Cable controller, kite, kite drive operating mechanism, kite power generator and automobile and boat wind-driving method

A working machine and cable machine technology, which is applied to the mechanism of repeatedly retracting and releasing cables according to the same length, high-drop hydroelectric power generation mechanism, kite or water kite, and kite mechanism field, which can solve the problem of easy fatigue of the kite body, low maintenance cost, and wing section problems. Problems such as low wind collection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

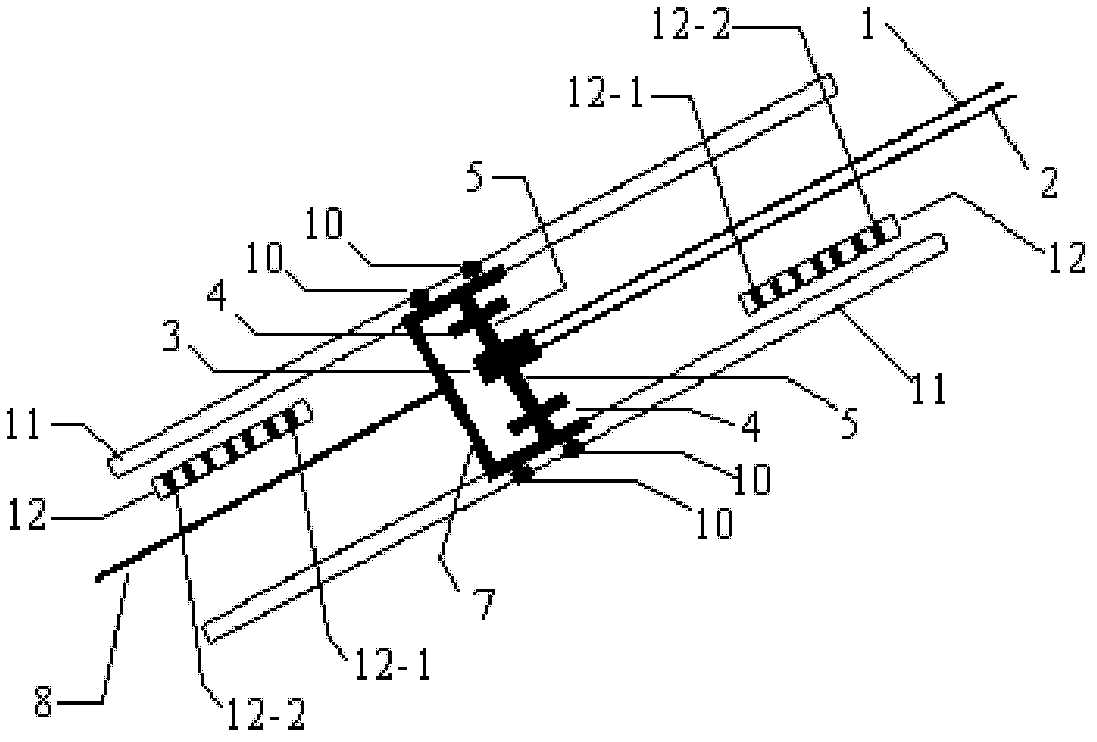

[0305] Embodiment 1 of the cable control machine: as figure 1 As shown, the main text description is found in the paragraph "selection of the non-motor type of this scheme" on page 5 of this paper (in this manual), the shaft 5 is also fixedly connected with the wheel 3, and the cable 1 and the cable 2 are wound on the Wheel 3, and the ends of the two cables are respectively fixedly connected to the wheel arc surface, and the length of each cable wrapped around the wheel is not less than the required telescopic length of the other end of the cable.

