Counter-pulled type rib retaining wall of pre-stressing force cantilever

A pre-stressed, cantilever-type technology, applied in the processing of building materials, construction, artificial islands, etc., can solve the problems of poor seismic force resistance, easy damage, and poor integrity of the retaining wall, so as to reduce the side The effect of reducing the amount of deformation, enhancing the anti-collision performance, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

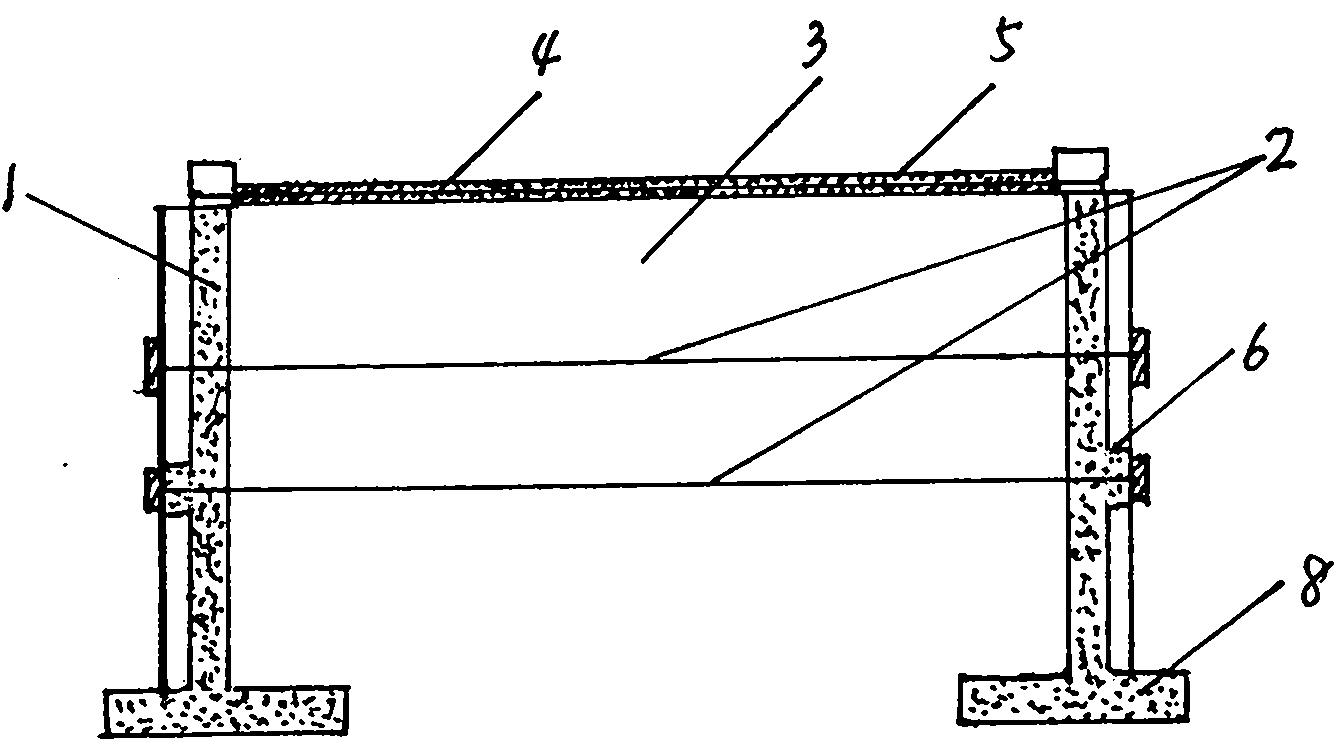

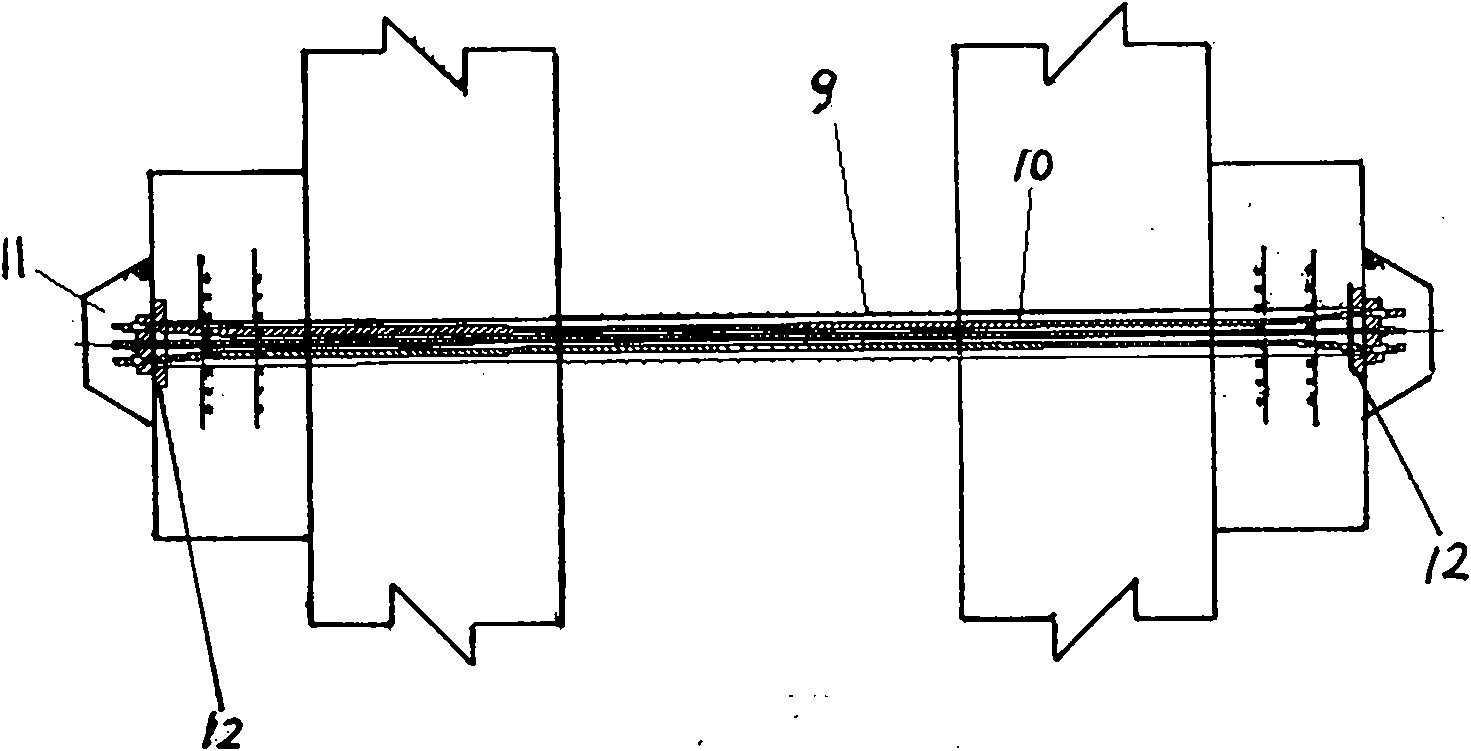

[0015] The retaining wall is composed of a cantilever reinforced concrete retaining wall 1 arranged symmetrically on both sides of the roadbed and a row of paired anchor cables 2 running through the width of the roadbed. The cross section of the retaining wall 1 is a single layer, and the retaining wall Under the body 1, there is a bottom plate 8 buried under the ground line 7, and the middle part is provided with ribs 6 for installing anchor piers 11. There are plastic sleeves 9 outside the anchor cables 2, and the anchor cables are 5 bundles of 7φ5 steel strands. There is a grouting protective layer between the plastic pipe sleeve 9 and the steel strand 10, the two ends of the anchor cable 2 are connected to the anchor plate 12 on the outside of the rib 6, and the embedded road structure is arranged on the top of the cantilever retaining wall 1 5, the embankment fill 3 is filled between the top of the ground line 7 and the cantilever retaining wall 1 and the pavement structur...

