Steel beam lifting device and steel beam lifting method for flexible sliding form platform

A technology for hoisting devices and steel girders, which is applied in hoisting devices, transportation and packaging, portable lifting devices, etc., can solve problems such as low construction efficiency and lack of effective lifting devices, and achieve improved hoisting efficiency, high hoisting efficiency, The smooth effect of the lifting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0061] Furthermore, as a specific embodiment of the steel beam hoisting method provided by the present invention, the lateral adjustment tool is a crowbar.

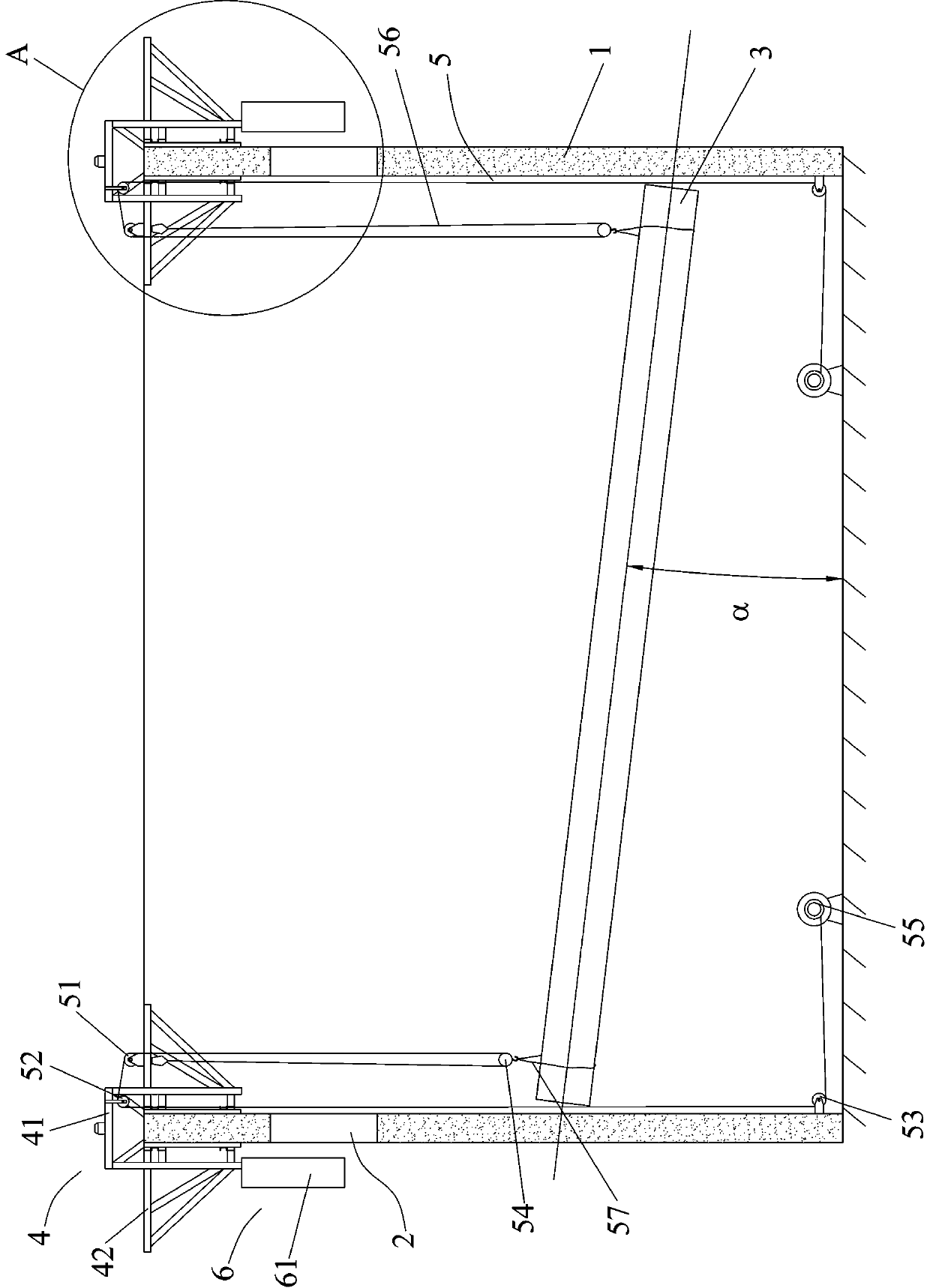

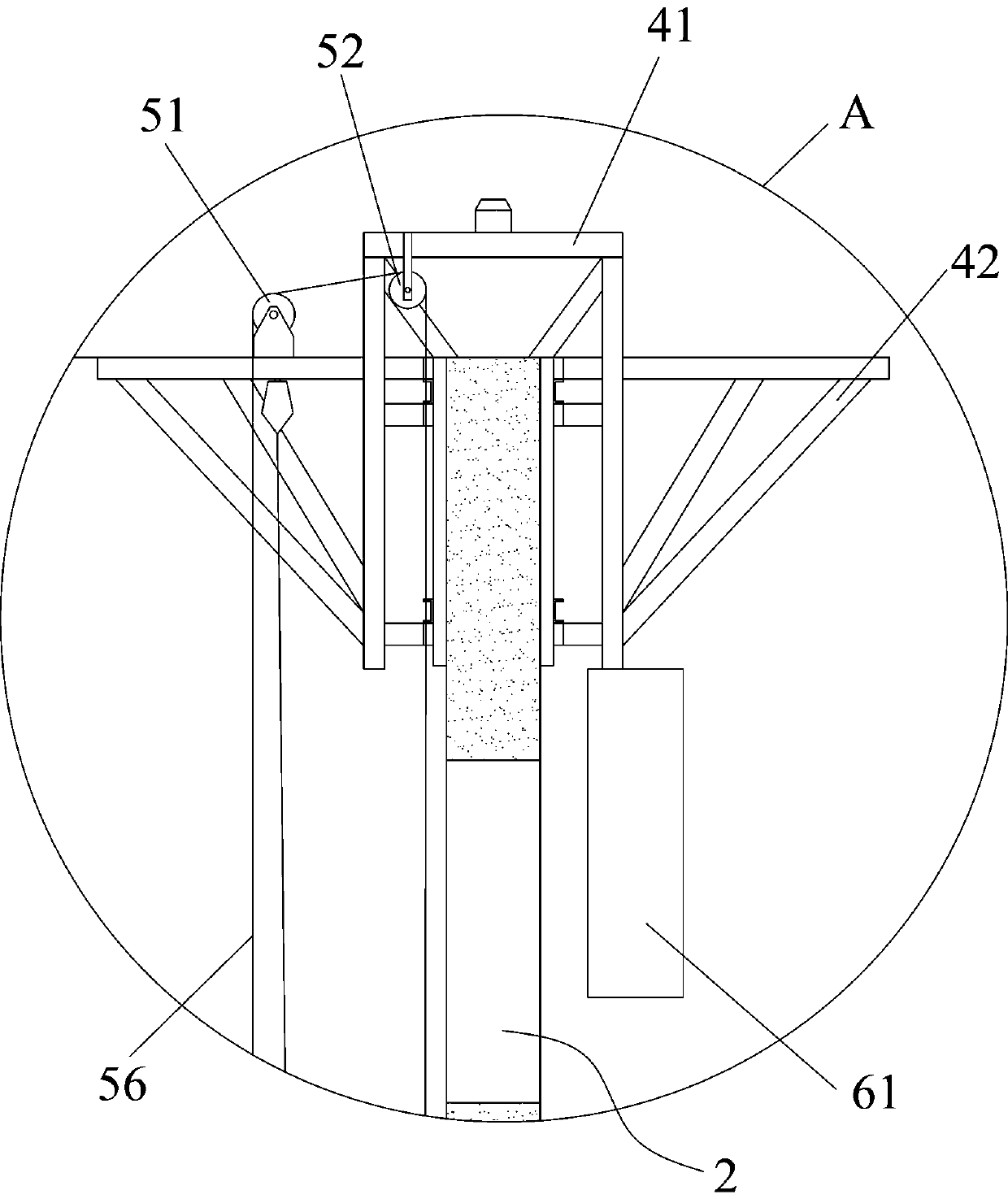

[0062] according to Figure 3 to Figure 8 , define the first side as the left side, the second side as the right side, the first end as the left end, and the second end as the right end. The specific usage process can be:

