Recycling type steel structure slope protection pile component and installing and disassembling methods thereof

A technology for slope protection piles and components, which is used in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of material waste and unrecyclable steel cages, and achieve the effect of reducing costs, being easy to lower and hanging, and ensuring the use of turnover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

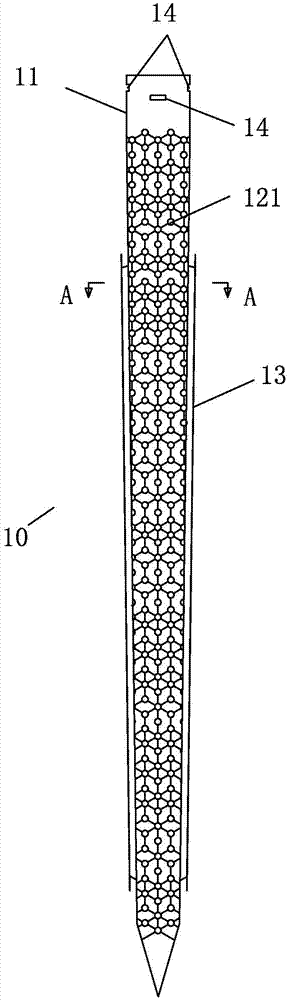

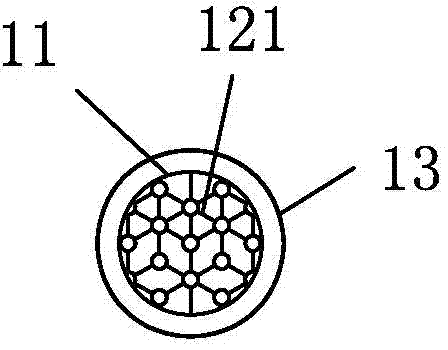

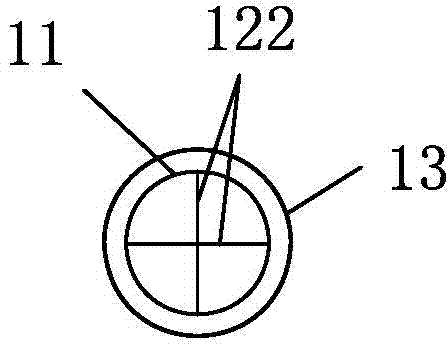

[0033] like Figure 1 to Figure 3 As shown, the circumferential type steel structure slope protection pile member 10 of the present invention includes an inverted cone-shaped hollow steel pipe 11, which is thick at the top and thin at the bottom. , the steel pipe 11 is welded with a steel filler for enhancing the horizontal rigidity, the steel filler is used to enhance the horizontal rigidity of the steel pipe 11, and together with the steel pipe 11 bear the horizontal force of the soil behind the slope protection pile, the steel pipe The top of 11 is provided with at least one pair of through holes 14, and each pair of through holes 14 is used to penetrate a steel plate, and the outer wall of the steel pipe 11 is bound with a circle of steel mesh 13, and the steel mesh 13 is used to improve the steel pipe 11 and the pile hole 20. The friction between the inner concrete 30 is used to firmly fix the steel pipe 11 in the concrete 30 .

[0034] In the actual design, the steel fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com