Fast installation formwork and connection structure

It is a fast technology for installing formwork, which is applied in the connection parts of formwork/formwork/work frame, formwork/formwork components, infrastructure engineering, etc. It can solve the problems that cannot be directly used, the formwork strength is not high, and the connection structure cannot be directly used. Use and other problems to achieve the effect of convenient and quick handling and installation, improved installation strength and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

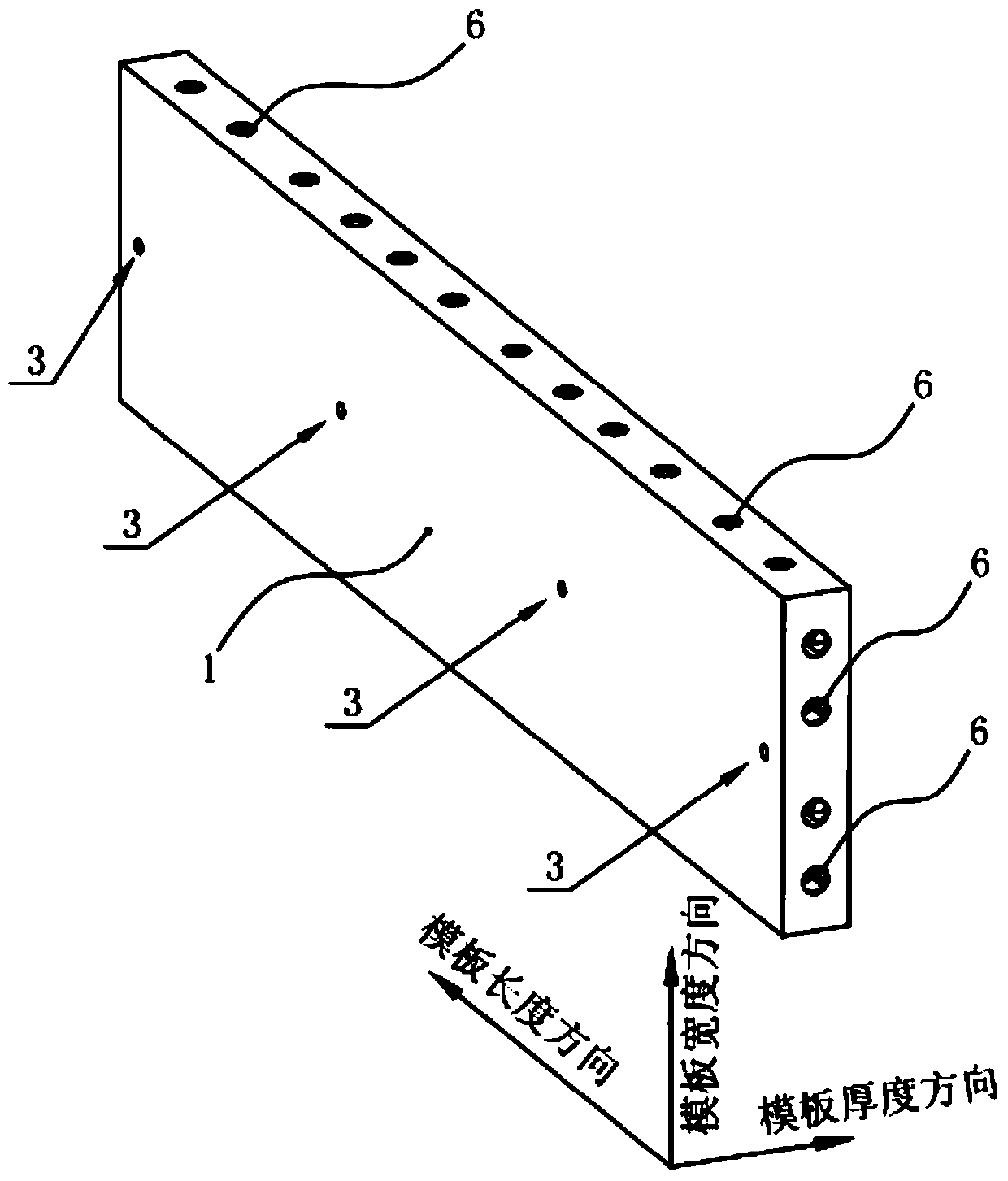

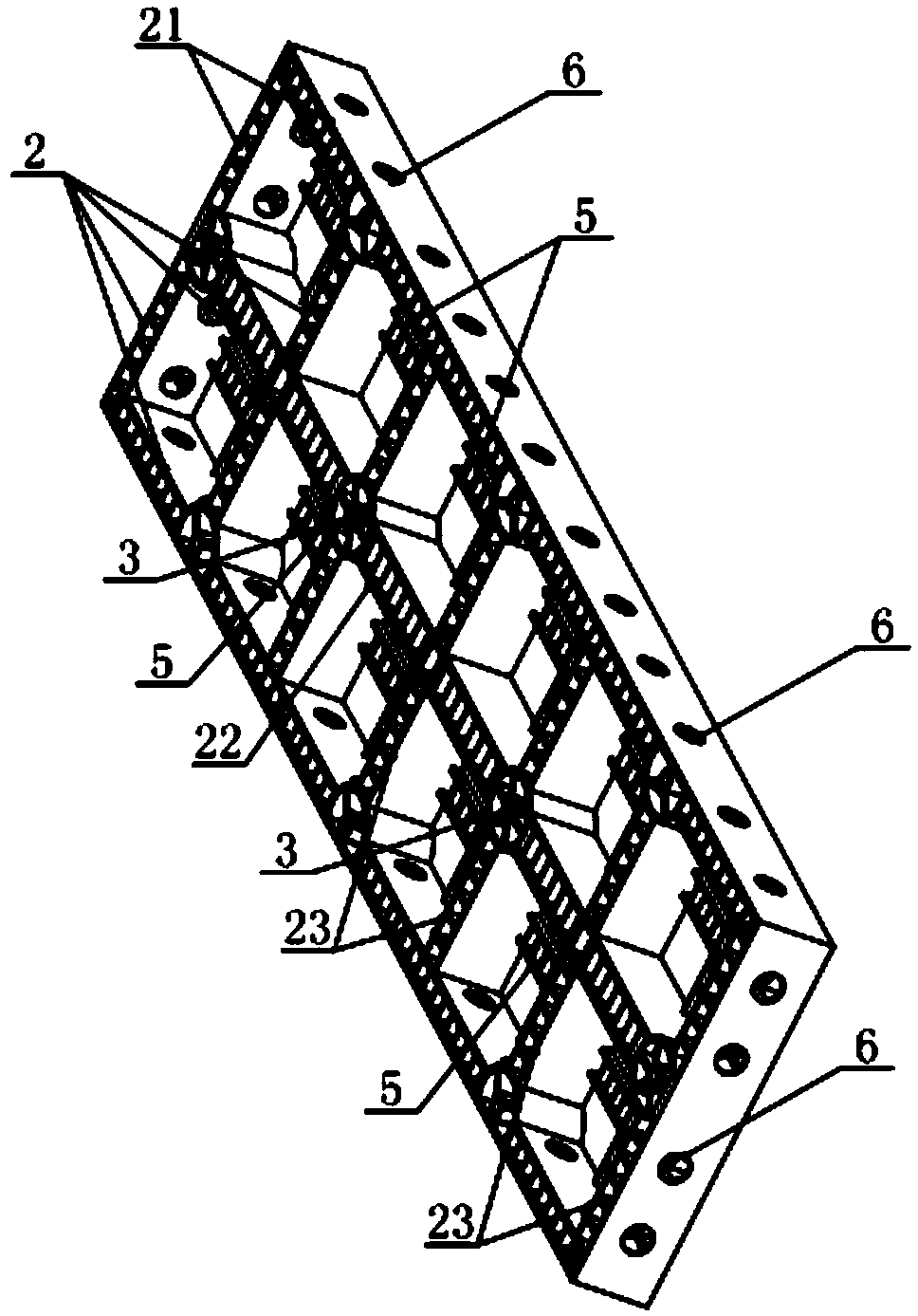

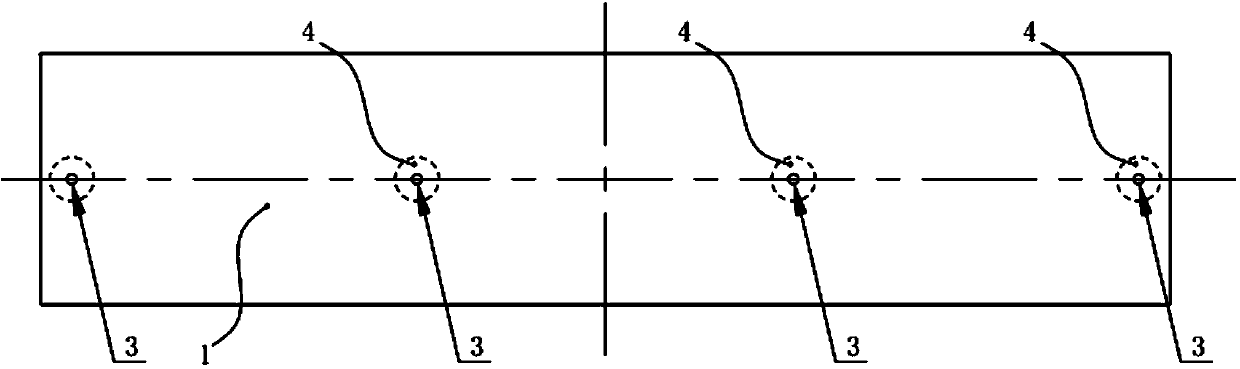

[0048] Such as Figure 1 to Figure 4 As shown in , the quick installation formwork overall adopts a size structure of 180cm×60cm×8cm, and its material is plastic; three horizontal reinforcing ribs 22 and seven vertical reinforcing ribs 23 are arranged on its back. Among them, two transverse reinforcement ribs 22 and two vertical reinforcement ribs 23 form a circumferential reinforcement rib 21; four opposite pull holes 3 are arranged on the template, and the four opposite pull holes 3 are located on the center line of the template length direction; The paired holes 3 at both ends are 5 cm away from the nearest side, and the two middle holes 3 divide the form evenly; Moreover, a structure of annular reinforcing ribs 24 and radial reinforcing ribs 25 is provided around the pull hole 3 . A circular stainless steel reinforcement 4 is embedded in the smooth panel 1 around the pull hole 3 . Moreover, the thickness of the smooth panel 1 is 1 cm, the height of the main rib 2 is 7 cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com