Method for building wall

A technology of wall and combined formwork, which is applied in building construction, building material processing, walls, etc., can solve the problems of large concrete color difference, large error, and unguaranteed overall effect of the wall, etc., and achieves simple construction and beautiful wall surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

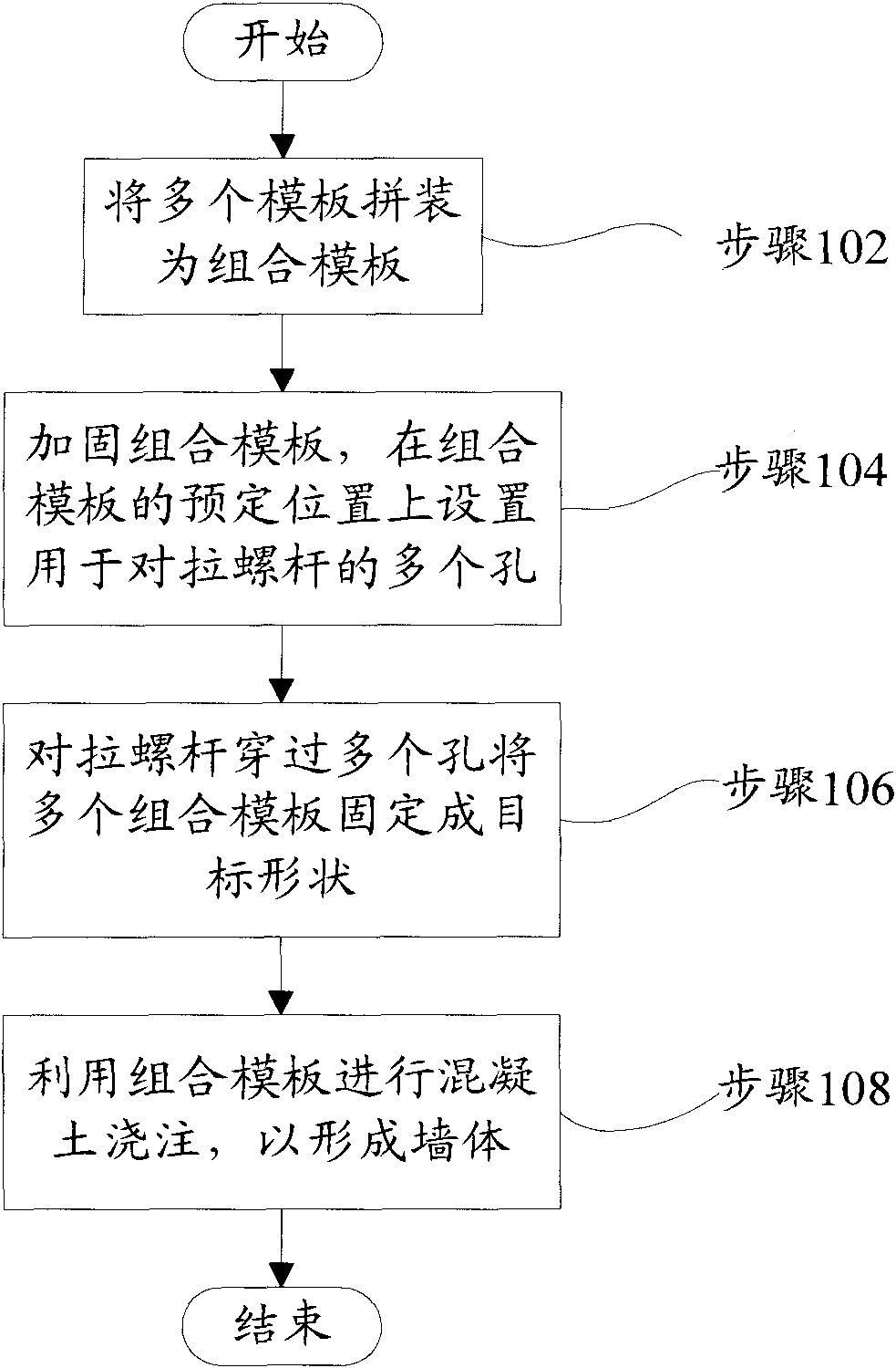

[0017] figure 1 is a flow chart of the method for building a wall according to the present invention.

