Counter-pull pressure detection apparatus for a casting having a cavity with an opening in a cavity wall

A detection device and cavity wall technology, which is applied in the direction of measuring the increase and decrease rate of the fluid, and using the liquid/vacuum degree to measure the liquid tightness, etc., which can solve the problems such as the inconvenience of the pressure detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

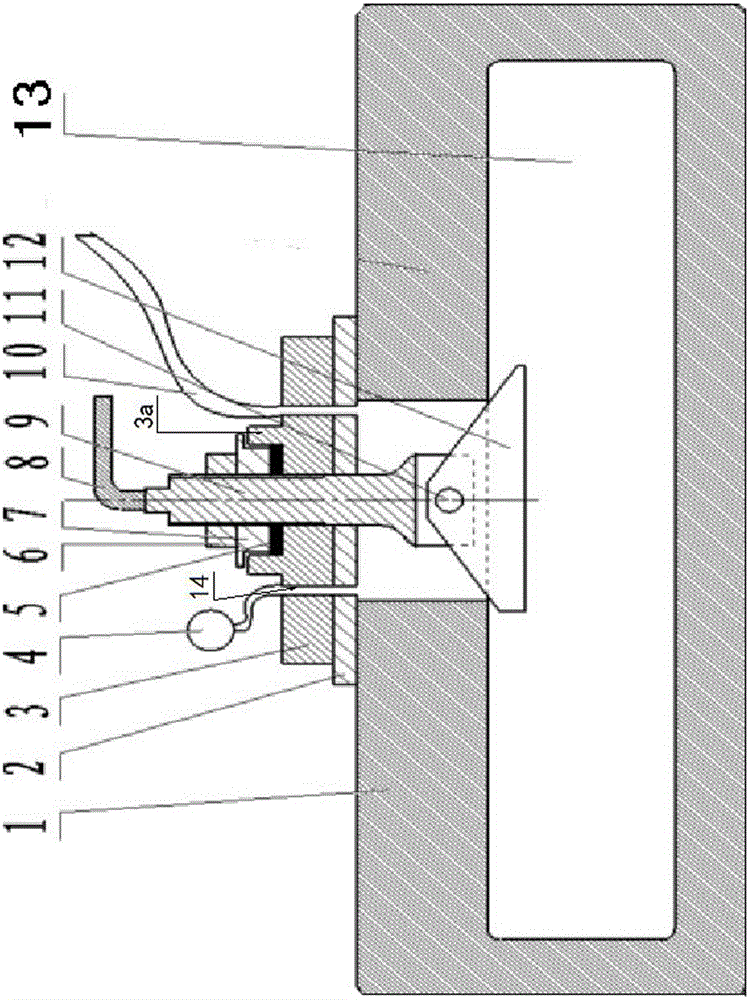

[0012] Such as figure 1 Shown is the anti-pull type pressure detection device for a casting with an opening on the cavity wall of the present invention, including an eccentric pull plate 12 arranged against the inner opening of the casting opening, and a pressing plate 3 is provided on the outer end of the opening, and the pressing plate 3 and the opening A rubber pad 2 is provided between the outer end faces, and the pressure plate 3 is provided with an inlet pipe 10 and an outlet pipe 14 communicating with the cavity 13 of the casting. It is tightened by the tension screw 9 that runs through the pressure plate 3 and the rubber pad 2. The tension screw 9 on the upper side of the pressure plate 3 is connected with a compression nut 6. The eccentric tension plate 12 is in the shape of a triangle or a trapezoid with a small top and a large bottom. 12 upper ends and the lower end of strong connecting screw rod 9 are connected through a piercing pin 11, and the eccentric pull plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com