Self-compacting concrete pouring construction method for penetration pipe

A technology of self-compacting concrete and construction method, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc. It can solve the problems of high cost, high cost of artificial materials and equipment, and long project time, so as to achieve guaranteed installation quality and matching Guaranteed quality and reduced construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

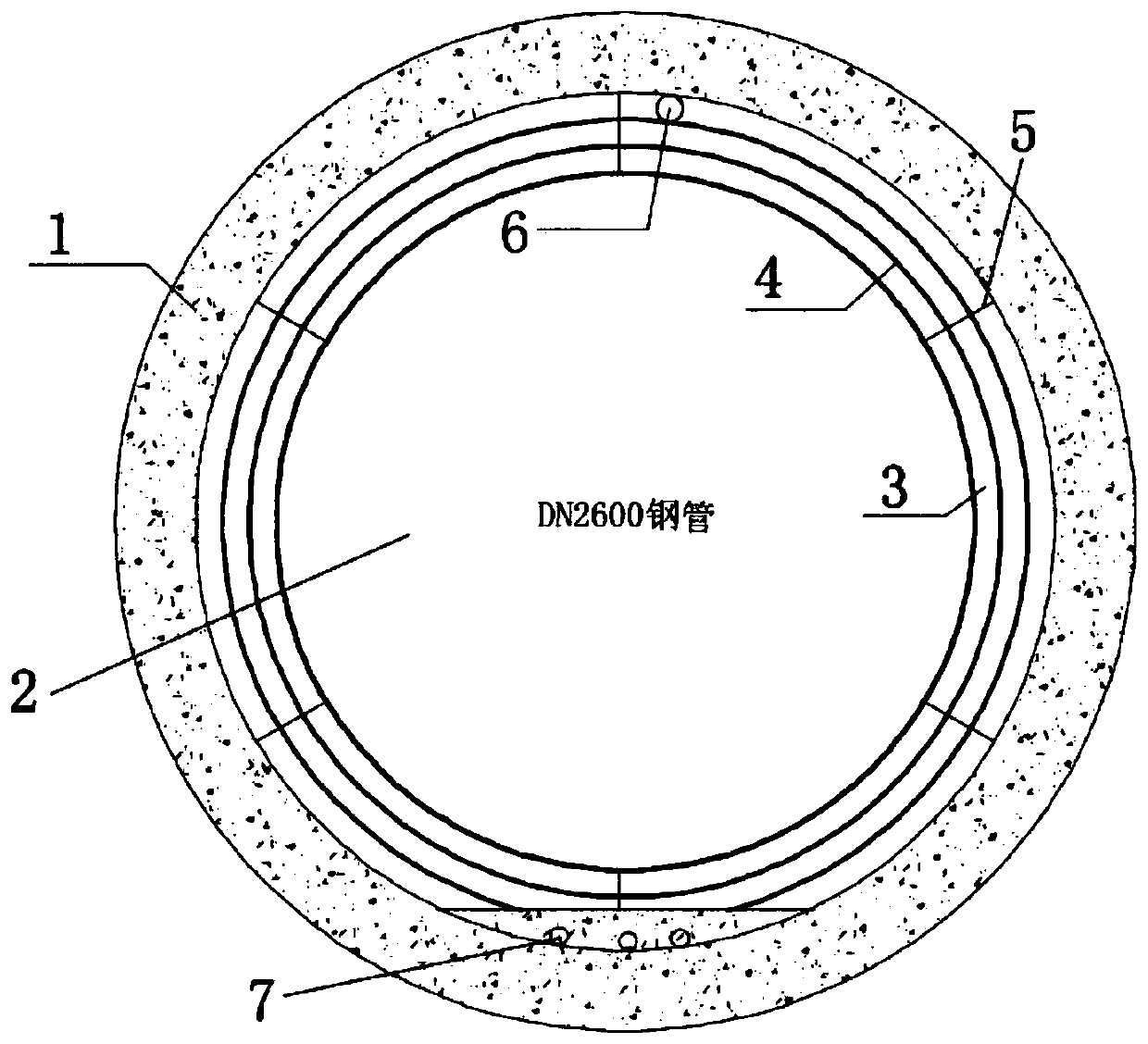

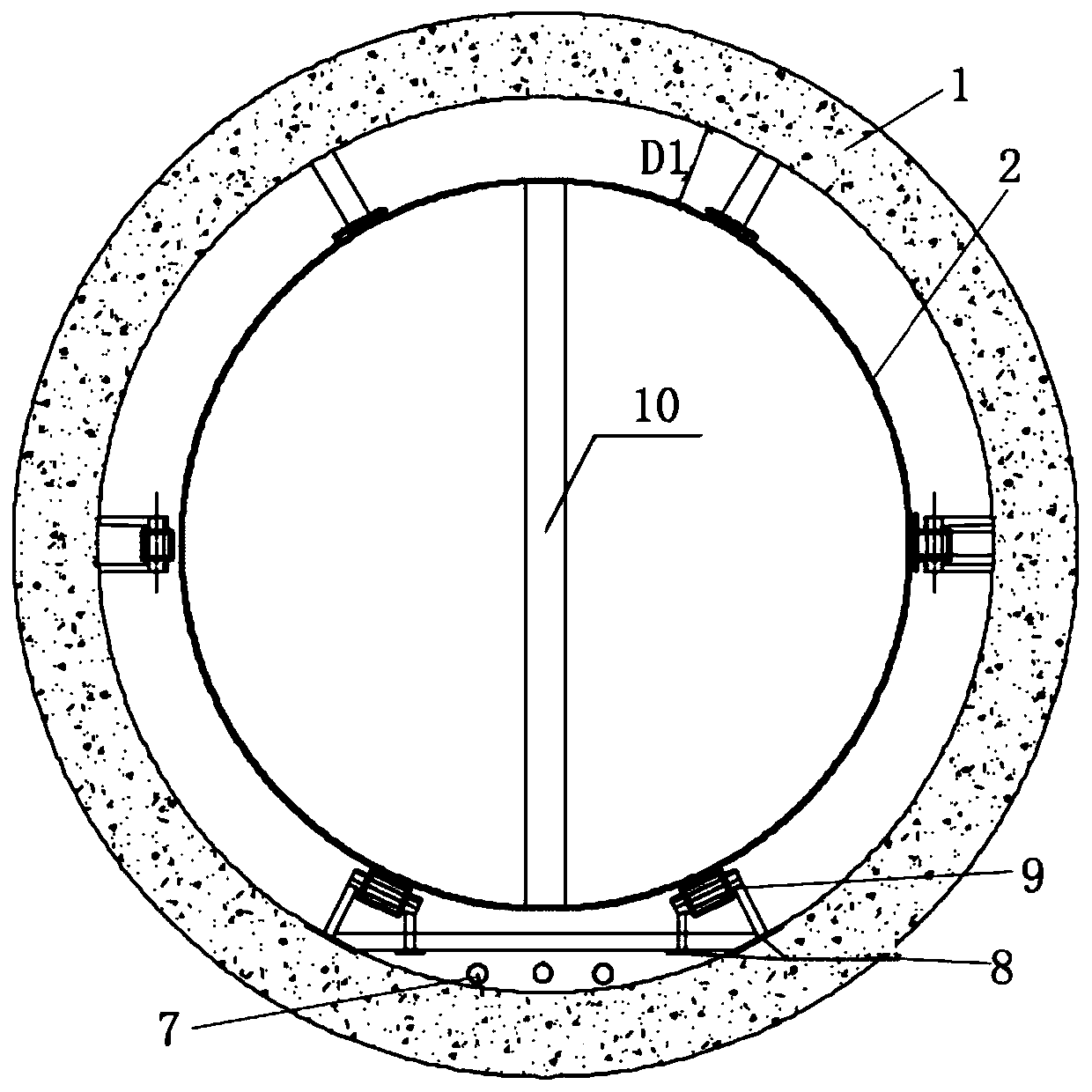

