Pipeline counter-pulling and repairing device and repairing method thereof

A repair method and pipeline technology, applied to pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of high construction cost and low construction efficiency, avoid secondary damage, improve efficiency, and improve pipeline repair efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

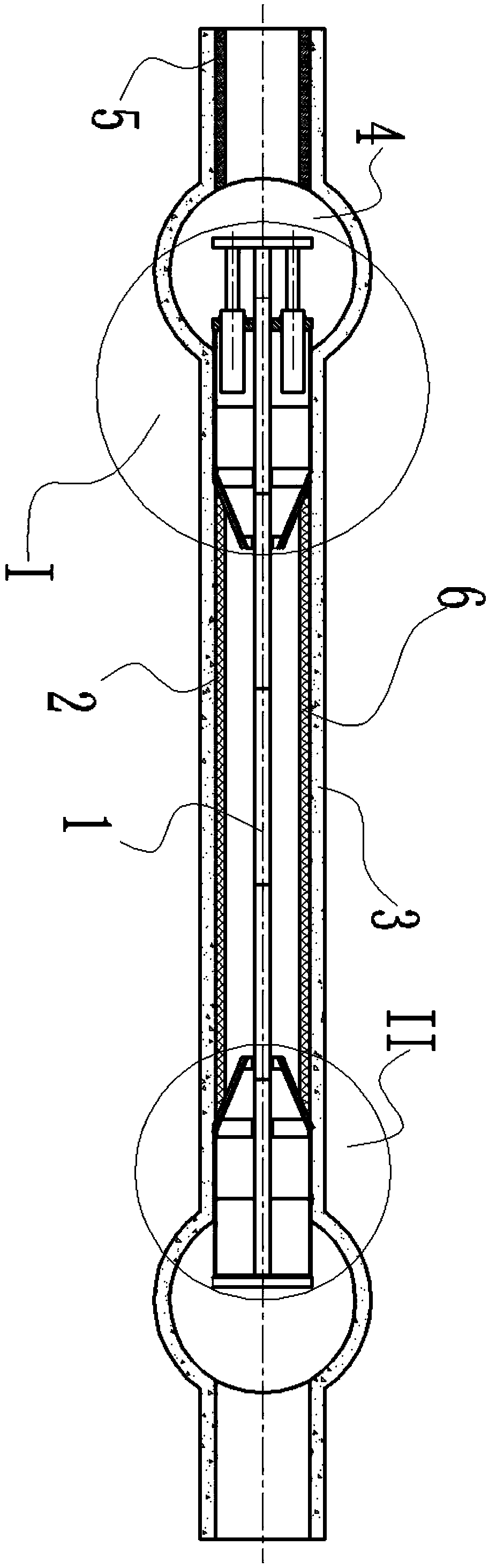

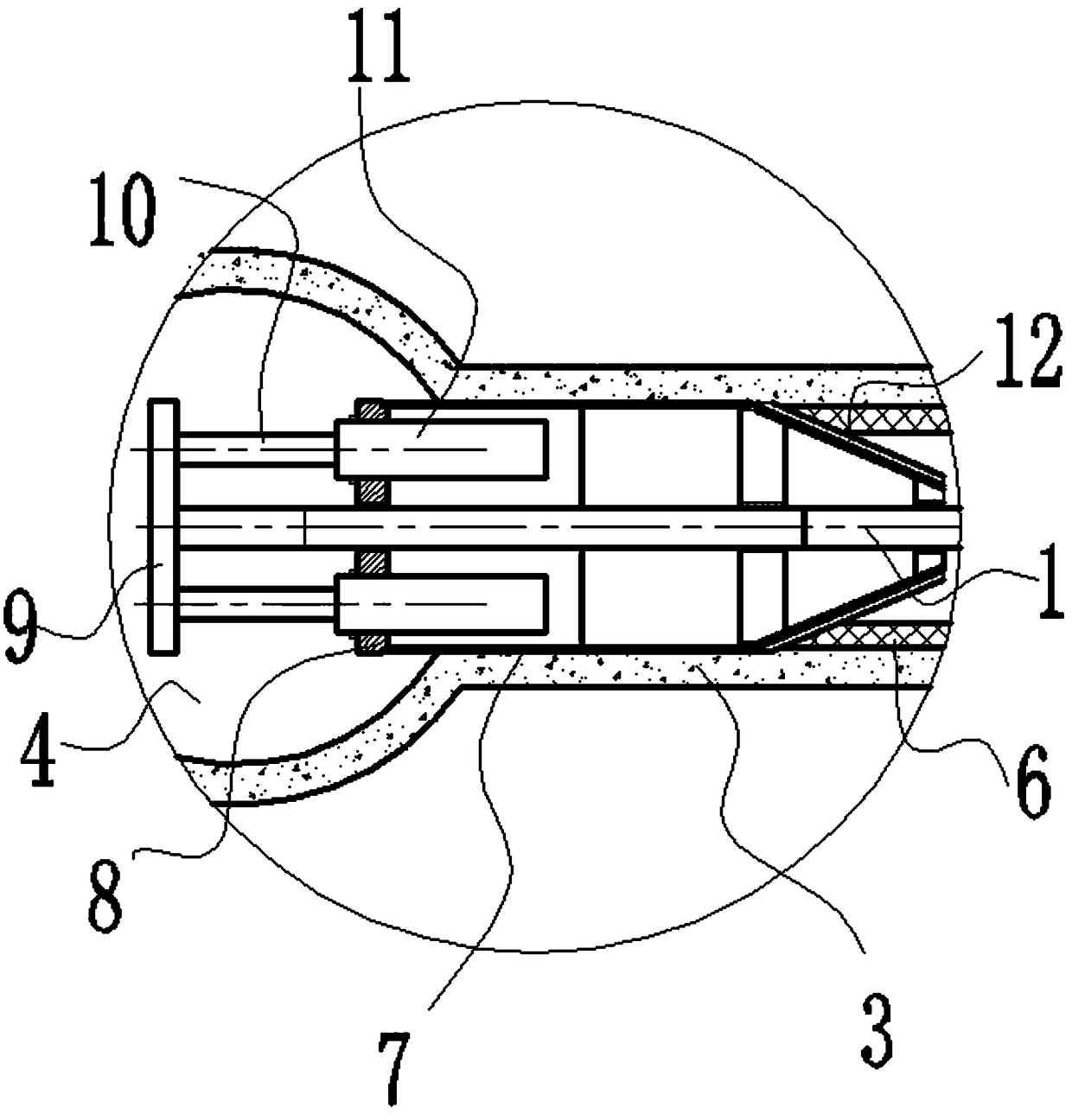

[0038] Such as figure 1 , figure 2 , image 3 As shown, the first repairing device includes a top plate 9, a first clamping plate 8, an oil cylinder 11, and a first advancing cutterhead unit 12, and the second repairing device includes a second clamping plate 13 and a second advancing cutterhead unit 14. The top plate 9 and the second splint 13 are connected and fixed by the pull rod 1; the cylinder block of the oil cylinder 11 is fixed on the first splint 8, and the piston rod 10 of the oil cylinder is fixedly connected with the top plate 9; The first splint 8 drives the steel mold 7 to advance, and the steel mold 7 pushes the first advancing cutterhead unit 12 ; the second splint 13 drives the second advancing cutterhead unit 14 to advance. Wherein, in order to put the pull rod better, one end of the pull rod is detachably connected to the top plate, and the other end of the pull rod is detachably connected to the second splint.

[0039] It should be noted that, in order...

Embodiment 2

[0052] The difference from Embodiment 1 is that the first repairing device and the second repairing device are arranged symmetrically, and the movement state of the oil cylinder is opposite to that of the second oil cylinder.

