Steel frame formwork assembly

A steel frame and formwork technology, which is applied to the joints of formwork/formwork/work frame, formwork/formwork/work frame, and on-site preparation of building components. It can solve problems such as poor strength and achieve convenient operation. Easy operation and specification, fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

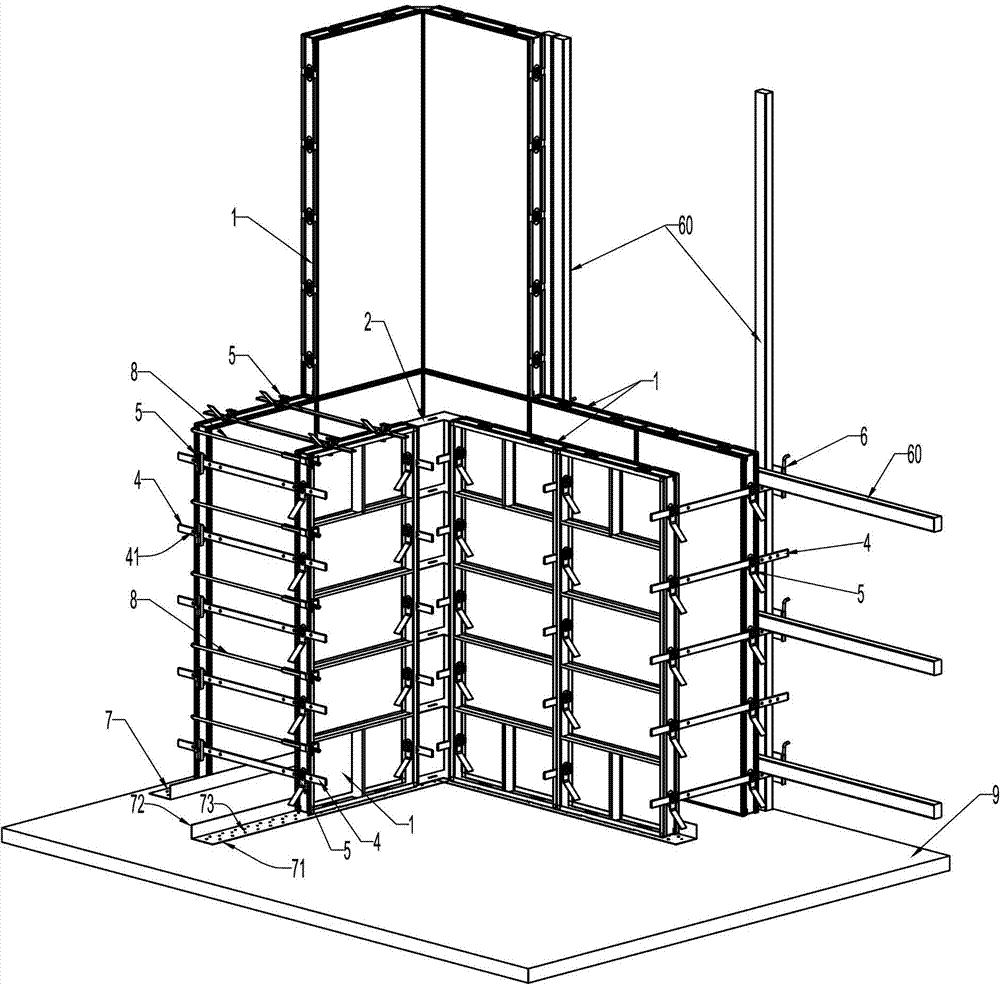

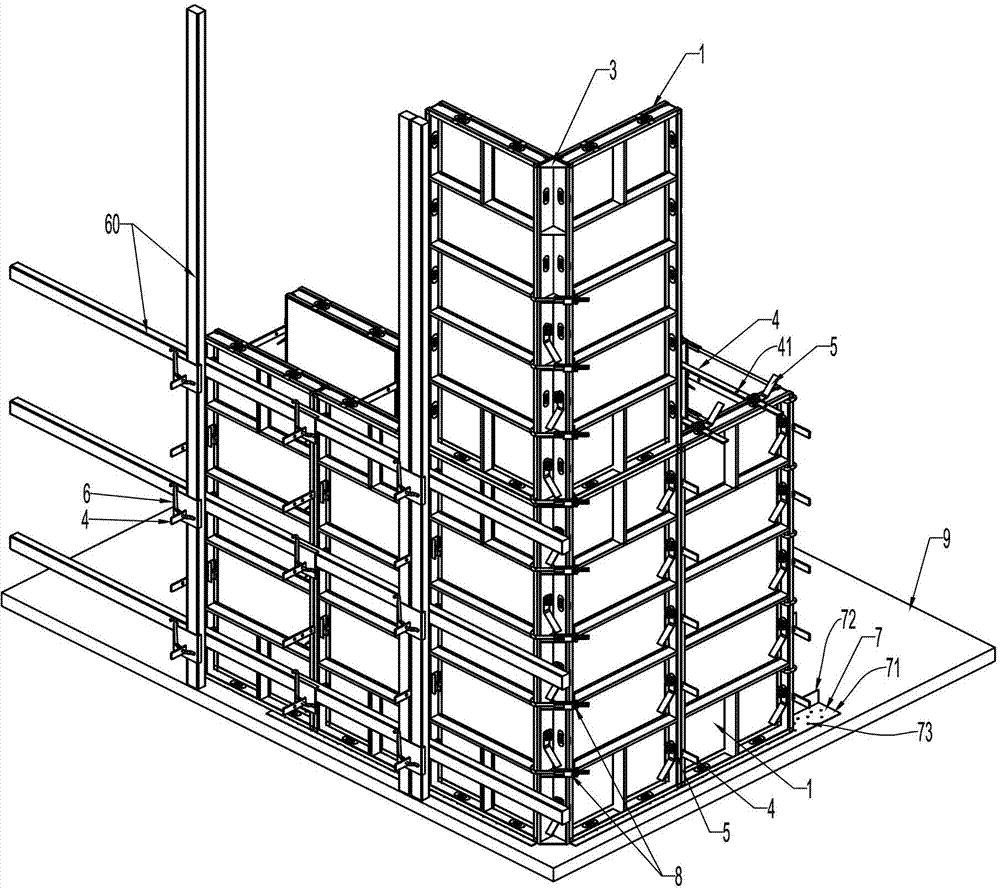

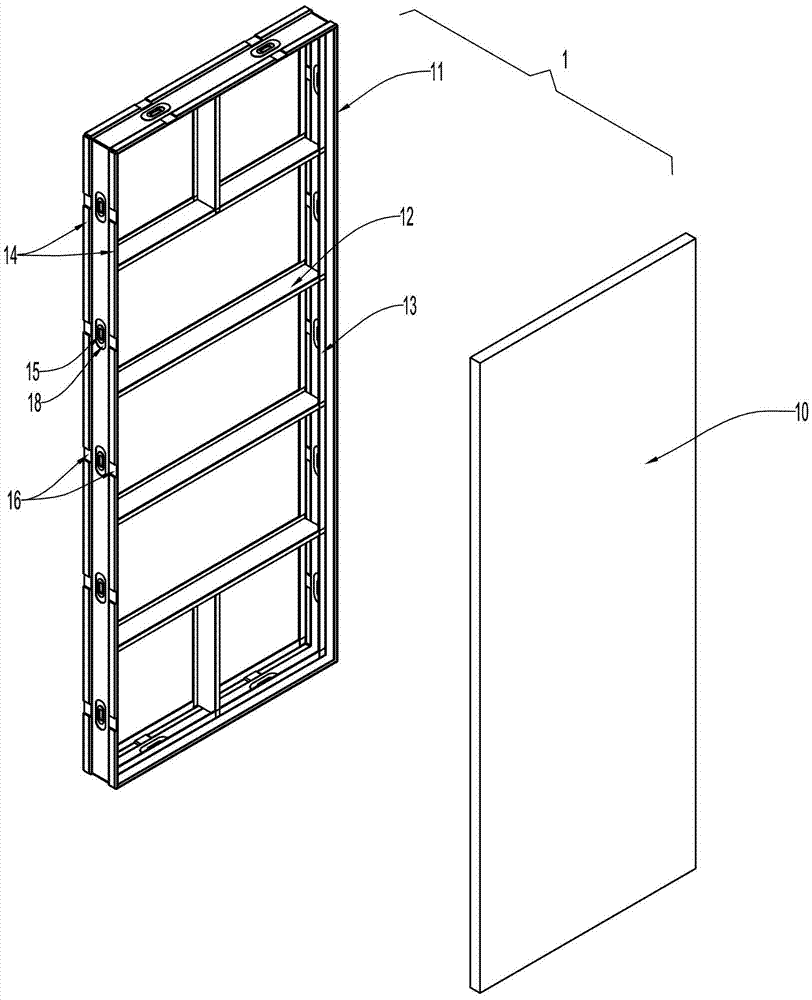

[0050] refer to figure 1 and figure 2 , steel frame formwork assembly, including steel frame formwork 1, internal corner formwork 2, external corner formwork 3, traction piece 4, splicing fastener 5, main corrugated rib fastener 6, anchor positioning piece 7, and corner fastener 8 , the steel frame formwork 1 is built on the position of the shear wall above the floor 9 . In the figure, the traction piece 4 is a long flat iron sheet, and a plurality of holes 41 are respectively provided at its two ends; the traction piece 4 can pass through the embossed parts 16 aligned with two adjacent steel frames 11; and the plurality of holes 41 The spacing is related to the designed shear wall thickness parameters; according to the thickness of the shear wall, the distance between the center of the steel frame slot 15 and the mold surface, the spacing between holes can be accurately calculated, and different wall thicknesses correspond to different hole positions, so that the constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com