Concrete post provided with counter pulling sheet profile steel welding rectangular steel tube

A technology for rectangular steel pipes and concrete columns, applied in the directions of columns, piers, pillars, etc., can solve the problems of increasing the number of welds between longitudinal stiffeners and steel plates, processing difficulties, and high construction costs, reducing wall thickness and reducing welds. Quantity, the effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

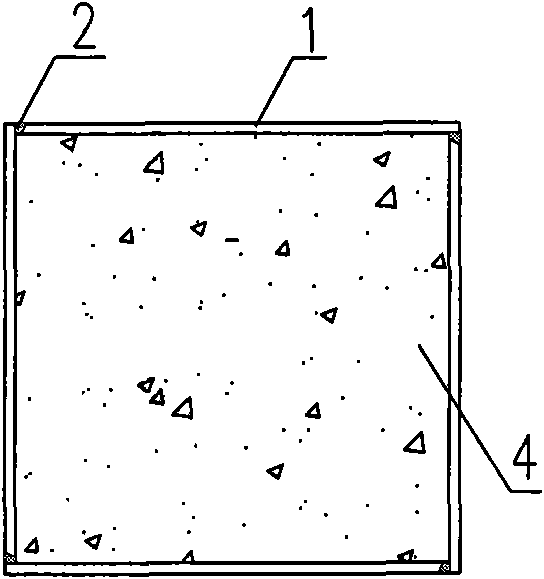

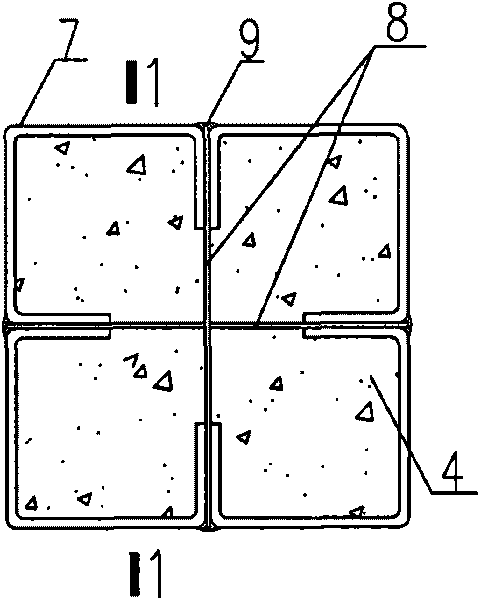

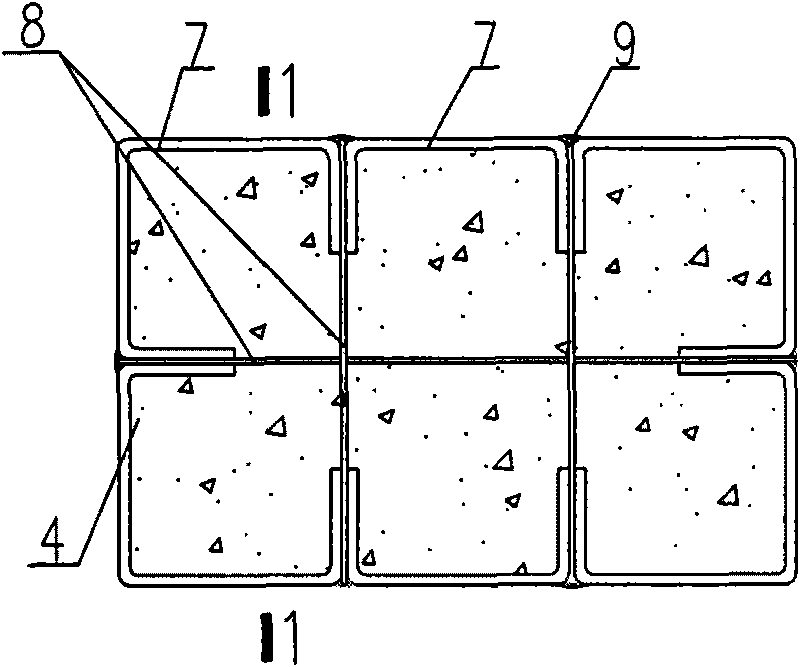

[0032] The present invention is made up of steel pipe and concrete 4, and steel pipe is made up of profiled steel 7 with rib 6 and transversely arranged opposite pull sheet 8 through welding, is welded on steel pipe to form weld seam 9, and profiled steel 7 is straight rib or oblique rib, and its cross-section Schematic such as Figure 5-8 As shown, the form of the pull piece 8 used in the steel pipe is as follows Figure 9 As shown, the pair of pull tabs 8 are vertically spaced and vertically staggered. During application, the shape and quantity of section steel 7 can be adjusted, selected and combined according to the actual size, and the cross-section of the obtained rectangular steel tube concrete column is as follows Figure 10-13 Shown:

[0033] Figure 10 Among them, the steel pipe is welded by the pull piece and the straight rib steel, and together with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com