Counter-pulling wall connecting component

A technology of connecting wall parts and wall parts, which is applied to the accessories of scaffolding, building structure support, building structure support, etc., can solve problems such as wall damage, wall thickness limitation, and hidden safety hazards, so as to ensure turnover and increase The effect of improving reliability and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, in conjunction with the accompanying drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

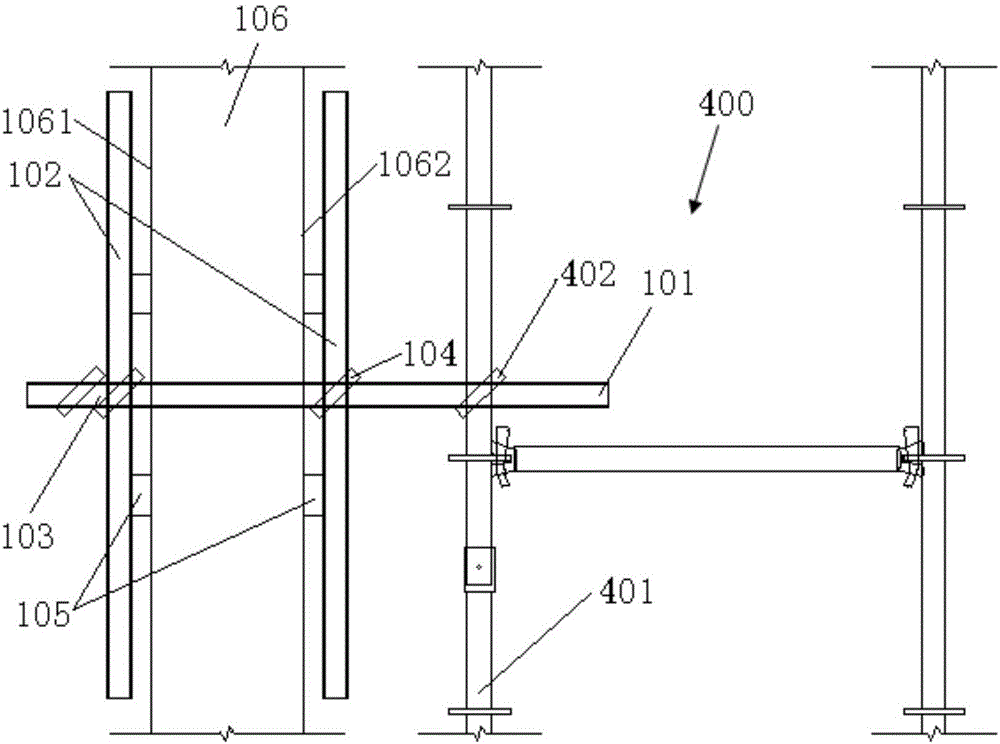

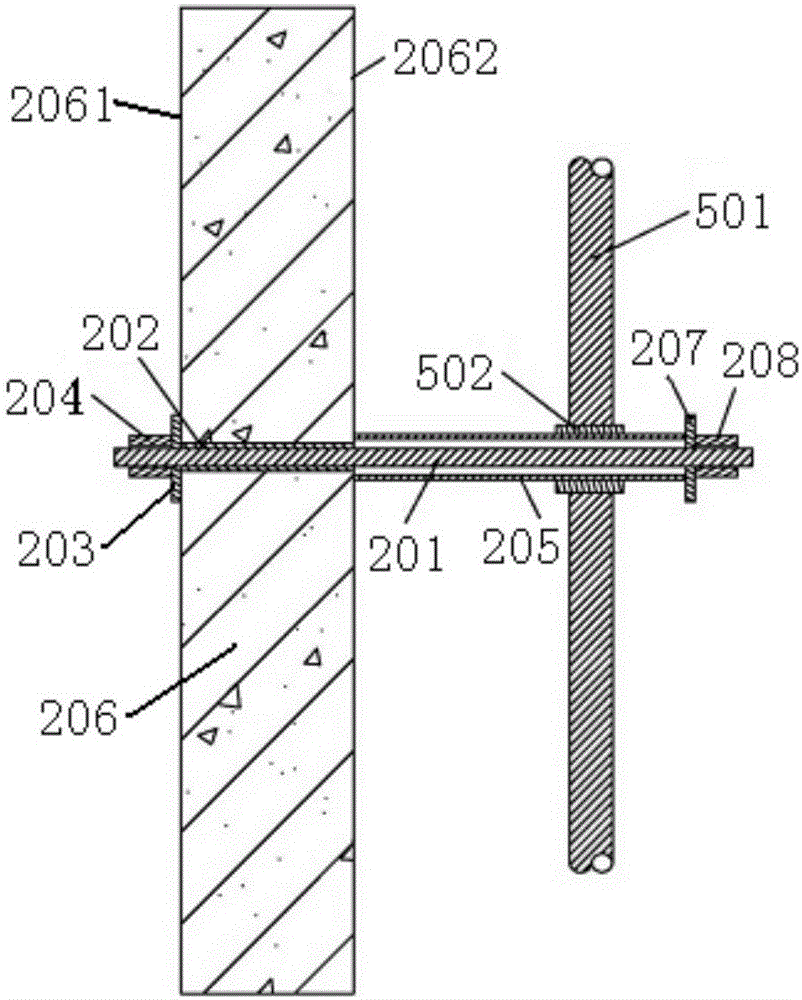

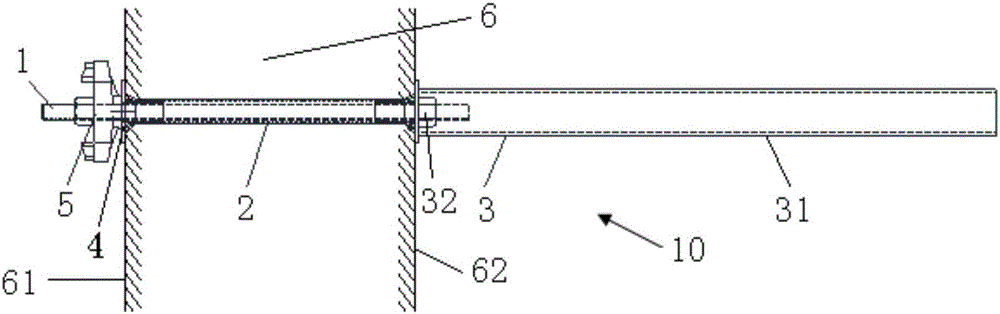

[0029] Such as image 3 with 4 Shown is a wall connecting piece 10 according to a preferred embodiment of the present invention. The wall connecting piece 10 includes a pull screw 1 which has external threads and whose two ends protrude from the inner wall surface 61 and the outer wall of the wall body 6 respectively. surface 62, and are respectively fixed at the two side walls by fastening devices; a pre-embedded pipe 2 is sleeved on the outer peripheral wall of the pull screw 1 between the inner wall surface 61 and the outer wall surface 62; a connecting wall pipe One end of the assembly 3 is fixedly connected to the part of the pull screw 1 protruding from the outer wall surface 62 , and vertically abuts against the outer wall surface 62 of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com