Intelligent horizontal cable releasing method

A horizontal and cable reel technology, applied in program control, instrument, program control in sequence/logic controller, etc., can solve problems such as data cannot be saved, human resources are consumed, and operation is inconvenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

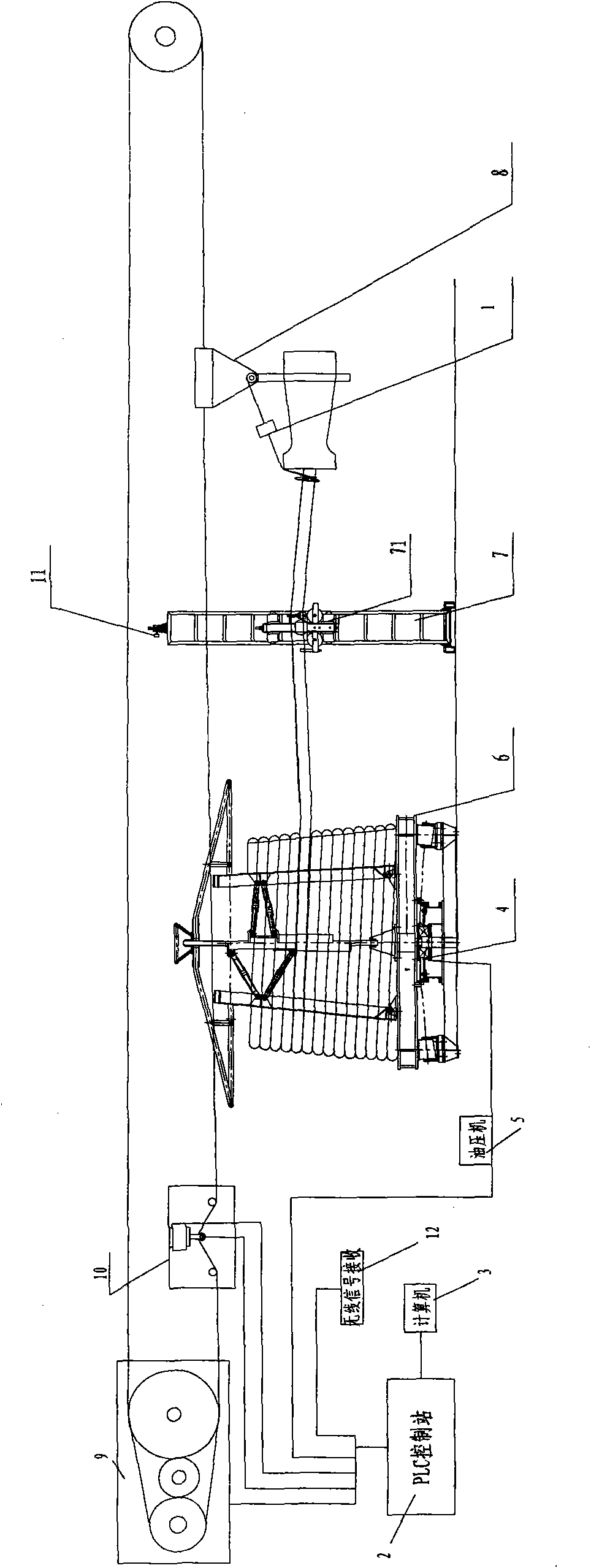

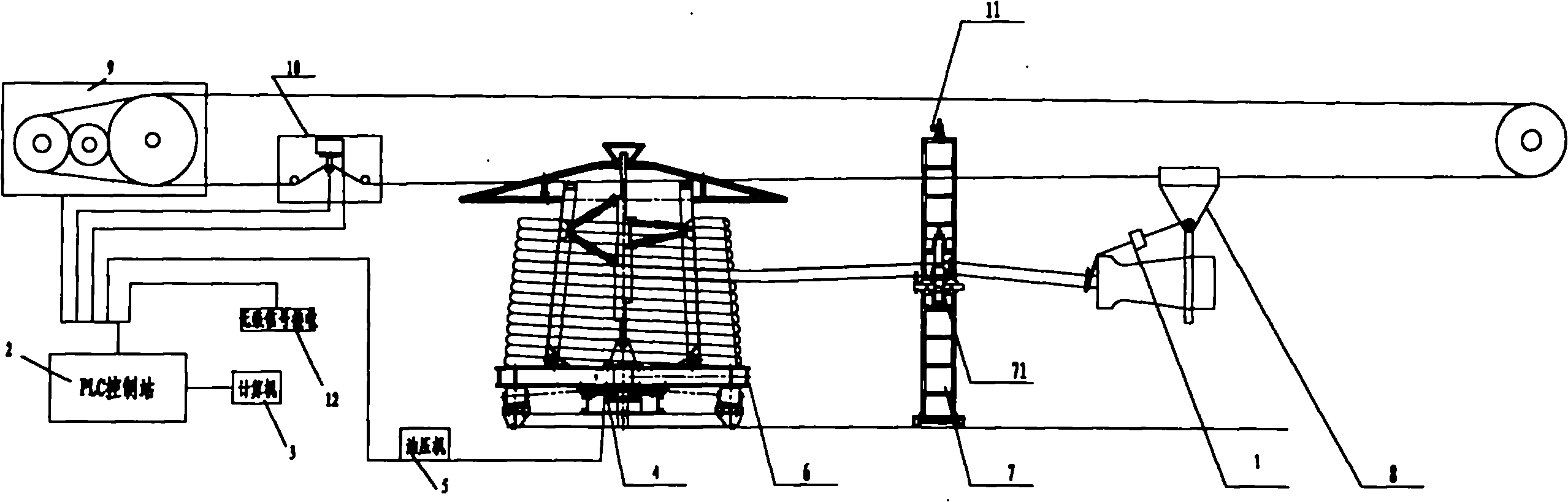

[0020] Such as figure 1 An "intelligent horizontal cable-laying method" for the main cable of a suspension bridge, using PLC control, can display, save, and control various data during the cable-laying process. Realization: automatic and manual cable release, release cable according to the set speed and resistance, automatically adjust and record the height of the guide wheel, emergency stop, measure and record the length and speed of cable release, display and record the motor current and oil pressure of the hydraulic machine , oil temperature.

[0021] Monitor the traction force, counter-pull force and traction speed during the unwinding process of the suspension cable strands, and digitally display and save the key data, and make a graph. The traction force is provided by the tension sensor 1, and is input to the PLC console 2 through wireless transmission, and finally input to the computer 3 for storage. The anti-pull force is provided by the friction force of the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com