Furniture door hinge durability test device

A detection device and durability technology, which is applied in the detection field, can solve problems such as inconsistent switch actions, affecting the full operation of the buffer function, and inaccurate test results, achieving high reliability, easy operation, and reducing adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below in conjunction with embodiment.

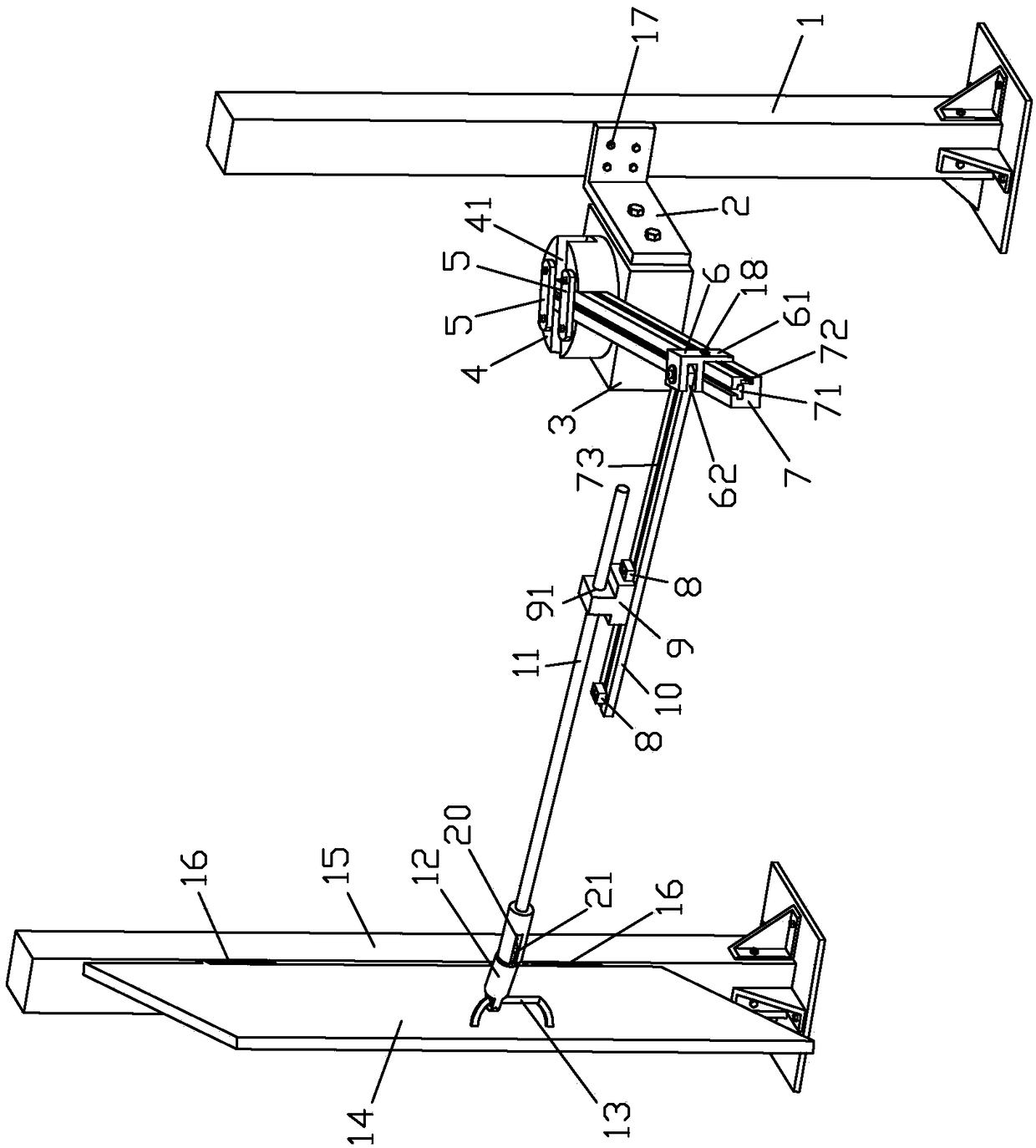

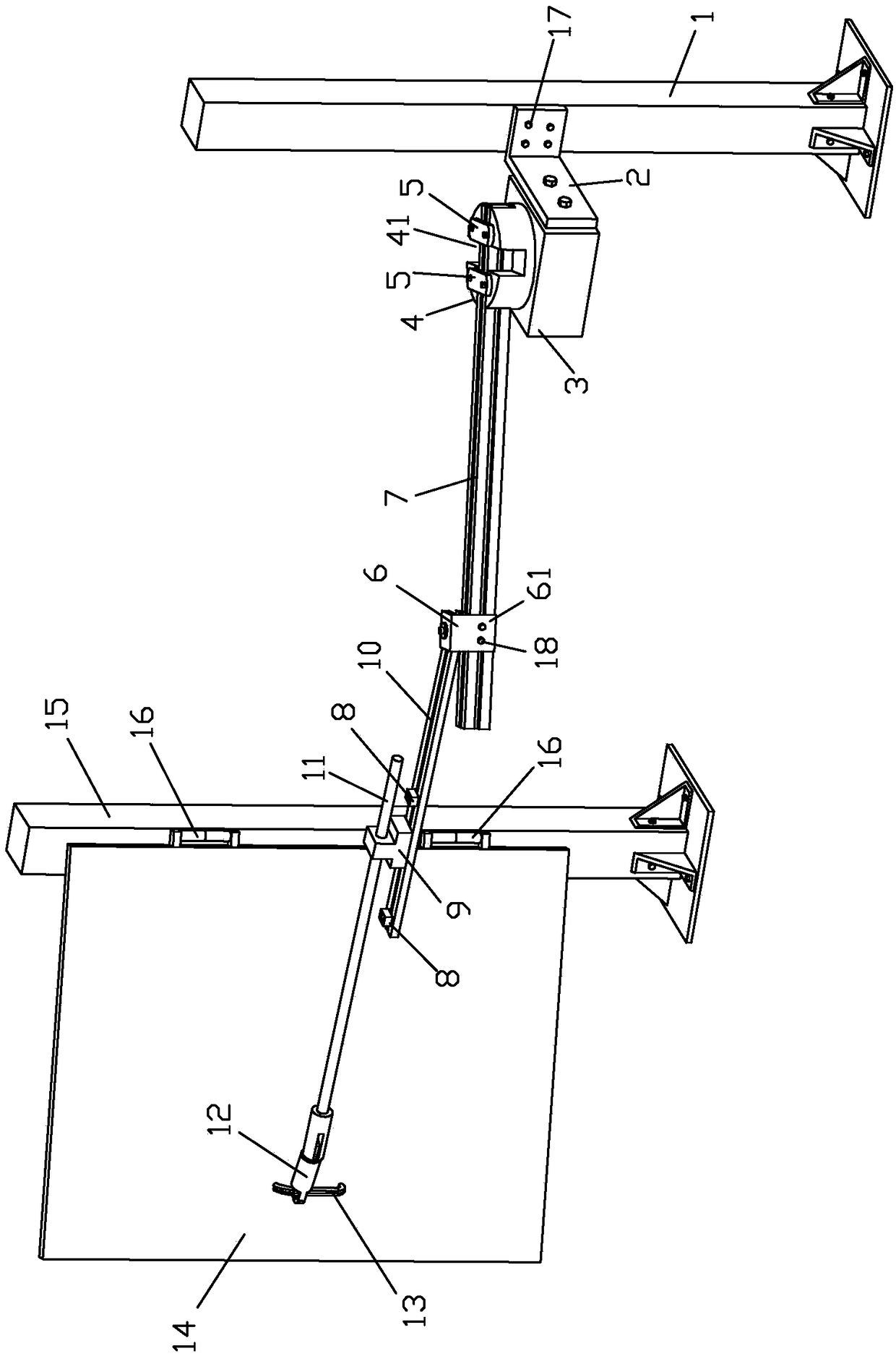