Embodiment 2

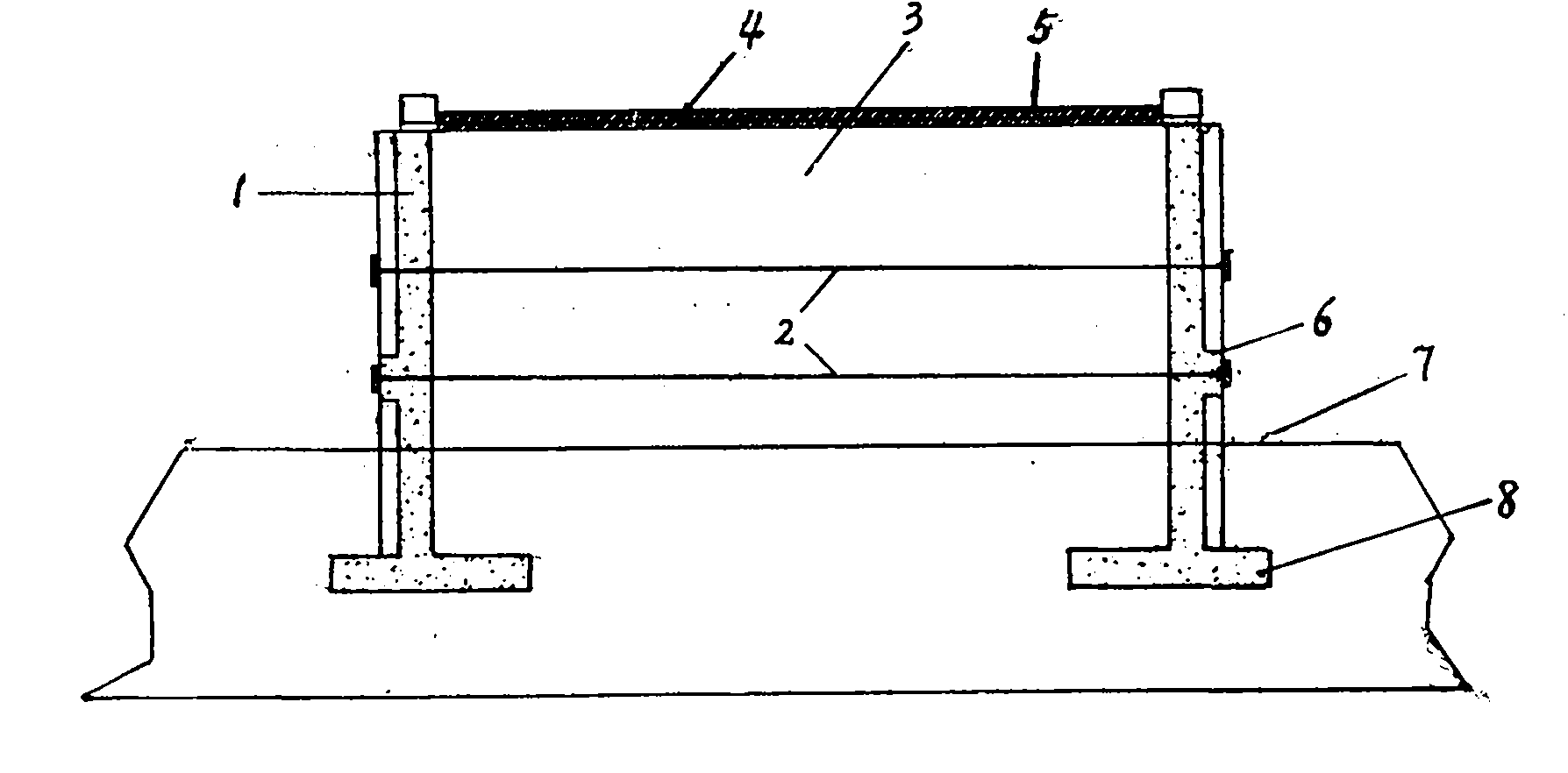

[0017] The retaining wall is composed of a cantilever reinforced concrete retaining wall 1 arranged symmetrically on both sides of the subgrade and connected with an anchor cable 2 running through the width of the subgrade. The cross section of the retaining wall 1 is stepped and has two layers, each There are two rows of opposing anchor cables 2 across the width of the subgrade. Under the retaining wall 1, there is a bottom plate 8 embedded below the ground line 7. The middle part is provided with ribs 6 for installing anchor piers 11. The outer anchor cables 2 are There are plastic sleeves 9, and the anchor cables are 5 bundles of 7φ5 steel strands 10. There is a grouting protective layer between the plastic sleeves 9 and the steel strands 10, and the two ends of the anchor cables 2 have anchors connected to the outer sides of the ribs 6. Backing plate 12, on the top of the cantilever retaining wall 1 on the upper floor, is provided with reinforcing bars 4 embedded in the pav...

Embodiment 3

[0019] A highway has a section of clay roadbed with a height of 9.0m. A stepped double-layer cantilever retaining wall is adopted.

[0020] The lower cantilever retaining wall 1 is 6m high, 0.5m wide, and the bottom plate 8 is 0.5m thick; the upper cantilever retaining wall 1 is 3.35-4.5m high, 0.4m wide, and the bottom plate 8 is 0.5m thick. The upper cantilever retaining wall 1 is provided with one row of tensioned prestressed anchor cables 2 penetrating the subgrade, with a longitudinal spacing of 3m, and the lower cantilever retaining wall 1 is provided with two rows of tensioned prestressed anchor cables 2 penetrating the subgrade, with a longitudinal spacing of 3m. . The prestressed tension locking values of the anchor cable 2 are 100kN, 800kN, and 800kN from top to bottom.

[0021] The part of the wall above the ground line 7 must be provided with drain holes, with a distance of 2 to 3 meters, arranged staggered up and down, left and right, and φ7.5cm PVC drain pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com