Embodiment 2

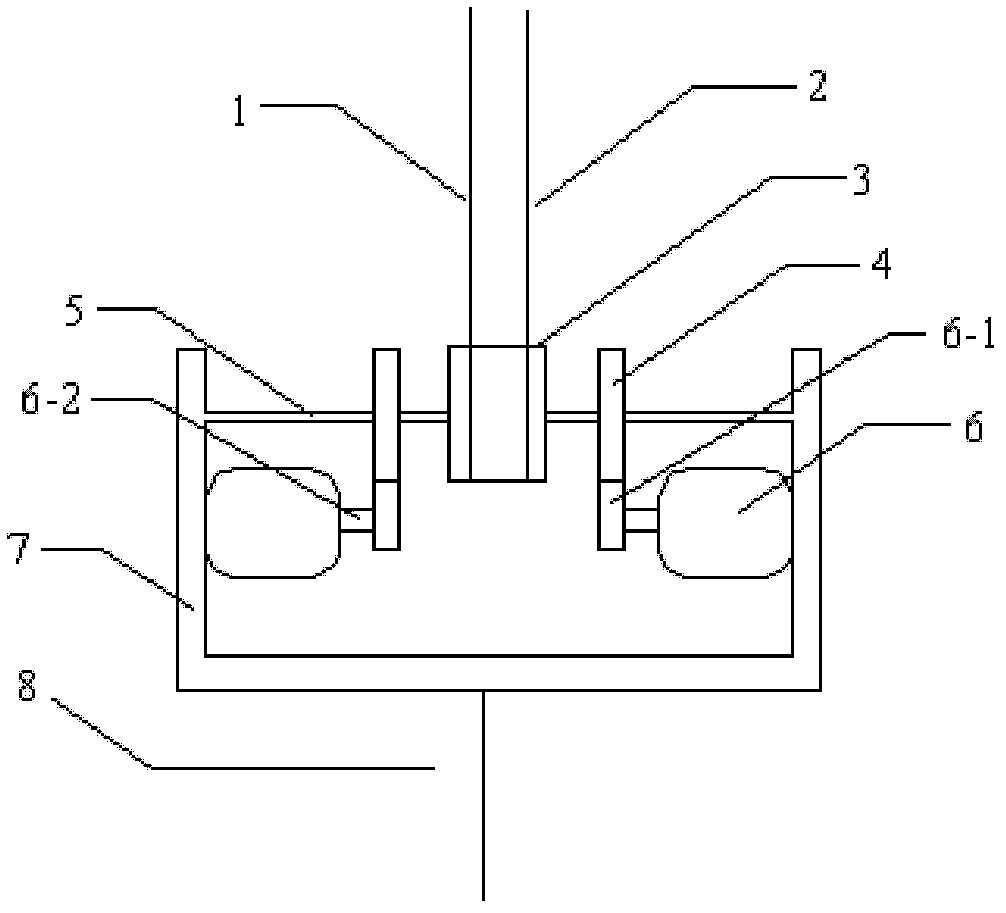

[0306] Example two of the cable control machine: as figure 2 As shown, the two ends of the shaft 5 are respectively fixedly connected to the inner ring of a bearing, and the outer rings of the two bearings are respectively fixedly connected to the two arms of the bracket 7; the shaft 5 is fixedly connected to the two wheels 4, and the two wheels 4 are respectively connected to a The wheel 6-1 on the shaft of the motor 6 is connected, and the wheel 4 is a gear or a pulley fixedly connected to the shaft 5, and the driving wheel of the motor 6 is also a paired gear or a pulley; both motors are unidirectional rotary motors and The two motors drive the wheel (4) to rotate in the opposite direction; the inner circle, the outer circle of the wheel 4 and the intermediate mechanism of the two circles form a ratchet mechanism, an overrunning clutch or other mechanisms with similar functions, and the direction of rotation of the two wheels is the outer circle. The rotation direction of ...

Embodiment 3

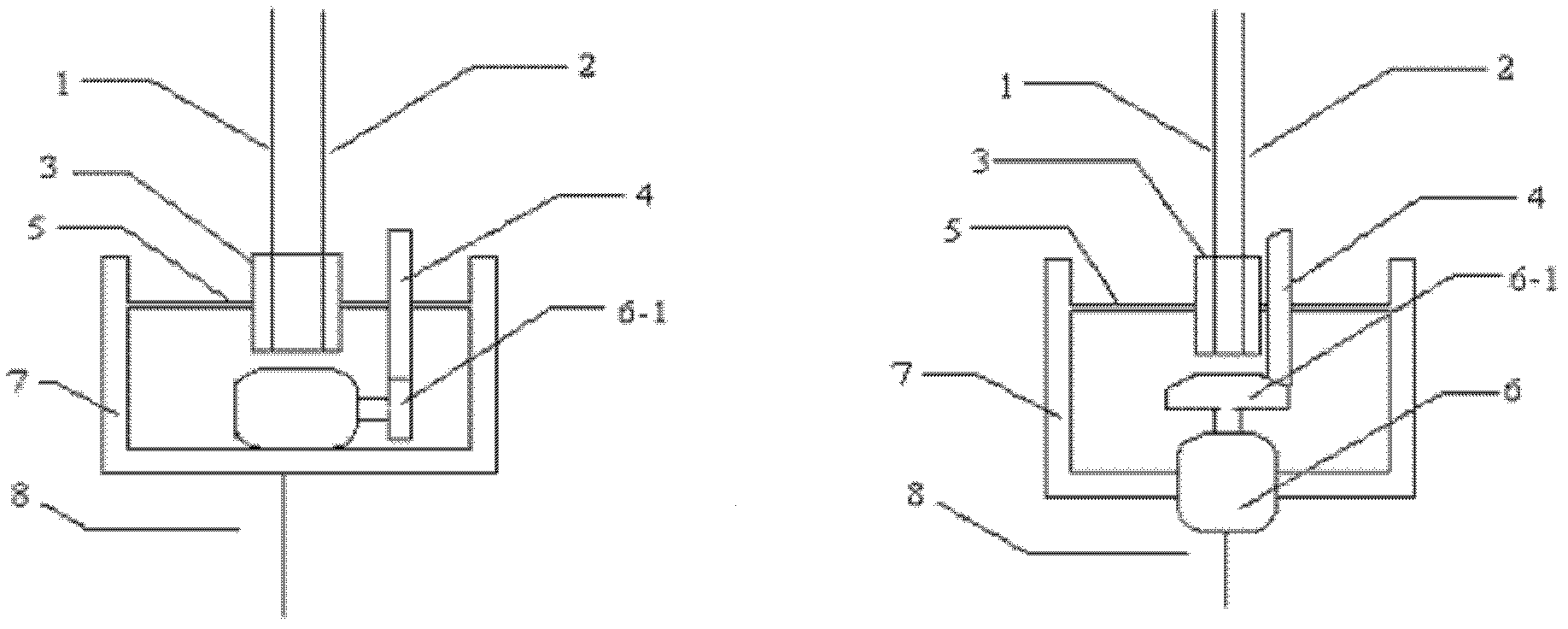

[0307] Example three of the cable control machine: as image 3 As shown, the structure is basically the same as that of Embodiment 2, except that the motor is reduced to one (a motor that can rotate in both directions), and the wheel 4 is fixedly connected to the shaft 5 and rotates synchronously, and the shaft of the wheel 6-1 and the motor is also fixedly connected and rotates synchronously ; image 3 The structure of the right figure is basically the same as that of the left figure, only the wheel 6-1 and the wheel 4 are changed into bevel gears meshing with each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com