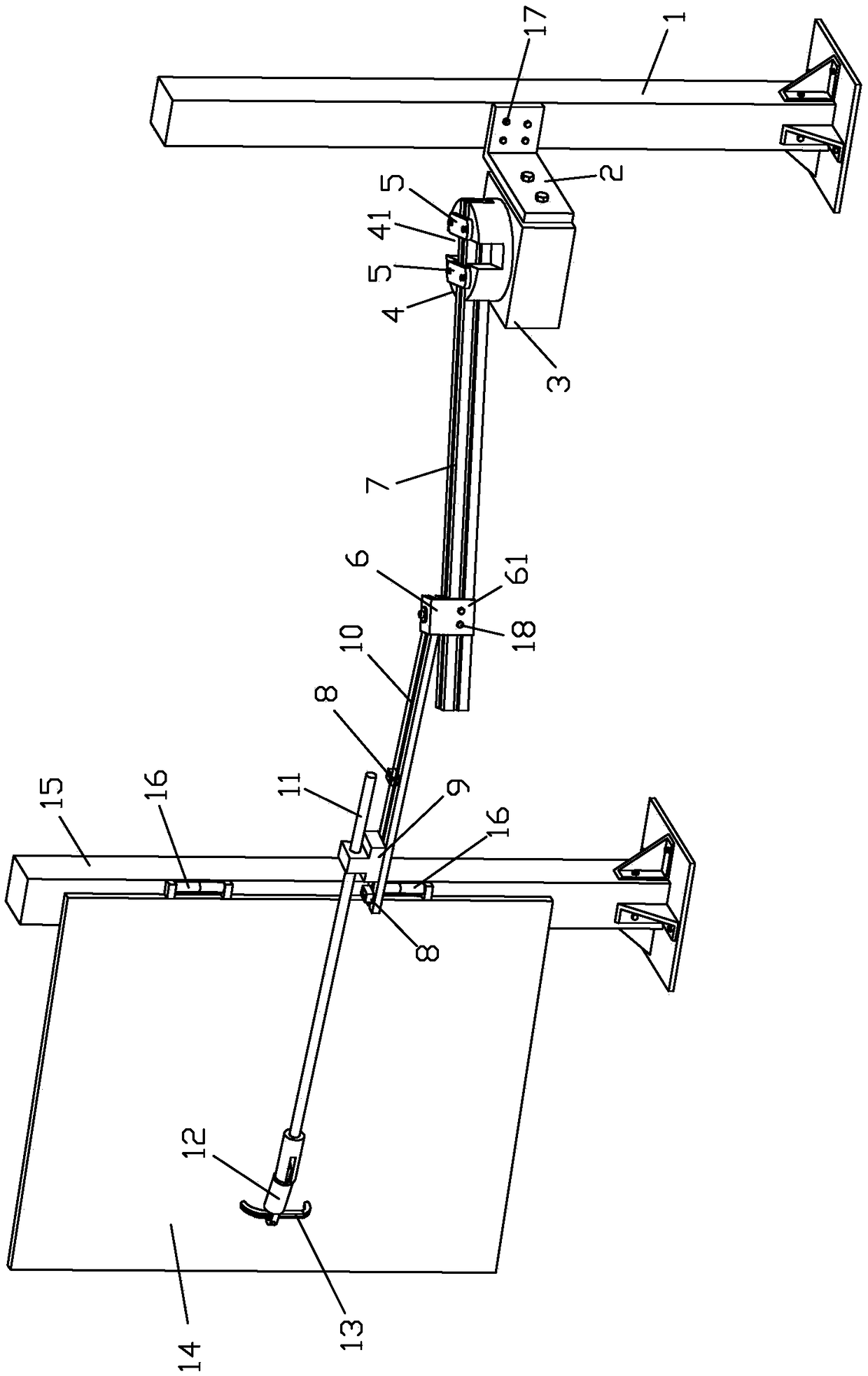

[0028] Such as figure 1 A furniture door hinge durability testing device is shown, which includes a fixed frame 1, a servo motor 3, a swing rod 7, an adjustment block 6, a guide rod 10, a slider 9, a connecting rod 11, a connecting head 12, and a detection device. Door panel 14 and door hinge mounting column 15.

[0029] The fixed frame 1 is a vertical column. The fixed frame 1 can be fixed on the ground or other installation planes. The motor mounting base 2 is fixedly installed on the fixed frame 1 through the fixing bolts 17. The servo motor 3 is installed on the motor mounting base 2. .

[0030] The swing rod 7 is connected with the output shaft of the servo motor, and the servo motor drives the swing rod to swing horizontally. The other end of the swing rod 7 is an exposed end that protrudes freely. It can slide along the length direction of the swing rod 7 , and a first locking b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com