Suspension bridge sectional-type catwalk and construction method thereof

A construction method and technology for suspension bridges, applied to suspension bridges, bridge forms, bridges, etc., can solve the problems of inconvenient erection of main cable strands, inconvenient hanging and dismantling of catwalks, and difficulty in adjusting the line shape of load-bearing cables, etc., and achieve simplified erection and alignment adjustment process, shortened erection time, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

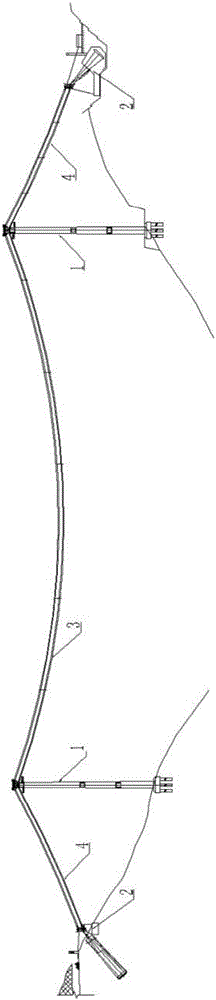

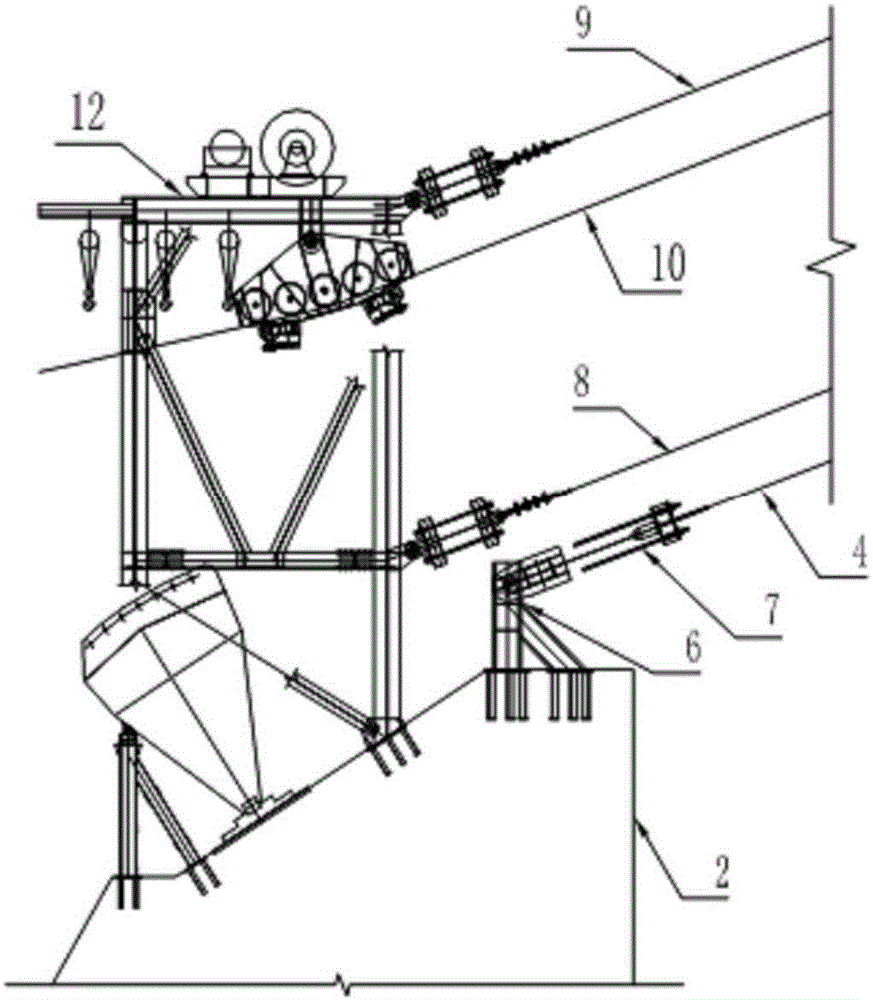

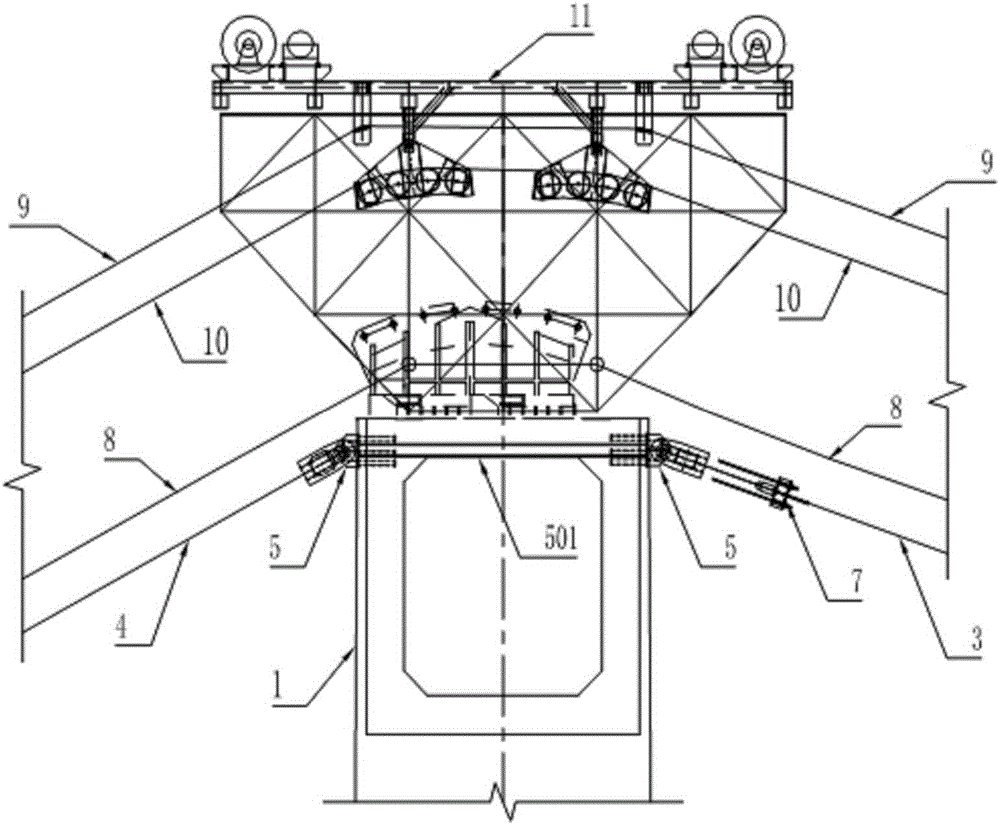

[0029] see Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a segmented catwalk for a suspension bridge, which is used to connect two main towers 1 located on both sides of the main span of the suspension bridge and anchorages 2 located on both sides of the suspension bridge,

[0030] A first anchoring device 5 is fixed on both sides of the main tower 1, and the two first anchoring devices 5 of the same main tower are connected by a tensioning device 501 embedded in the main tower 1. A main span load-bearing cable 3 is connected between the two opposite first anchoring devices 5;

[0031] The anchorage 2 is provided with a second anchoring device 6, and a side span load-bearing cable 4 is connected between the second anchoring device 6 and the first anchoring device 5 of the main tower 1 opposite to it.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com