Steel pipe full-encapsulating concrete pouring pipe stabilization supporting structure and construction method thereof

A supporting structure and construction method technology, applied in the direction of basic structure engineering, construction, etc., can solve the problems of difficult adjustment of installation accuracy, easy damage to the external corrosion of steel pipes, and difficult control of the radian of the pier, so as to shorten the construction period, reduce the construction of curved surfaces, The effect of avoiding destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

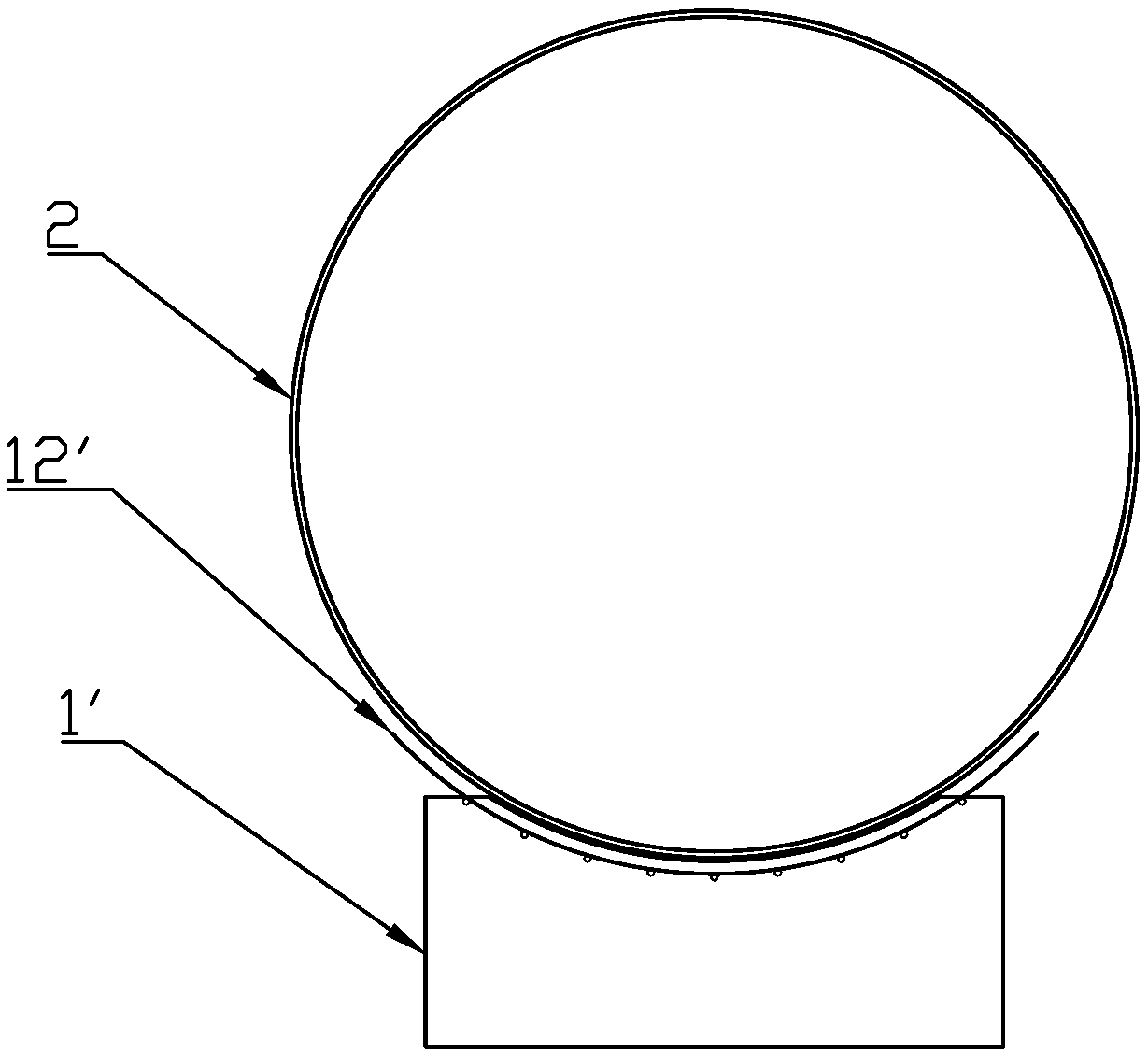

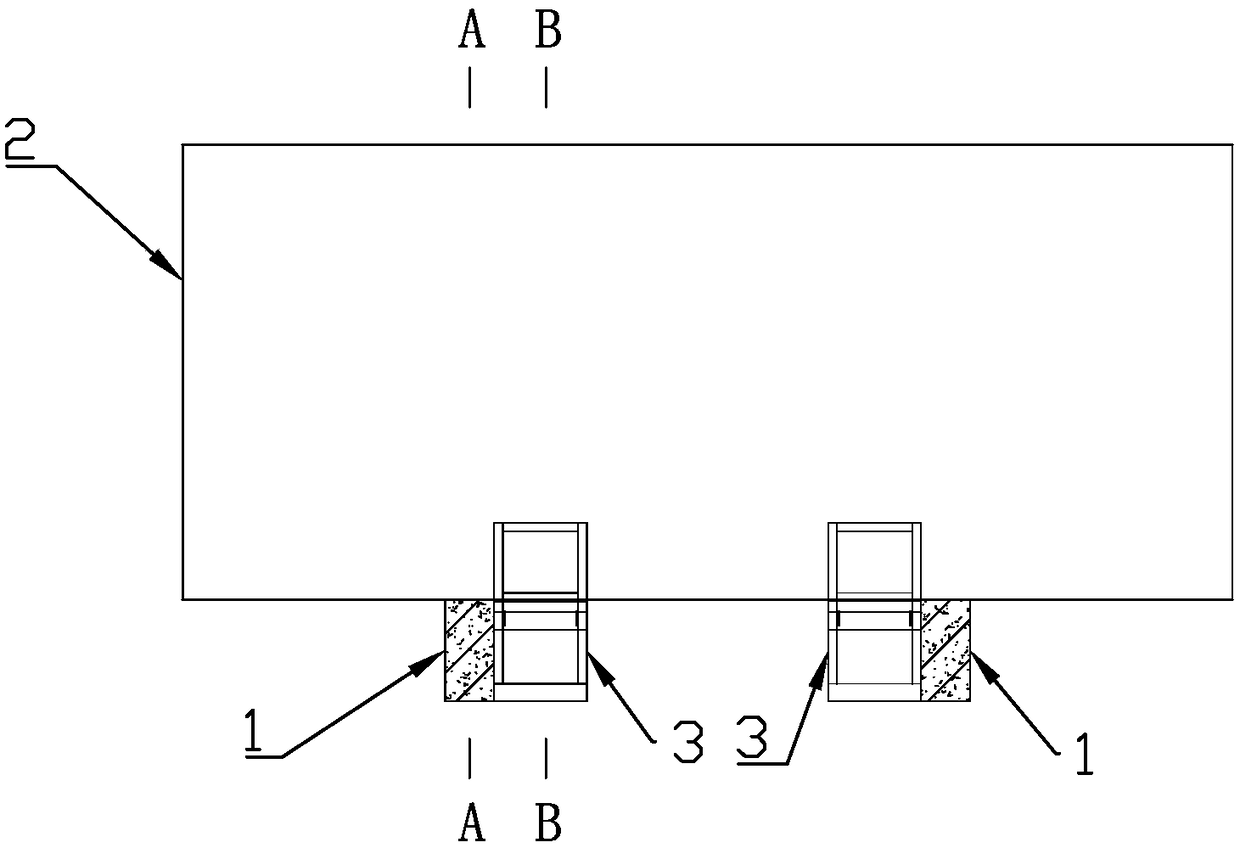

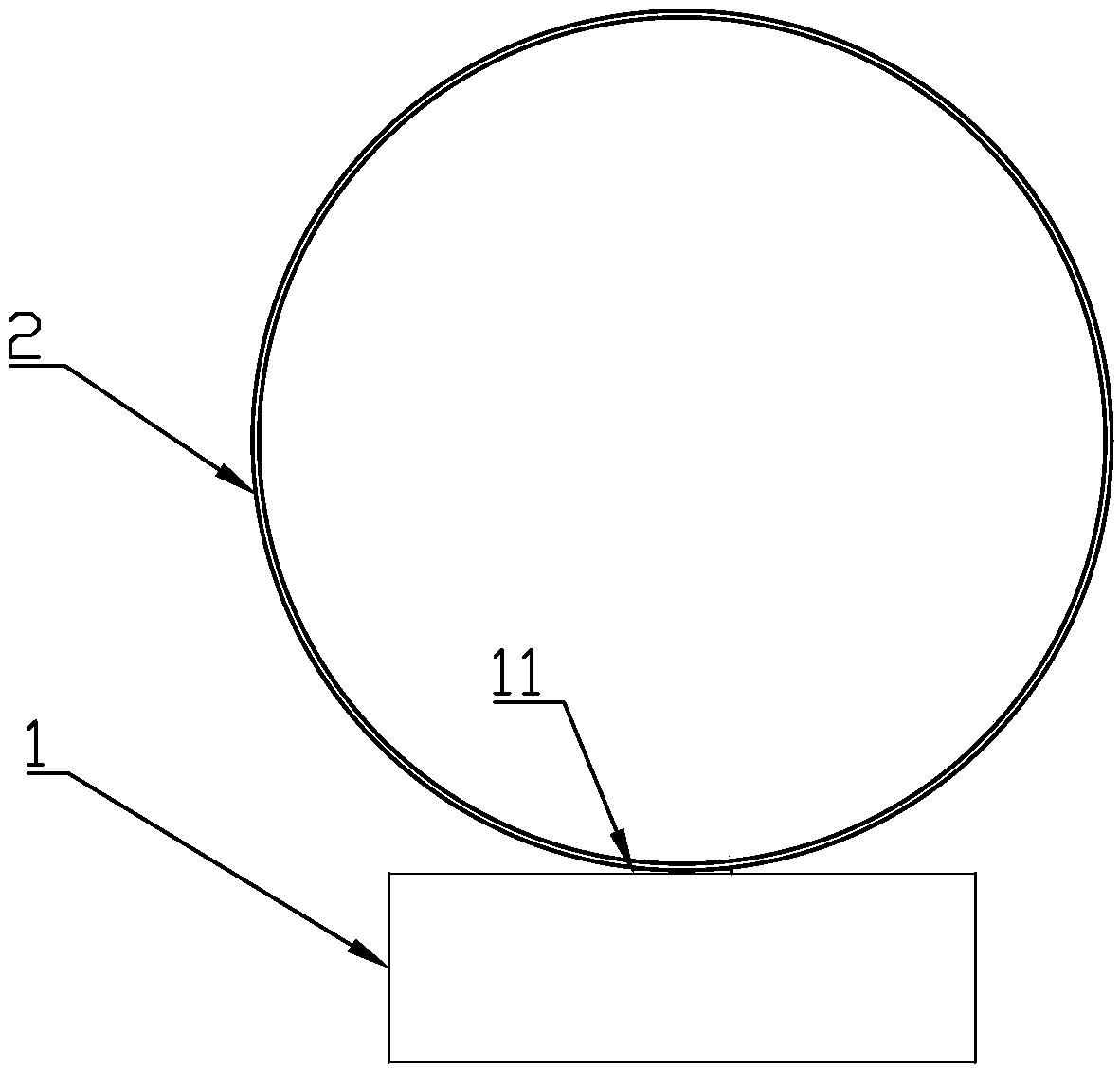

[0050] Such as figure 2 , image 3 , Figure 4 As shown, the present invention provides a steel pipe all-enclosed concrete pouring stable pipe supporting structure, which includes:

[0051] The flat-topped buttress 1 is mainly used to bear the weight of the steel pipe 2; it is preferably a rectangular parallelepiped structure, casted with reinforced concrete, in order to prevent the steel pipe 2 from being hoisted to the buttress 1 from wearing the anti-corrosion coating on the surface of the steel pipe 2 , A separable rubber cushion 11 is also provided on the upper surface of the buttress 1;

[0052] The stabilized pipe bracket 3 includes two oppositely arranged opposite pulling brackets and a tie rod 31 connected between the opposite pulling brackets. The opposite pulling bracket includes an arc-shaped steel plate 32 located above and supporting the arc-shaped steel plate 32 The base 33 is preferably welded by channel steel, and the tie rod 31 may be a steel bar connected by a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com