Method for obtaining gap between rolling mill bearing seat and housing frame in real time

A technology of real-time acquisition and bearing housing, which is applied in the direction of metal rolling, metal rolling, length measuring devices, etc., can solve the problems that affect the horizontal stiffness of the rolling mill, cannot guarantee the real-time performance of gap control, and cannot be observed in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

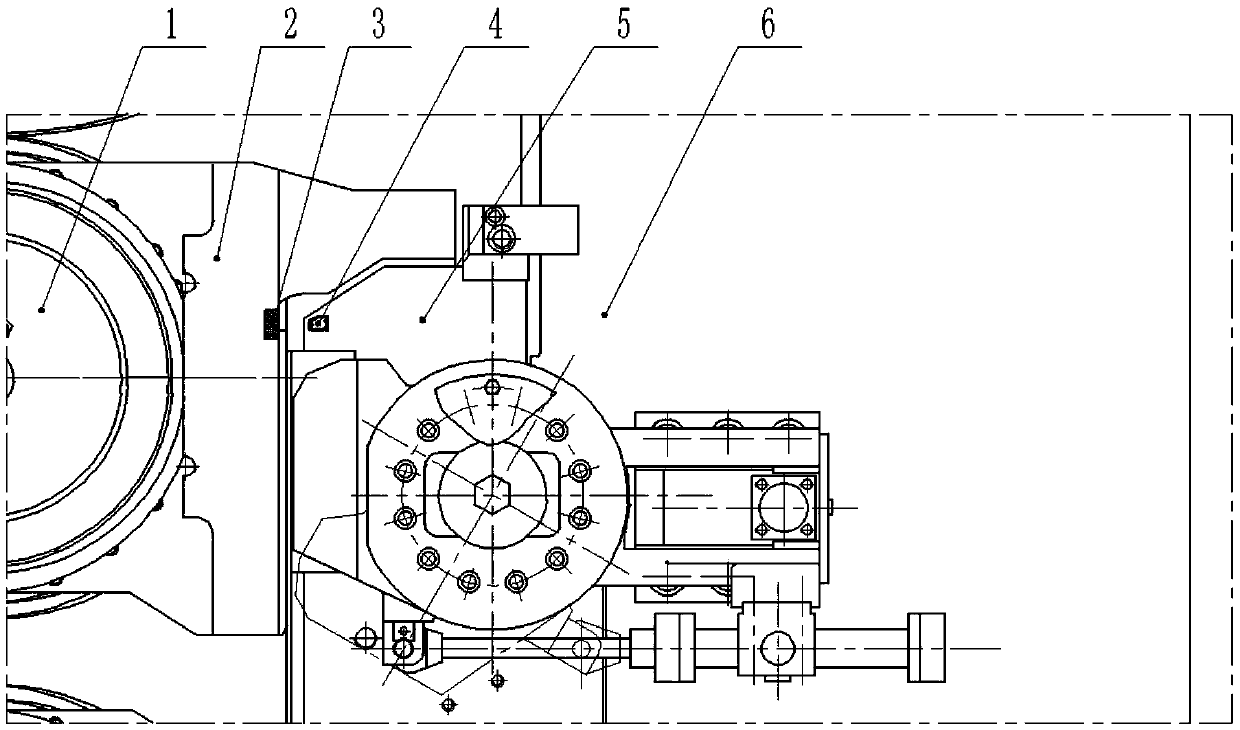

[0062] Such as figure 1 As shown, the present invention provides a method for obtaining the gap between the rolling mill chock and the arch in real time, which includes a work roll body 1, a work roll chock 2, a measuring point 3, a displacement sensor 4, and a balance bending cylinder block 5 and archway 6;

[0063] It includes the following steps:

[0064] S1: Adjust the gap between the work roll chock and the arch of the rolling mill to within the allowable range of the initial gap control standard, and the allowable range of the initial gap control standard is the first preset value;

