Bracket counter pull loading pre-pressing device and tensioning pre-pressing method thereof

A technology for loading preloading and brackets, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of heavy workload, long time, high cost, etc., to save preloading costs, save preloading time, and reduce safety risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following non-limiting examples illustrate the invention.

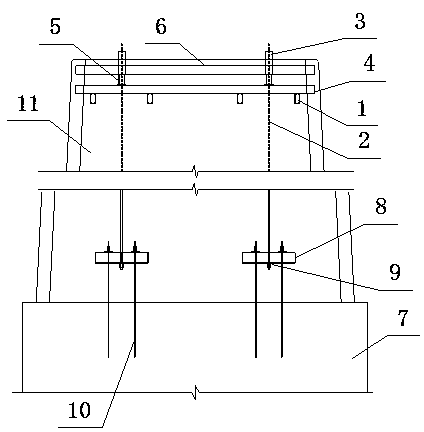

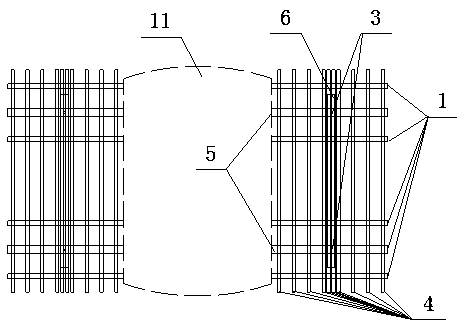

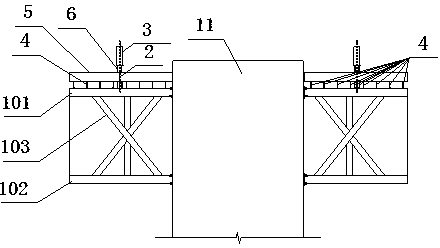

[0025] Such as Figures 1 to 5 As shown, a bracket back-pull loading preloading device consists of an upper anchor system placed on the bracket 1, a lower anchor system located below the upper anchor system, and a steel strand bundle 2 connected to the upper and lower anchor systems and tension The jack 3 is composed of the lower anchor system as the anchoring end, the upper anchor system as the tension end, and the upper anchor system consists of several distribution beams 4 placed on the top of the bracket 1, at least two reinforcing longitudinal beams 5 placed on the top of the distribution beam 4, A reinforced beam 6 placed on the top of the reinforced longitudinal beam 5, and a tension jack 3 installed on the top surface of the reinforced beam 6 at the intersection of the reinforced beam 6 and the reinforced longitudinal beam 5; Every 2 is a group of several groups of connecting columns, the double-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com