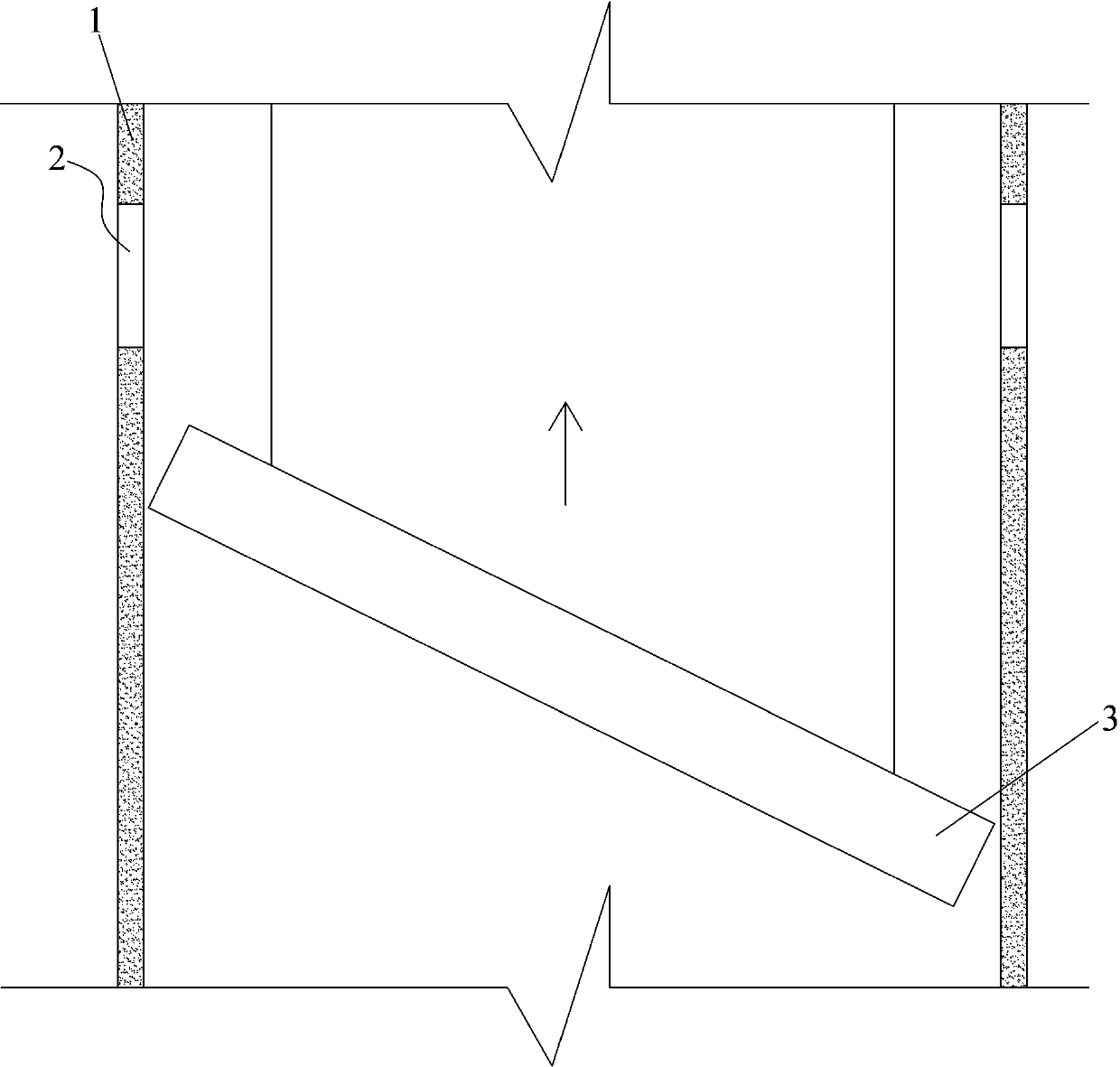

[0063] 1) The two ends of the steel beam 3 are respectively connected to the suspension rings 57 located on both sides inside the silo main body 1;

[0064] 2) Lift the left end of the steel beam 3 through the lifting ring 57 located on the left side of the silo main body 1, so that the left end of the steel beam 3 is higher than the right end of the steel beam 3, and the long axis of the steel beam 3 forms an acute angle α with the ground;

[0065] 3) Synchronously lift the left end and right end of the steel beam 3 through the lifting ring 57 on the left side of the silo main body 1 and the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com