[0065] Specifically, the allowable range of the original control standard for the gap between the work roll bearing housing 2 and the archway 6 of the 120mm experimental rolling mill is reduced from 0.02mm to 0.05mm to 0.01mm to 0.03mm;

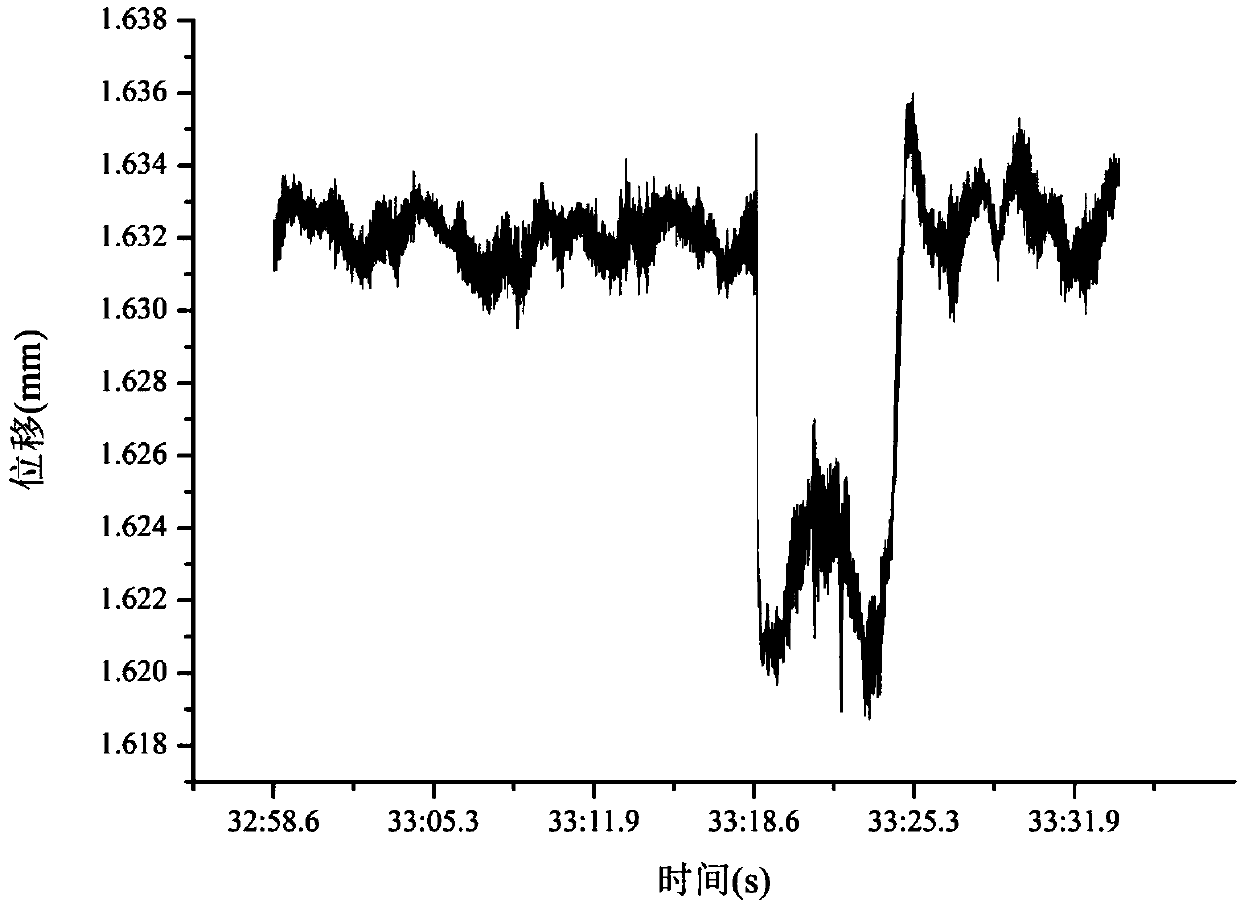

