Height adjusting spherical support

A spherical bearing and height adjustment technology, which is applied in bridge materials, buildings, bridge construction, etc., can solve the problems of affecting the smoothness of the line, long operation period of height adjustment, and high construction cost, so as to improve safety and reliability and facilitate the later stage Effects of maintenance and maintenance, ease of processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

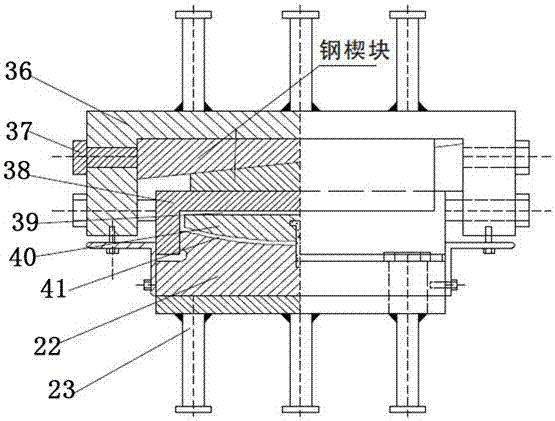

[0053] Such as Figure 7 , 8 As shown, the artificial height adjustment process of a spherical bearing is as follows: when the bridge deck height monitored by the bridge deck height monitoring system 14 reaches the height adjustment, the vertical height adjustment amount of the bearing is first set, and then the power is manually started. The source controls the vertical pushing device 11 to lift the lower seat plate 6 to a preset height (slightly 1mm higher), and completes the adjustment of the vertical height of the upper structure of the support. Manually start both sides horizontally to pushing device 13 again, adjust wedge-shaped block 9 to setting horizontal position; Then control the vertical jack in the vertical pushing device 11 of the control system to carry out jacking operation, make step block 7 drop to wedge-shaped block 9 completely Then unload the vertical force of the control system vertical thrusting device 11, and the vertical adjustment of the support is c...

Embodiment 2

[0055] Such as Figure 7 , 8 As shown, a semi-automatic height adjustment process of the height adjustment spherical bearing is: when the bridge deck height monitored by the bridge deck height monitoring system 14 reaches the height adjustment, the power source and control system are artificially installed for the height adjustment spherical bearing, Both the vertical pushing device 11 and the horizontal pushing device 13 are connected with the control system. First, set the vertical height adjustment of the support. After confirmation, start the vertical pushing device 11 of the control system, and lift the lower seat plate 6 to the predetermined level. Set the height (slightly 1mm higher) to complete the adjustment of the vertical height of the upper structure of the support. Then start the horizontal pushing device 13 on both sides of the control system, and adjust the wedge block 9 to the set horizontal position; 9, then unload the vertical power of the control system ve...

Embodiment 3

[0057] Such as Figure 7 , 8 As shown, a fully automatic height adjustment process of the height adjustment spherical bearing is as follows: when the bridge deck height monitored by the bridge deck height monitoring system 14 reaches the height that needs to be adjusted, the control system first sets the vertical height of the bearing according to the collected bridge deck information. Then the control system activates the vertical pushing device 11 to lift the lower seat plate 6 to the preset height (slightly 1mm higher), and completes the adjustment of the vertical height of the upper structure of the support. The control system starts the horizontal pushing devices 13 on both sides again, and adjusts the wedge-shaped block 9 to the set horizontal position; On block 9, unload control system vertical pushing device 11 vertical force then, and support vertically heightens and finishes. In this process, all operations are completed by the control system, which can remotely jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com