Hoisting method for equipment installation in in-between hollow space of multilayer concrete platforms

A technology for installing concrete platforms and equipment, applied in hoisting devices, clockwork mechanisms, cranes, etc., can solve the problems of narrow equipment installation space, affecting the safety of construction personnel and equipment, and inconvenient hoisting methods, so as to ensure safety, The effect of safe hoisting in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

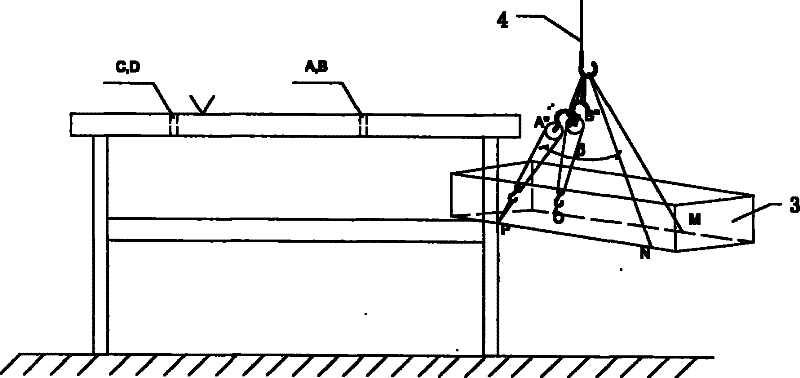

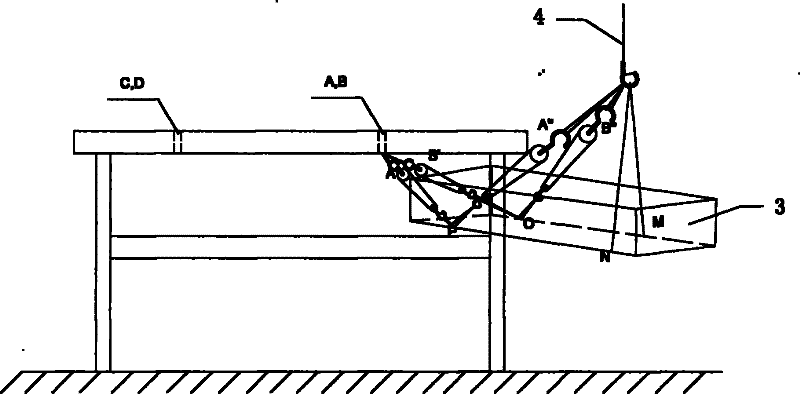

[0028] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0029] The hoisting method of the present invention for installing equipment in the hollow interlayer of a multi-layer concrete platform has been successfully applied in Baosteel’s stainless steel pickling unit. The safety of facilities and personnel, without any collision.

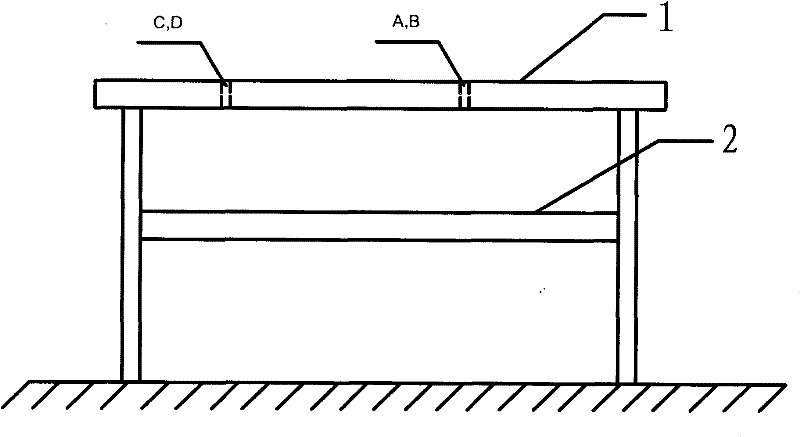

[0030] Shanghai Baosteel's stainless steel cold-strip annealing and pickling units are mostly imported equipment, with a total of more than 3,200 tons of equipment, of which 16 sets of equipment are located on the second floor of the concrete three-story platform, and the space is extremely narrow. One of the notable features is the multi-layer production line Distribution, the total length of the process line is 1134m, and it adopts a compact multi-layer layout. The land occupation is compressed to 414m, and it is divided into three floors. The elevation of the third-floor platform is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com