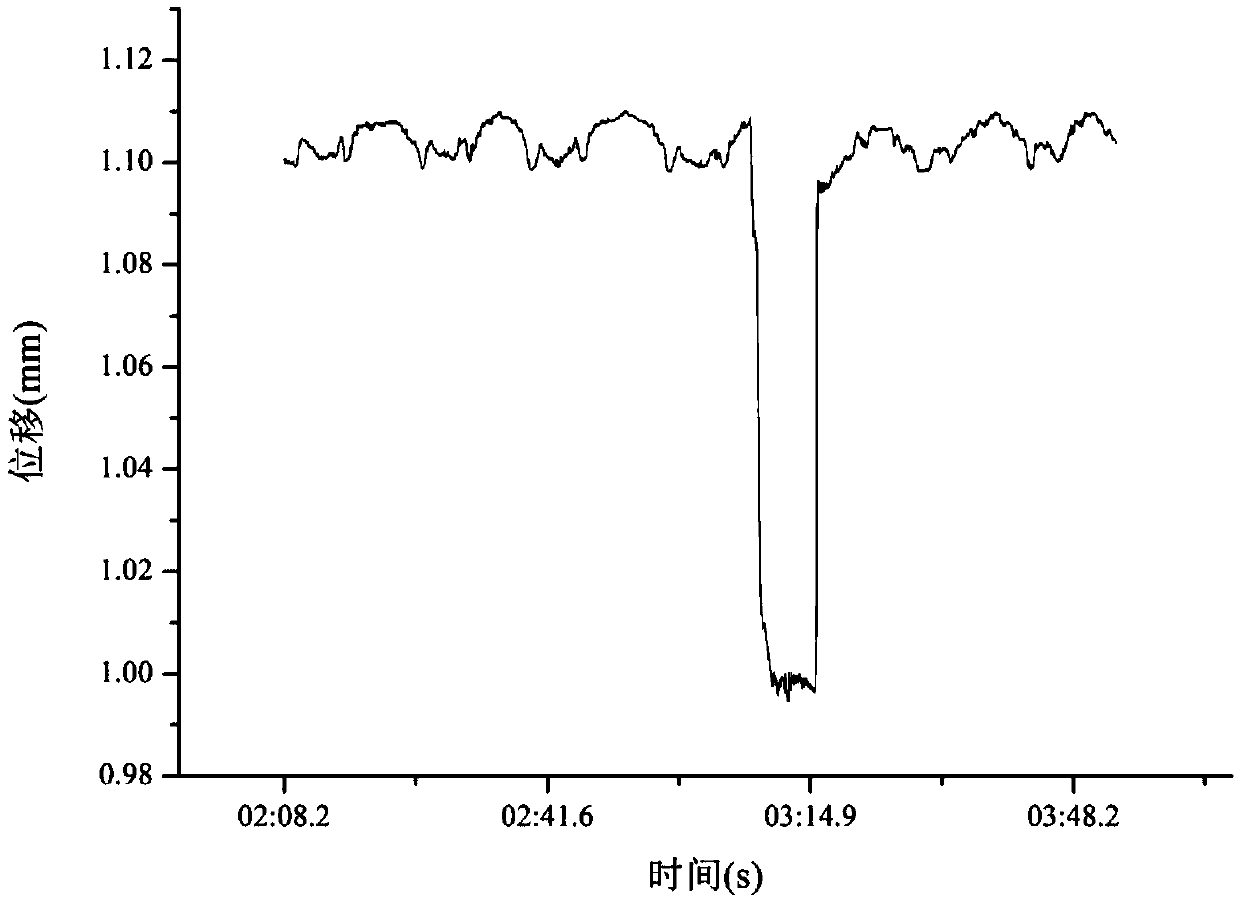

[0066] S2: Set a displacement sensor 4 at the position corresponding to the balance roll bending cylinder block 5 on the exit side of the rolling mill an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com