Side wall self-propelled type triangular truss and construction method thereof

A technology of triangular truss and construction method, which is applied to the connection of formwork/template/work frame, the preparation of building components on site, the processing of building materials, etc. Problems such as wrong platform, to achieve the effect of convenient construction, reduced mold running, and easy adjustment

Pending Publication Date: 2016-06-15

POWERCHINA RAILWAY CONSTR +1

View PDF7 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Taking the subway station as an example, in the concrete construction of the side wall of the main structure of the urban subway station, when the currently widely used steel pipe support horizontally supports the for

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Login to View More

Abstract

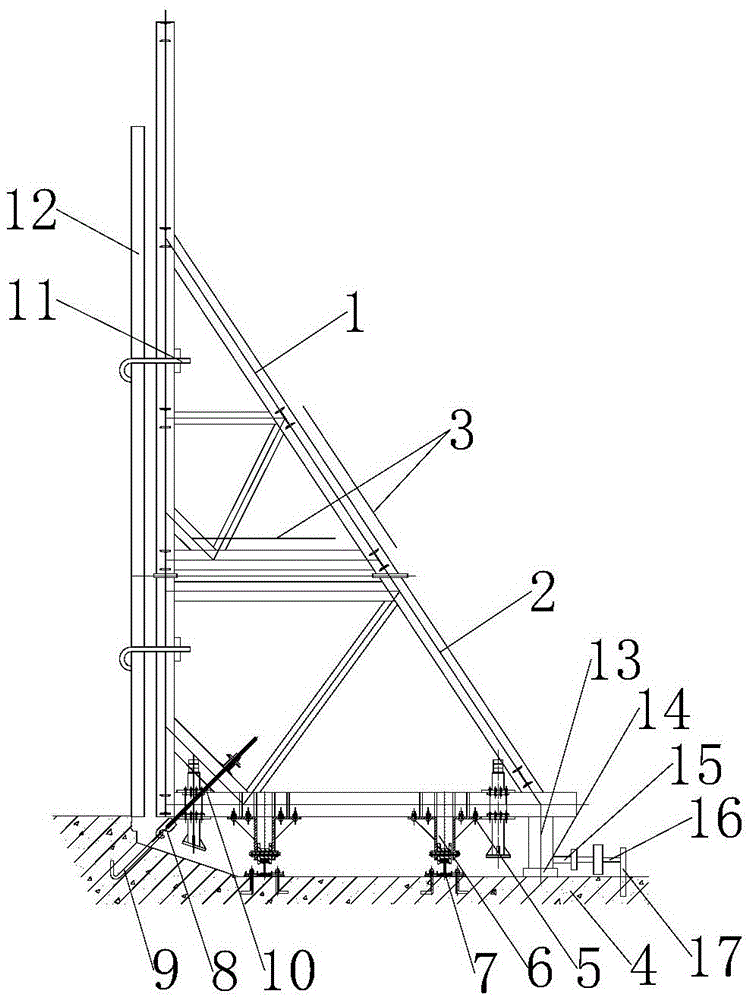

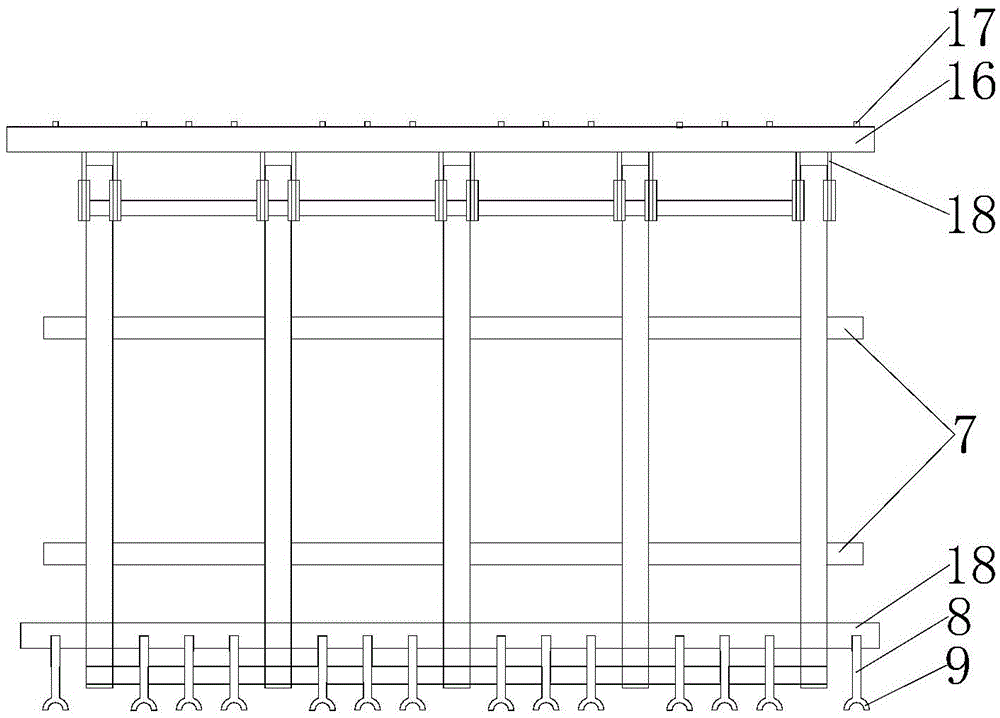

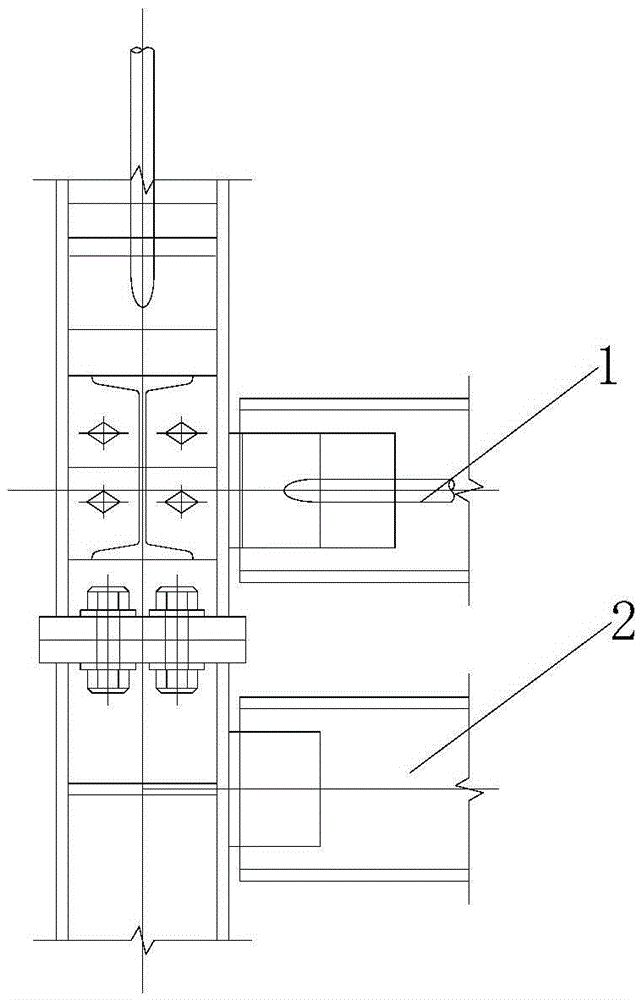

The invention discloses a side wall self-propelled type triangular truss. The side face of the triangular truss is connected with an all-steel large formwork through a back arris device, the triangular truss comprises an upper segment and a lower segment, the upper segment of the triangular truss is fixed above the lower segment of the triangular truss, and a counter pull system and an anti-thrust system are respectively fixed on the triangular truss. The construction method of the triangular truss comprises steps of preparation for construction, segmentation for construction side walls, processing of side wall formwork and side wall bracket formwork, installation of embedded parts and formwork installation. The triangular truss disclosed by the invention reduces the requirement for accuracy in installation of soleplate anchoring parts and is convenient in construction, and the construction method has the advantages of well arranged operation, high work efficiency, cost saving and the like.

Description

technical field [0001] The invention is applicable to the construction of side walls in narrow spaces of tall buildings such as subways, railways, and factory buildings, and relates to a shaped steel formwork, in particular to a side wall self-propelled triangular truss and a construction method thereof. Background technique [0002] Compared with the general side wall construction, the side walls of subway stations, railway stations and factory buildings have the characteristics of large height and long length. Taking the subway station as an example, in the concrete construction of the side wall of the main structure of the urban subway station, when the currently widely used steel pipe support horizontally supports the formwork system for construction, it is very easy for the horizontal support of the steel pipe to be not firmly aligned to the top, resulting in mold runout and limit invasion. , Wrong Taiwan and other quality defects. [0003] The above deficiencies are w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04G17/14E04G21/00

CPCE04G17/14E04G21/00

Inventor 任立志朱瑞喜唐勇胡德华张健刘永波王建辉鲁志刚

Owner POWERCHINA RAILWAY CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com