Hoisting method of equipment located on the bottom layer of multi-layer frame platform

A technology of underlying equipment and hoisting methods, which is applied in the direction of transportation, packaging, and walking bridge cranes, cranes, etc., can solve the problems of instability and dumping, long moving distance, inconvenience, etc., to ensure the safety of operators and equipment, and facilitate hoisting In place effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

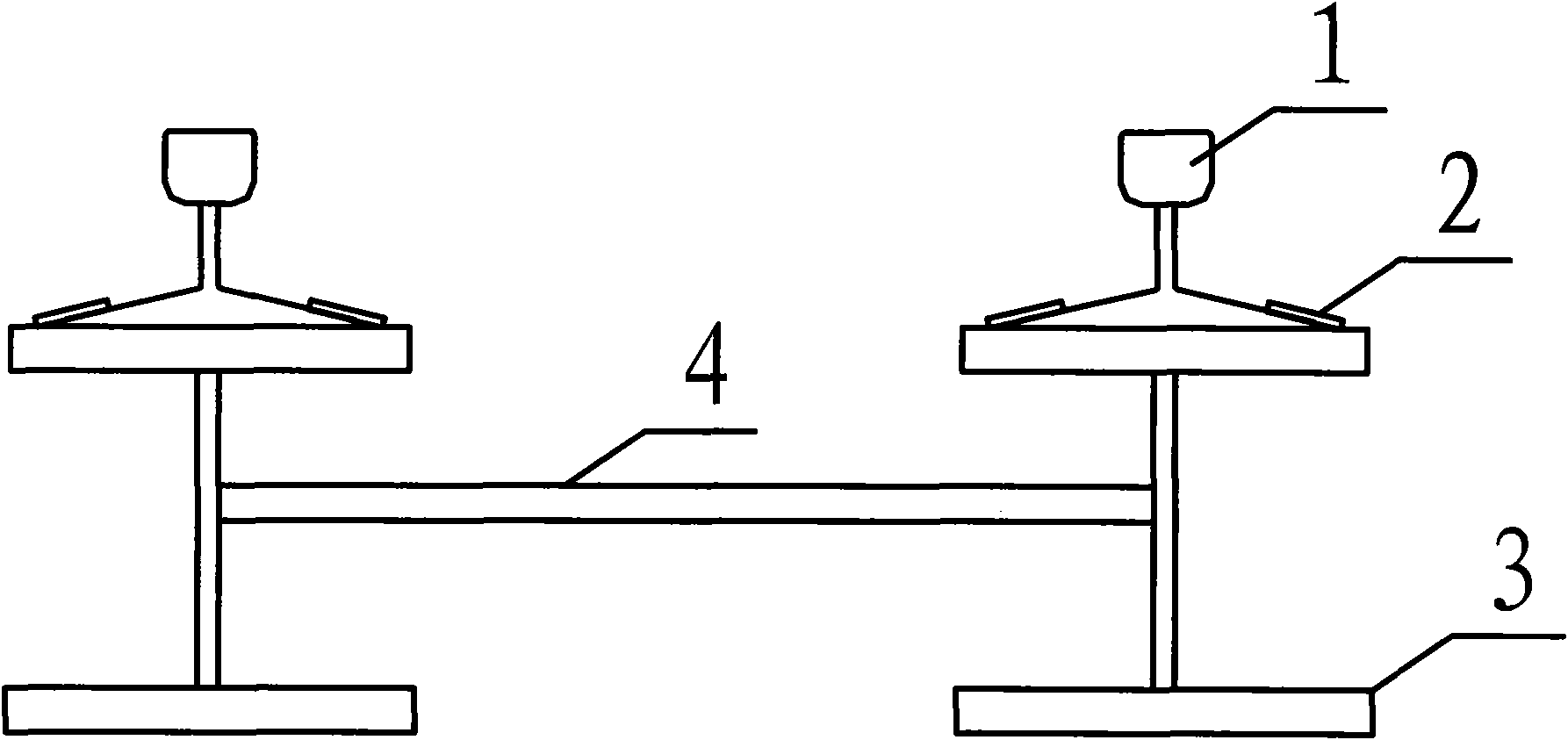

[0031] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0032] The hoisting method of the equipment located at the bottom layer of the multi-layer frame platform of the present invention is successfully applied in Baosteel's stainless steel cold annealing and pickling line. When the entire unit line is more than 400 meters long, there are more than 100 ground floor equipment located under the frame platform, and some ground foundations have trenches, which cannot be directly installed by hoisting and rolling bars, the multi-level equipment of the present invention is adopted. The hoisting method of the bottom equipment of the layer frame platform has high installation efficiency, and the total construction period of equipment installation has been shortened by 10 days compared with the original plan, which has regained the overall progress node and ensured the safety of the hoisted equipment, surrounding facilities...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com