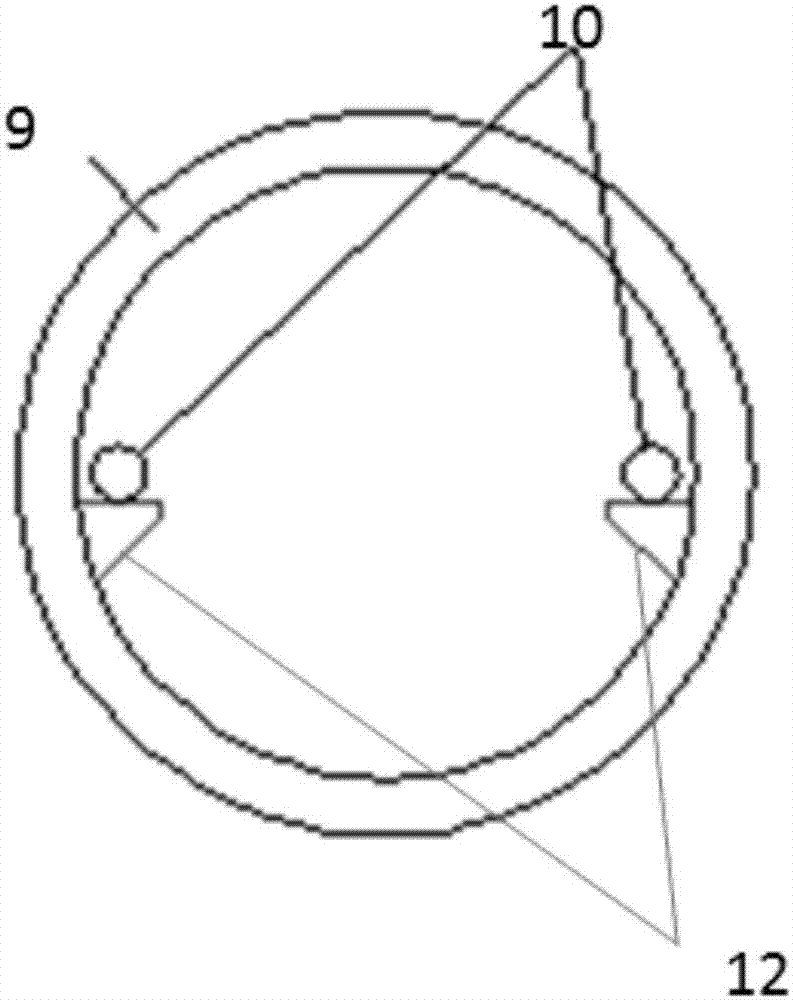

[0045] figure 1 It is a schematic diagram of the pipeline filling system in a preferred embodiment of the present invention, wherein 1 is the control room, 2 is the slurry delivery pipe, 3 is the first soil and sand pump, 4 is the excavator, 5 is the soil collection pit, and 6 is the reverse top hydraulic cylinder. 7 is a steel seal door, 8 is a second soil sand pump, 9 is a pipeline for withdrawing, 10 is a steel strand group, and 11 is a reverse pull steel beam. When desiring to retreat the pipeline 9, it is necessary to backfill the soil body simultaneously. This construction method is to backfill the steel-sealed door 7 rears with earth slurry or cement slurry through the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com