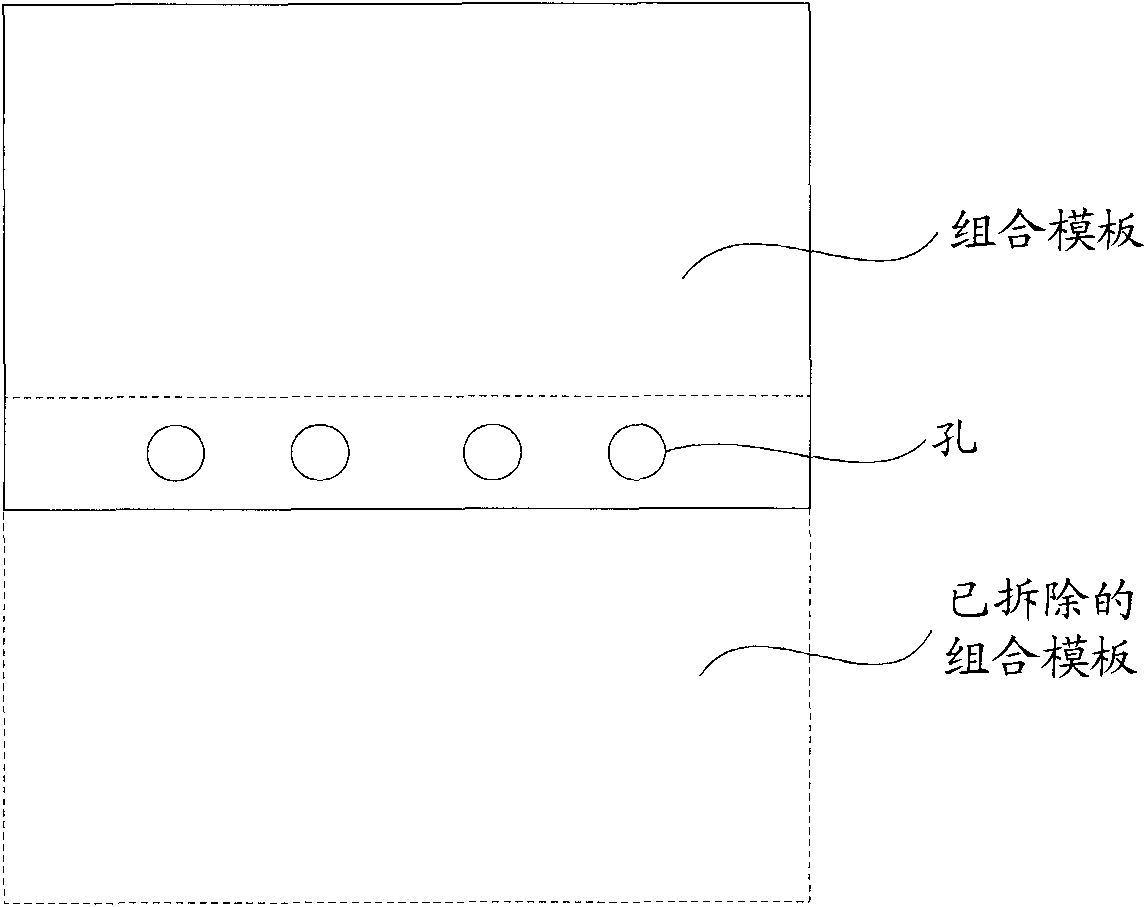

[0018] like figure 1 As shown, the present invention provides a method for building a wall, including: step 102, assembling a plurality of templates into a composite template; step 104, reinforcing the composite template, and setting a a plurality of holes in the pull screw; step 106, the pull screw passes through the plurality of holes and fixes a plurality of the combined formwork into a target shape; and step 108, uses the combined formwork to pour concrete to Form the wall.

[0019] In the above technical solution, the strengthening of the combined formwork includes: using channel steel as the main flute and wood beams as the secondary flute to reinforce the combined formwork.

[0020] In the above technical solution, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com