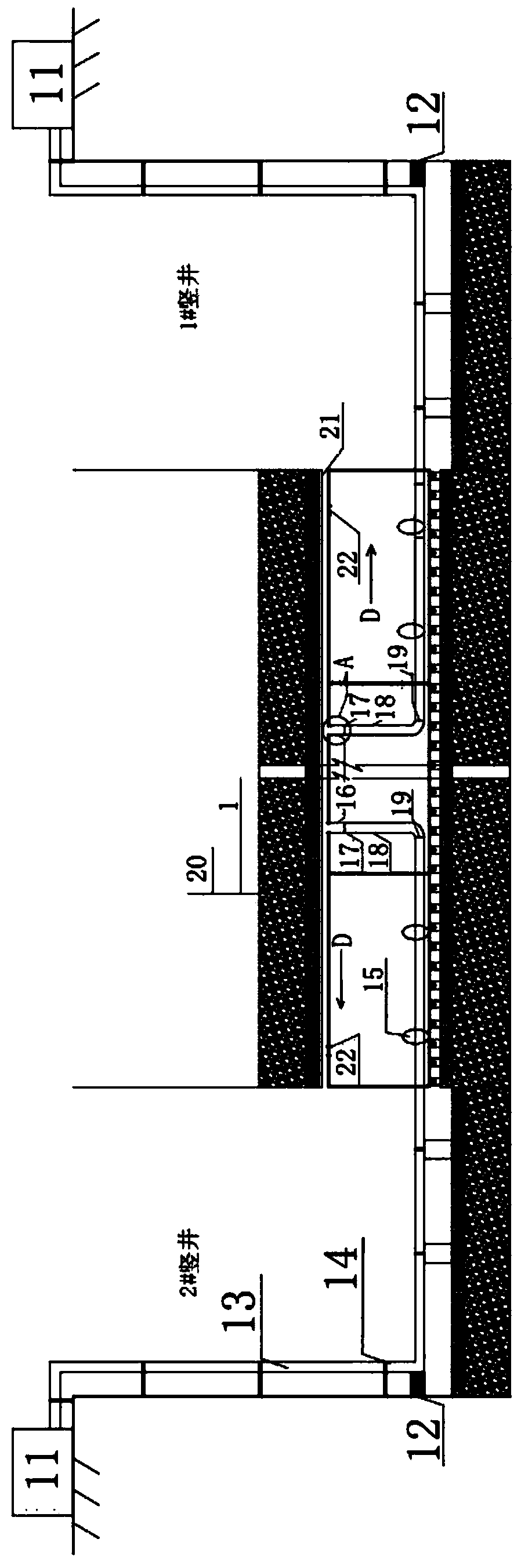

[0041] In the tunnel lining cavern, a plurality of large-diameter steel pipes connected in sequence are arranged, and the outer sides of the steel pipes at both ends are sealed with end templates, and the steel pipes are DN2600 steel pipes. Such as figure 1 As shown, in order to ensure that the end formwork of plugging is compact and does not leak slurry, the making of the end formwork is as follows:

[0042] Arrange the end formwork at the opening between the lining concrete 1 and the steel pipe 2, the end formwork is blocked with a 2cm thick bamboo plywood 3, and the outside of the bamboo plywood 3 is further equipped with a reinforcement ring 4 and a square wooden rib 5 For reinforcement, the prepared bamboo plywood 4 is fixed firmly with square wooden ribs 5 and steel bars 4, so as to prevent formwork from running when concrete is poured. Wherein, a plurality of square wooden ribs 5 are positioned at the radial direction of the steel pipe 2, and a plurality of reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com