Gob-side entry driving small coal pillar anti-impact pressure-releasing and counter-pulled anchoring integrated structure and construction method thereof

A technology of small coal pillars and anti-scouring, which is applied in the direction of earthwork drilling, bolt installation, and mining equipment. The number of holes and the effect of consolidating safe production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

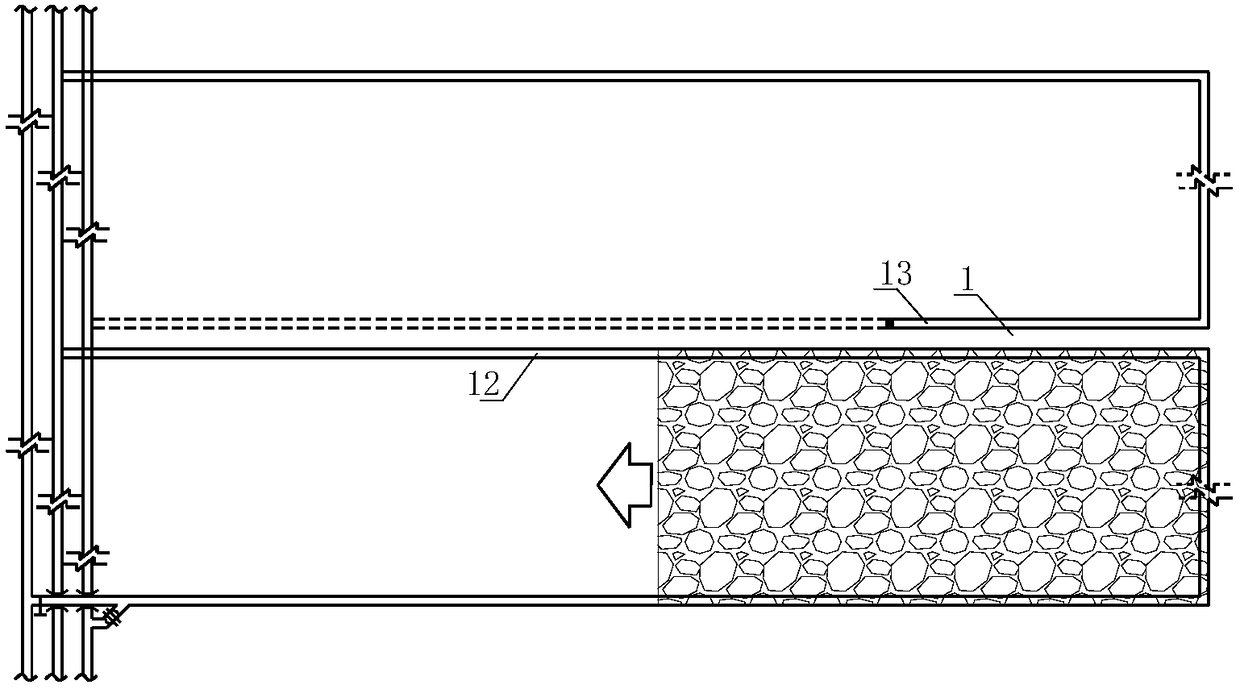

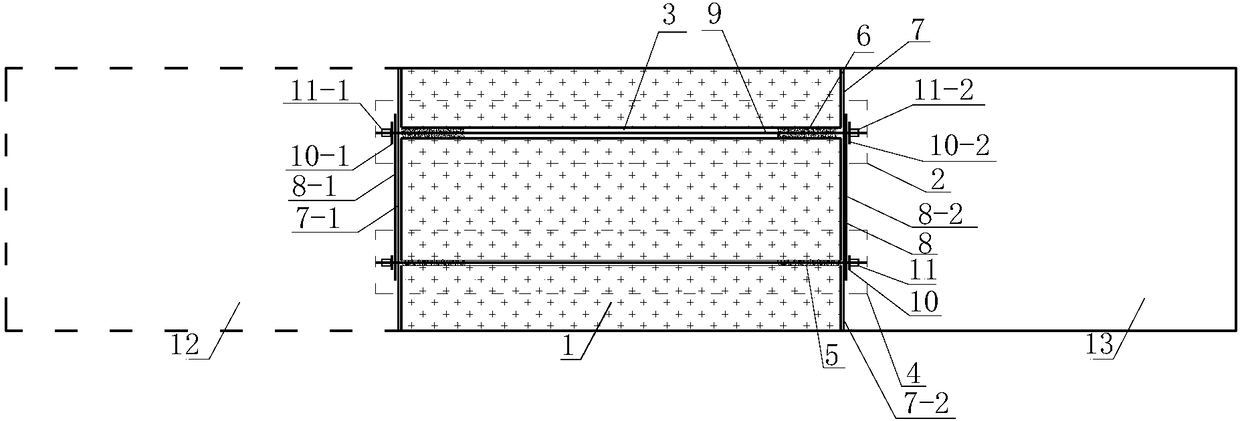

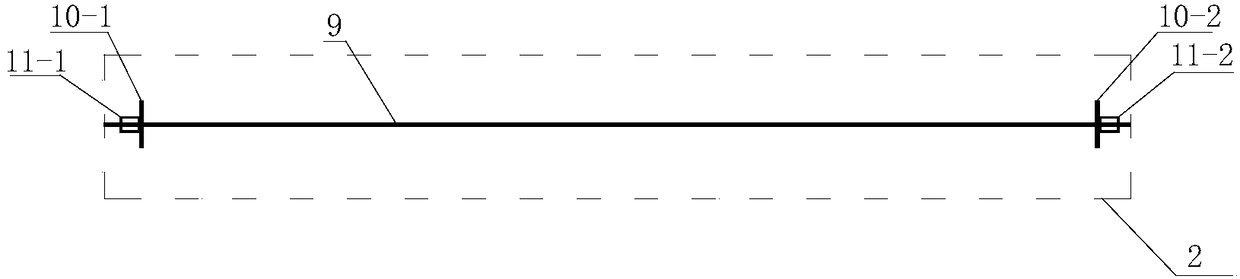

[0027] Coal mine A adopts anti-scouring, pressure relief, anti-scouring, pressure relief, anti-scourt, tension and anchoring integrated structure and construction method when setting small coal pillars along the gob-side roadway. Coal mine A is mining 3 coals. The average thickness of 3 coals is 5m, near the horizontal coal seam, and the buried depth is about 500m. Two troughs are arranged on the working face, which are the transport trough and the return air trough. The return air chute of the 30104 working face adopts gob-side digging, and a small coal pillar is left between the return air chute of the 30104 working face and the transportation chute of the 30102 working face, and the width of the small coal pillar is 6m. 3. The coal is identified as a coal seam with a weak impact tendency, and the integrated structure of anti-scouring, pressure relief, tension and anchorage is applied to this working face when implementing gob-side entry.

[0028] The construction method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com