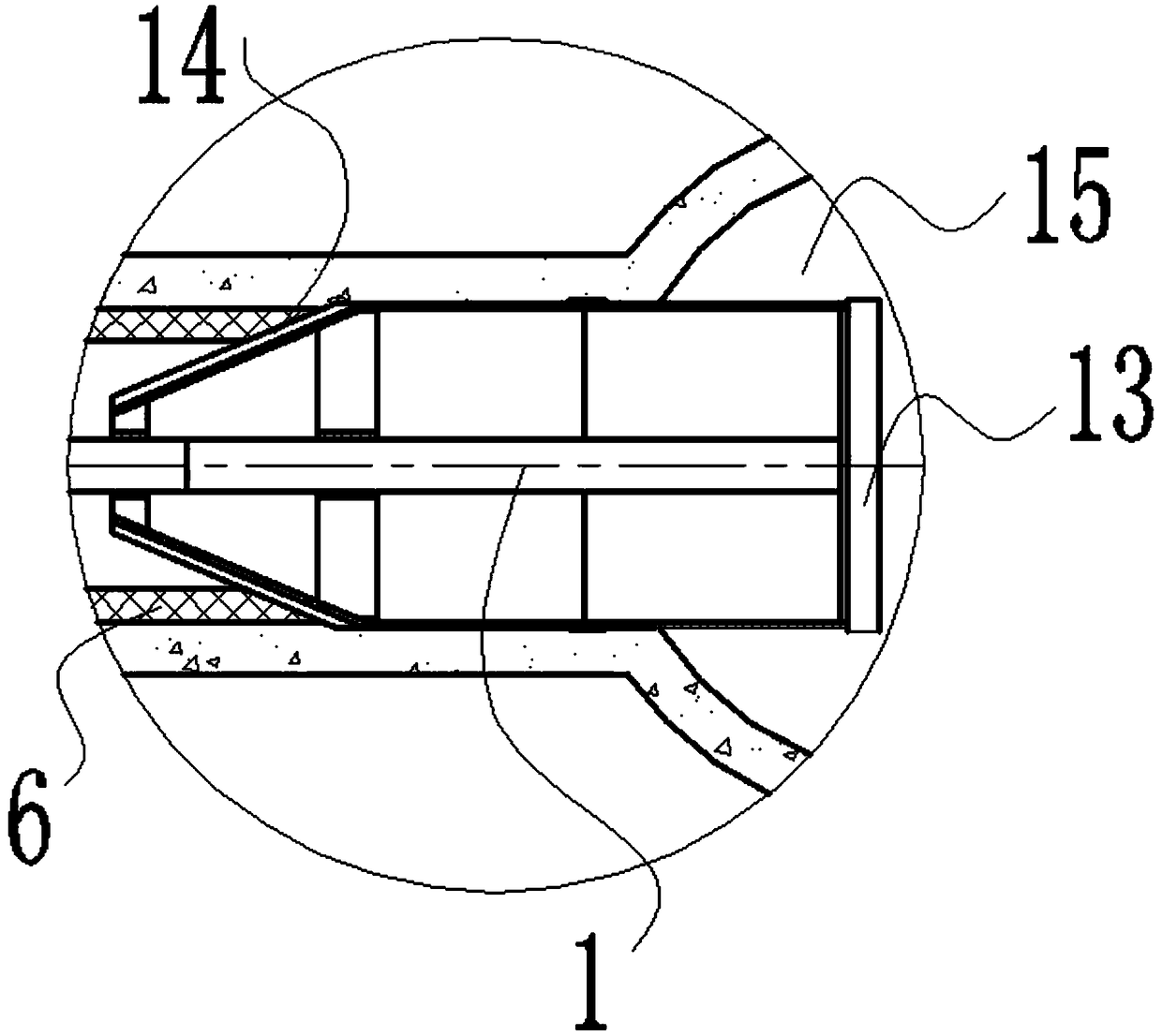

[0053] Such as Figure 4 As shown, the second repair device also includes a second oil cylinder and a second top plate, the cylinder body of the second oil cylinder is fixed on the second splint, and the piston rod of the second oil cylinder is fixed on the second On the top board (not marked in the figure), the second top board is detachably connected to the pull rod.

[0054] The use of oil cylinders on both sides can effectively prevent the oil cylinder on one side from being unusable due to failure, while the oil cylinder on the other side can still be used, which effectively improves the construction efficiency and reduces the impact of construction equipment failure on the construction process. In addition, the use of oil cylinders on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com